Removing-column spatial expansion structure for column-and-tie wood constructions and implementation method of removing-column spatial expansion structure

A technology of space expansion and wooden frame, which is applied in the field of space expansion structure of bucket-through wooden frame with column extraction, can solve the problems of limited continuous use space and column network layout that cannot meet the use requirements, so as to increase social and economic benefits, increase The effect of continuous and effective use of space and optimization of force distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

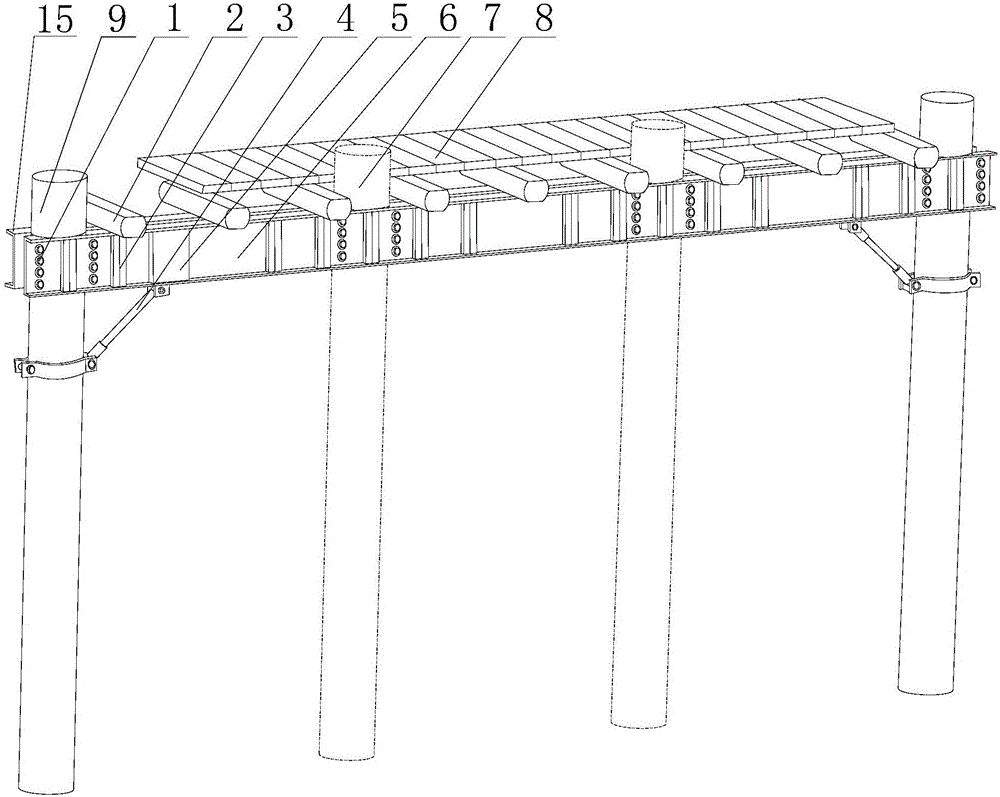

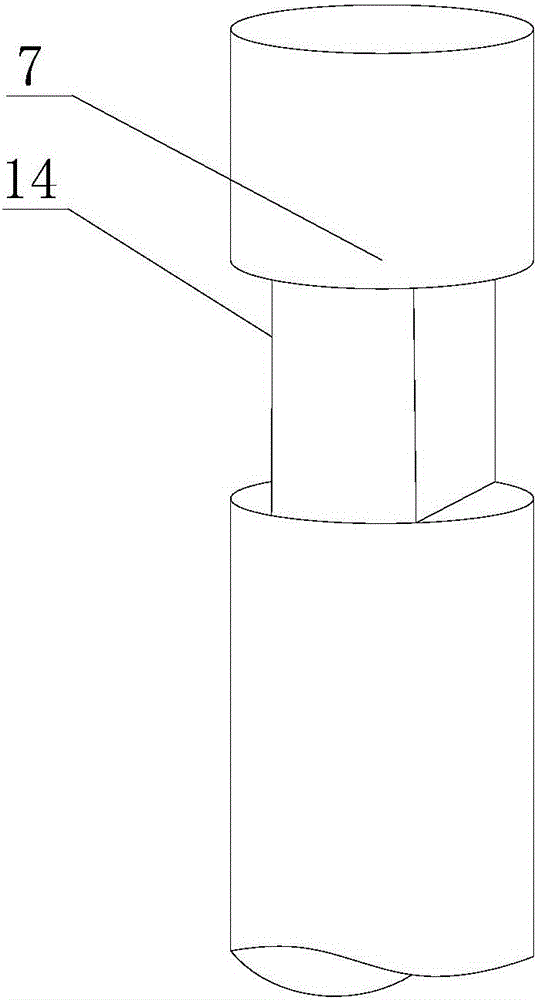

[0034] Such as Figure 1~4 As shown, this embodiment includes two side columns 9, and the side walls of the side columns 9 are provided with card slots 14, and also includes a piercing frame I6 and a piercing frame II15, and the piercing frame I6 is fixed on the two side columns 9 In the slot 14 on the same side wall, the piercing frame II 15 is fixed in the slot 14 on the other side wall of the two side columns 9, and the side column 9 is provided with the piercing frame I 6 , Wear the support member 4 connected at the bottom of Fang II 15. In the existing bucket-through wooden frame, the vertical load-bearing structure is composed of two side columns 9 and a plurality of middle columns 7, and the side columns 9 and the middle columns 7 are connected by the original piercing frame 16, and the floor slab 8 is laid on Building 2 is above the building 2, and building 2 is distributed on the original piercing frame 16. Due to the small size of the vertical load-bearing members o...

Embodiment 2

[0036] Such as Figure 1~3 As shown, this embodiment is on the basis of Example 1. Both the piercing frame I6 and the piercing frame II15 are channel steel, and the piercing frame I6 is connected to the piercing frame II15 through a plurality of bolts 1; A plurality of T-shaped stiffeners 3 are arranged on the grooved side of the frame II 15; antique decorative wood 5 is arranged on the outer wall of the stiffeners 3.

[0037] As a preference, channel steel is used to replace the original piercing frame 16, and the piercing frame I6 and piercing frame II15 connected by bolt 1 form a whole, which can not only replace the connection function of the original piercing frame 16, but also significantly increase the strength Wholeness.

[0038] The piercing frame I6 and the piercing frame II15 are set back to back, that is, the slotted sides on both sides are facing outwards, and a plurality of T-shaped stiffeners 3 are arranged on the slotted side, which can further increase the lo...

Embodiment 3

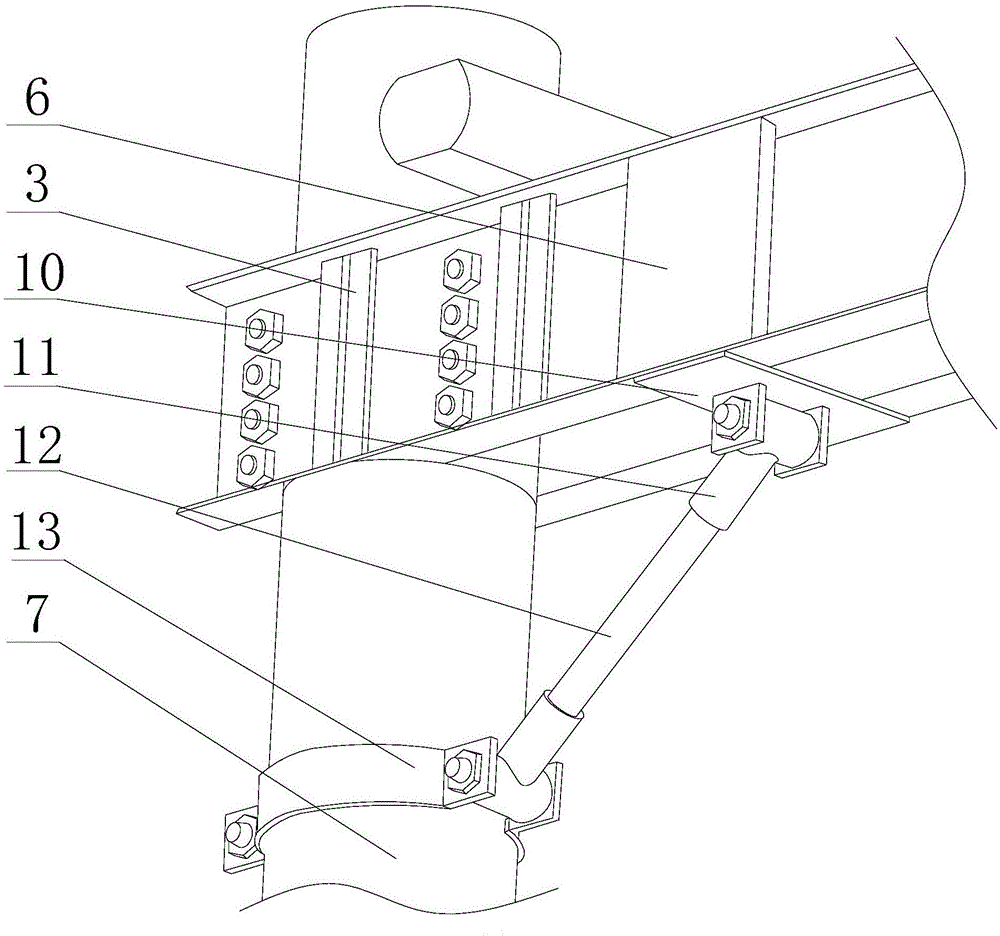

[0041] Such as figure 2 As shown, the support member 4 in this embodiment includes an upper support 10, a connecting rod 12 and a lower support 13, the upper support 10 is fixed on the bottom of the piercing frame II 15 and the piercing frame I 6, and the lower support 13 It is arranged on the side column 9 , and the upper support 10 and the lower support 13 are hingedly provided with connecting pieces 11 , and the two ends of the connecting rod 12 are respectively connected with the two connecting pieces 11 .

[0042] The upper support 10 merges and connects the piercing frame II 15 and the bottom of the piercing frame I6, and sets the lower support 13 on the side column 9, and the two ends of the connecting rod 12 are respectively connected with connecting pieces 11, and the two connecting pieces 11 are respectively connected with The upper support 10 and the lower support 13 are hinged, that is, according to the specific layout of the bucket-type wooden frame dwelling, sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com