A vehicle-mounted automatic packaging mechanism for membranes

A vehicle-mounted, film-body technology, which is applied in the field of vehicle-mounted film-body automatic packaging mechanisms, can solve problems such as no discovery, and achieve the effects of improving packaging efficiency and saving labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

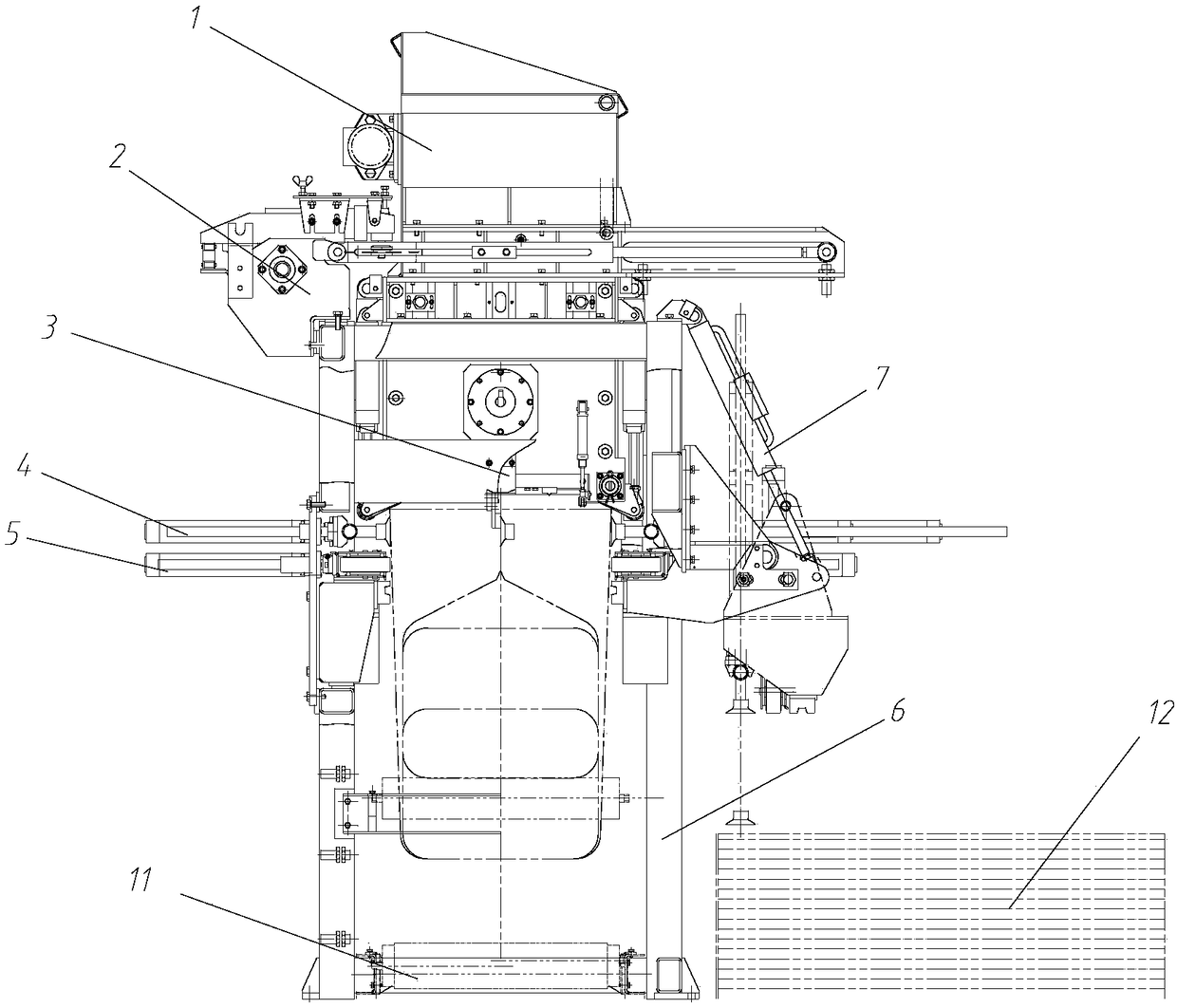

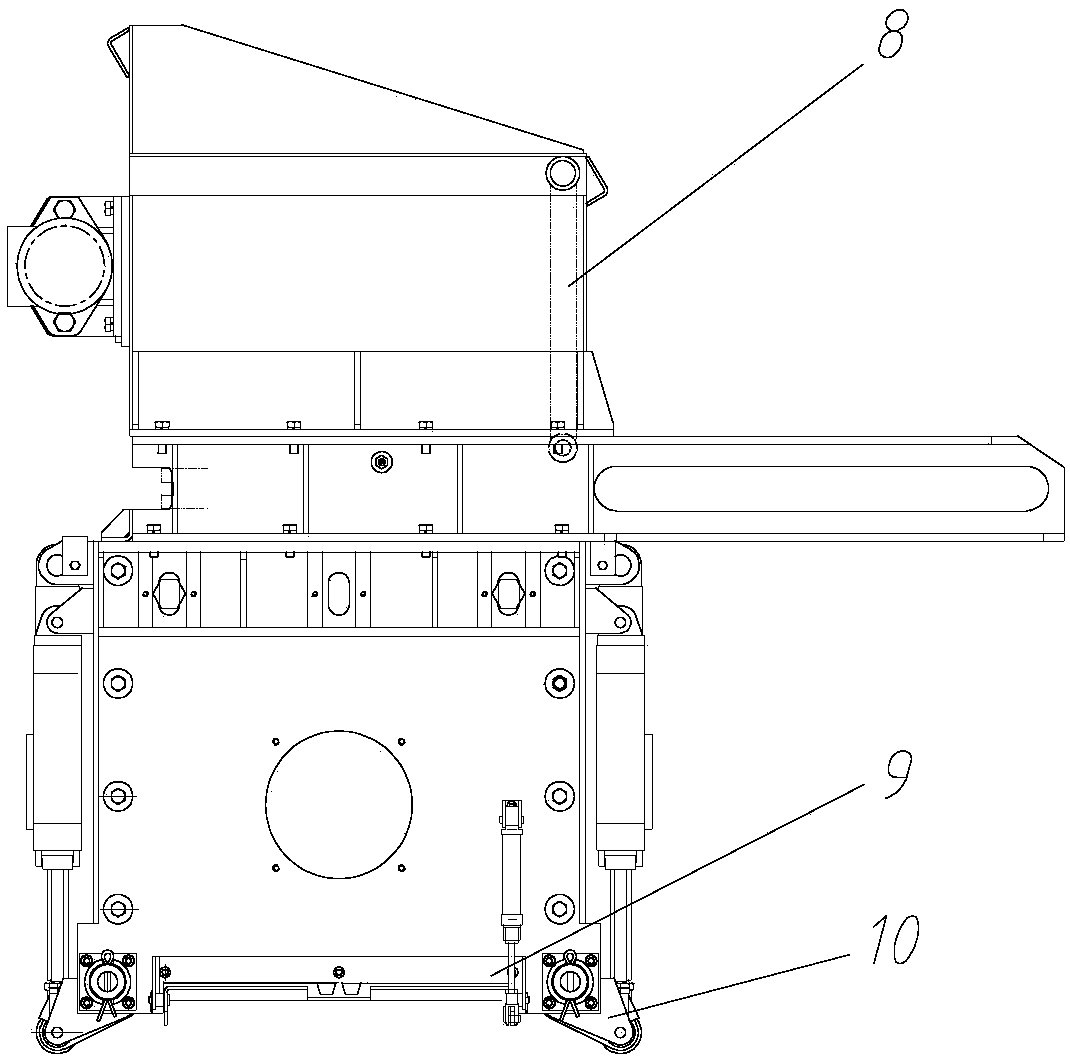

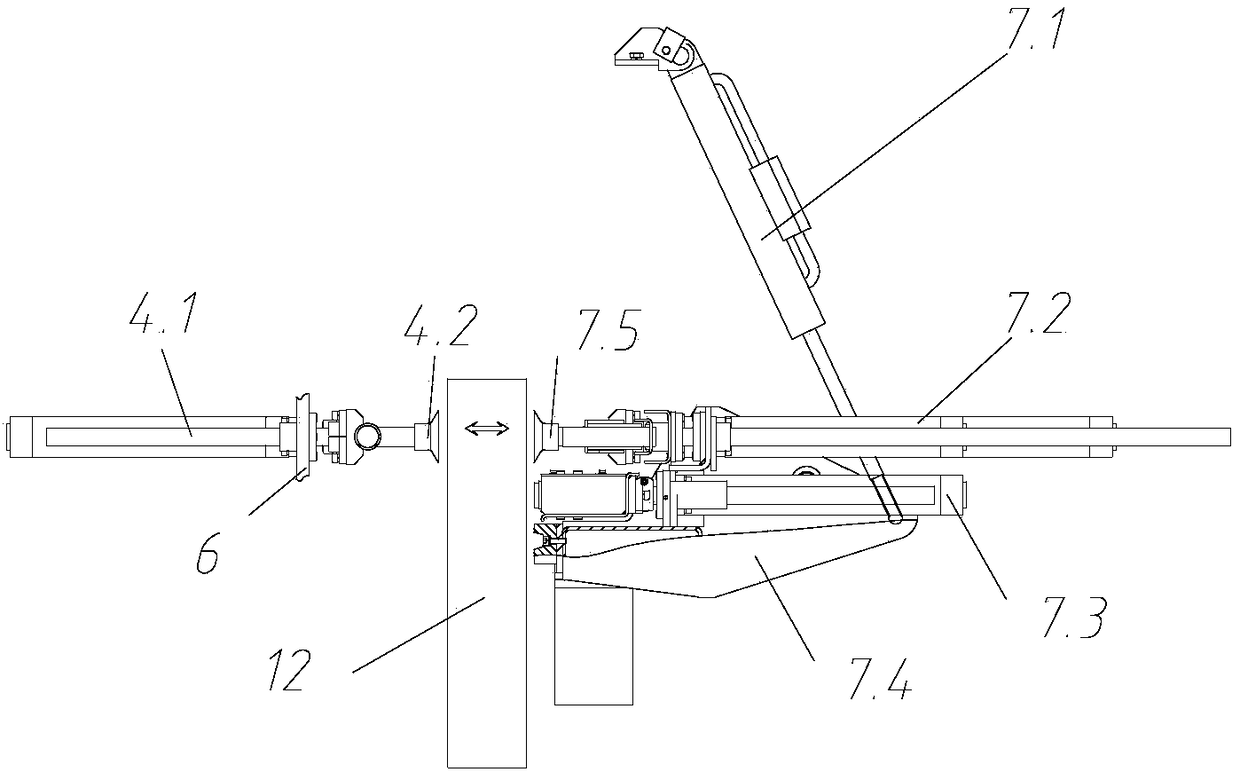

[0035] A vehicle-mounted automatic packaging mechanism for membranes, such as figure 1 and figure 2 As shown, the hopper assembly 1 is installed above the frame 6, the swing rod 8 is installed above the interior of the hopper assembly 1, the front and rear bag support plates 9, left and right bag expansion plates and supporting plates 10 are located at the bottom of the hopper assembly 1, and the continuous film is conveyed from above Entering the inside of the hopper assembly 1, the swing rod 8 swings back and forth periodically, so that the film body is laid on the supporting plate 10; at the same time, the flipping bag taking assembly 7 is flipped to a vertical position under the drive of the flip cylinder, and the cylinder drives the suction cup to the bag pool for adsorption Packing bag 12, turn over the oil cylinder to retract, and the packing bag is located directly below the hopper at this time, the air cylinder in the bag opening component 4 drives the suction cup to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com