Intelligent track type freely-combined washing line

A combined and orbital technology, applied in the field of washing machines, can solve the problems of narrow space in the transmission connection channel, difficult maintenance and troubleshooting, and achieve the effect of flexible adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

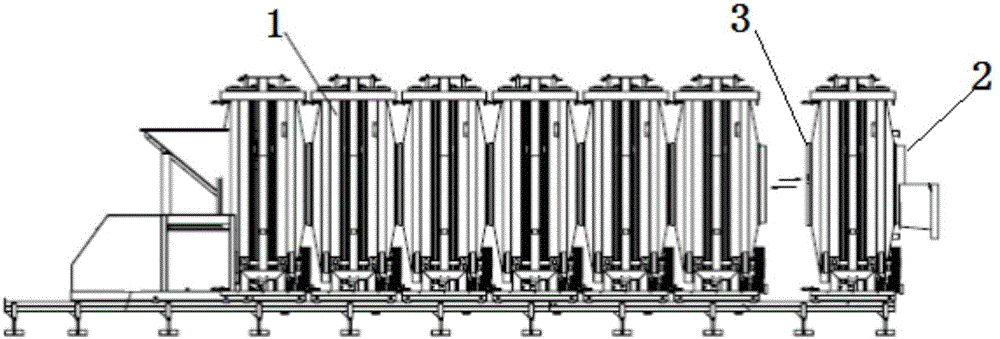

[0032] see figure 1 , the intelligent rail-type free combination washing dragon, including a washing unit, the washing unit includes at least two washing bins 1; the right side of the washing bin is provided with a material inlet 2, and the left side of the washing bin is provided with a discharge port 3, The width of the discharge port 3 is greater than the width of the feed port 2, and at least two washing chambers 1 are connected to the feed port 2 through the discharge port 3; The transmission mechanism is connected with the washing chamber. The invention guarantees that the respective rotations of the washing bins do not affect each other through the plugging of the outlet 3 of the washing bin and the feeding port 2, and the washing bins can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com