Impermeable concrete and construction method thereof

An impermeable concrete and cement technology, which is applied to tools, buildings, roofs, etc. for roof engineering, can solve the problems of long-term crack resistance and impermeability of the roof structure, and achieve improved structural performance, low cost, and improved resistance to osmotic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

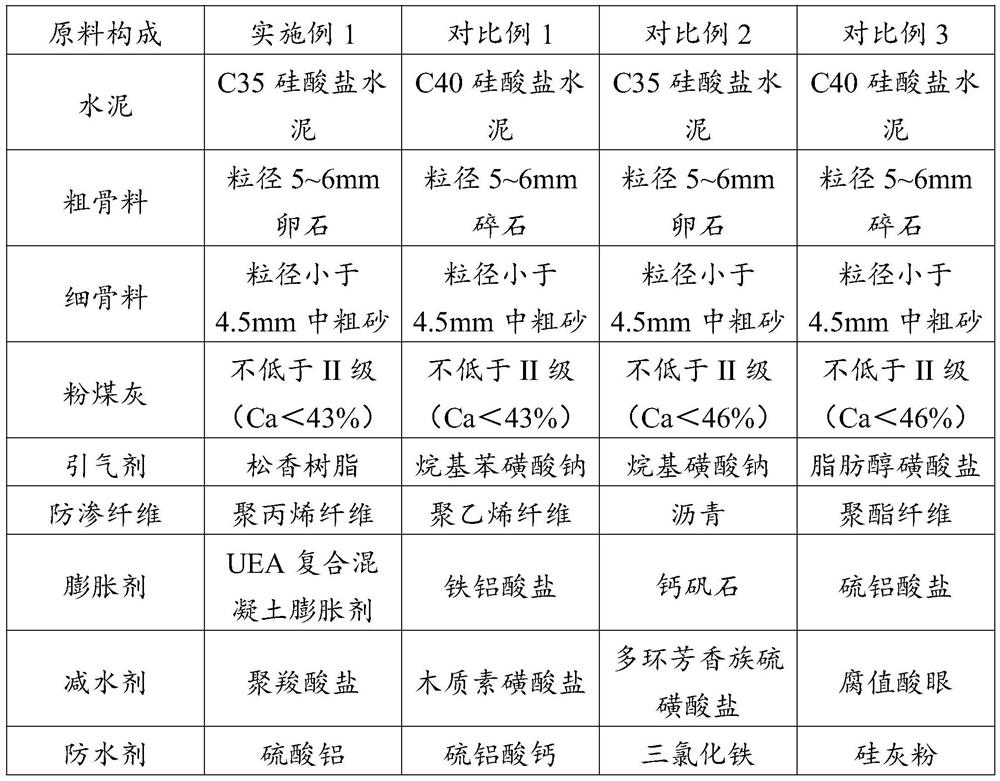

Examples

preparation example Construction

[0030]In the present invention, the air-entraining agent is preferably rosin or rosin condensation polymer. The preparation method of the rosin polycondensate of the present invention preferably comprises: rosin and lignin are heated and melted and mixed homogeneously, and isomerized to obtain an isomerized product A; to the isomerized product A, maleic anhydride or maleic anhydride and Concentrated sulfuric acid is polycondensed to obtain synthetic resin B; polyethylene glycol is added to resin B, and glycerol and / or concentrated sulfuric acid is added to graft esterification to obtain esterification product C; foam stabilization is added to esterification product C Components, heat preservation reaction; cooling, alkali solution neutralization, controlling pH = 8-13, heat preservation reaction, adding tap water dropwise, making the solid content 30±1%, and preparing the air-entraining agent of rosin condensation polymer. The rosin condensation polymer air-entraining agent pr...

Embodiment 1

[0049] A kind of anti-seepage concrete, its raw material comprises the composition of following weight part: 100 parts of cement, 330 parts of coarse aggregate, 250 parts of fine aggregate, 65 parts of fly ash, 30 parts of admixture (6 parts of air-entraining agent, anti-seepage 6 parts of fiber, 6 parts of swelling agent, 6 parts of water reducing agent, 6 parts of waterproofing agent), 55 parts of water; the specific raw materials of this embodiment are shown in Table 1.

[0050] The construction method of above-mentioned anti-seepage concrete comprises the steps:

[0051] Mix cement, coarse aggregate, fine aggregate, and fly ash with water; add air-entraining agent, anti-seepage fiber, expansion agent, water-reducing agent, and water-repellent in sequence and mix evenly to obtain impermeable concrete; pour the impermeable concrete into For the roof with steel structure, the large-area base and roof are poured in groups, and the pool wall is poured continuously in layers; af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com