Rod Lifting Method

A technology of rods and lifting ropes, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of uneven force, easy to break and swing range, etc., and achieve the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

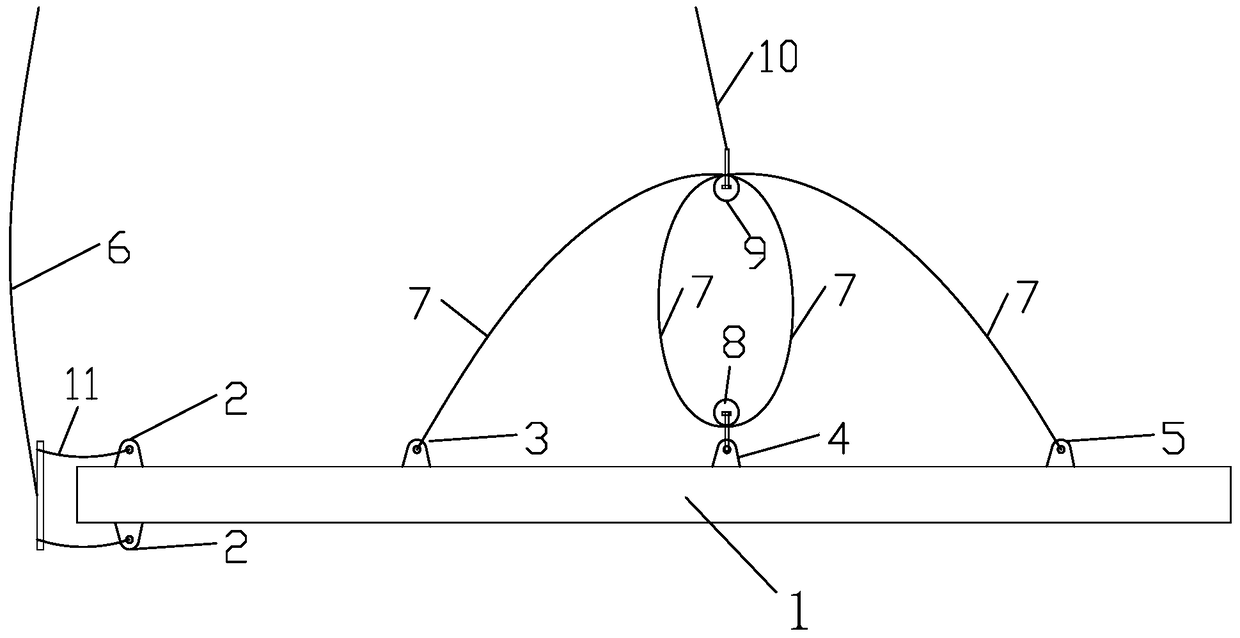

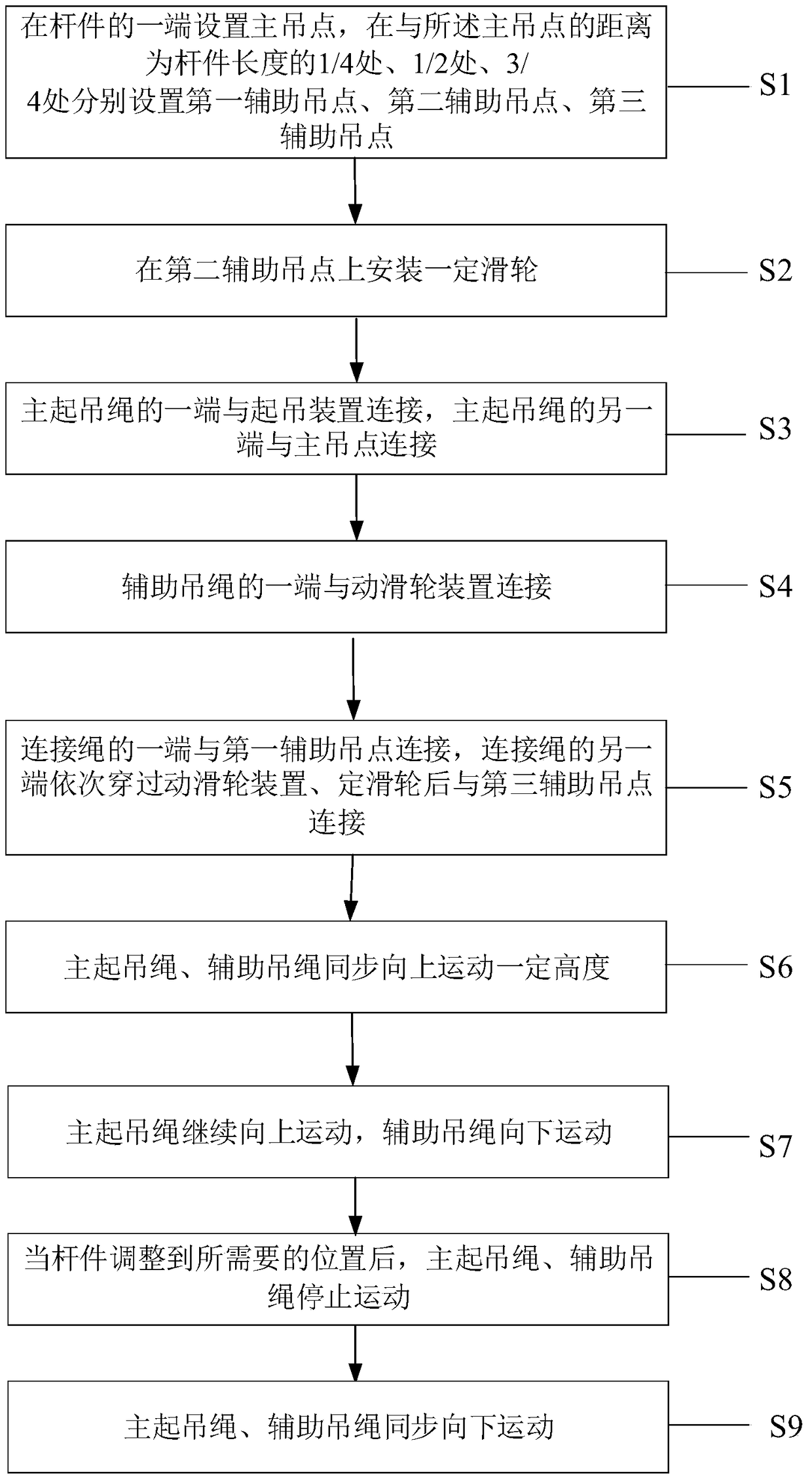

[0035] Please combine Figure 1-2 It should be understood that a rod lifting method includes the following steps:

[0036] S1: Set the main lifting point at one end of the rod 1, the main lifting point includes a pair of symmetrically arranged main lifting point fixing rings 2, and the first auxiliary lifting point at a distance of 1 / 4 of the length of the rod from the main lifting point. An auxiliary lifting point fixing ring 3 is set on the lifting point, and the distance from the main lifting point is 1 / 2 of the length of the rod. An auxiliary lifting point fixing ring 4 is set on the second auxiliary lifting point, and the distance from the main lifting point is 1 / 2 of the rod length Auxiliary lifting point fixing ring 5 is set on the third auxiliary lifting point at 3 / 4 of the length;

[0037] S2: Install a certain pulley 8 on the fixing ring 4 of the auxiliary lifting point;

[0038] S3: The connecting rod 11 is used to realize the connection between the main lifting r...

Embodiment 2

[0046] Other parts of this embodiment are the same as Embodiment 1, and its special feature is that the main hoisting rope 6 and the auxiliary hoisting rope 10 are all steel wire ropes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com