Automatic collecting device for residual die films

A technology of automatic collection and collection device, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of high labor management cost and difficult management, and achieve the elimination of the risk of scalding, the reduction of personnel management costs, and the reduction of personnel management operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

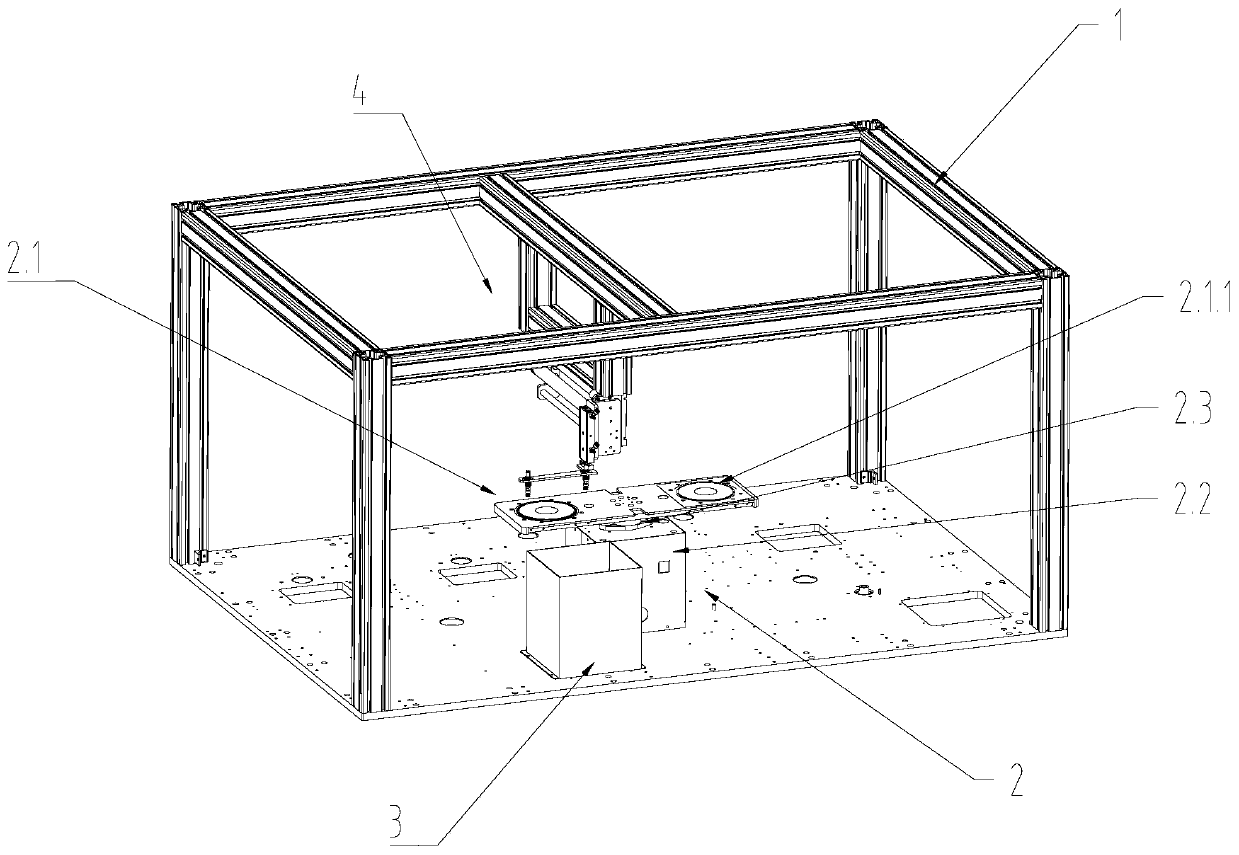

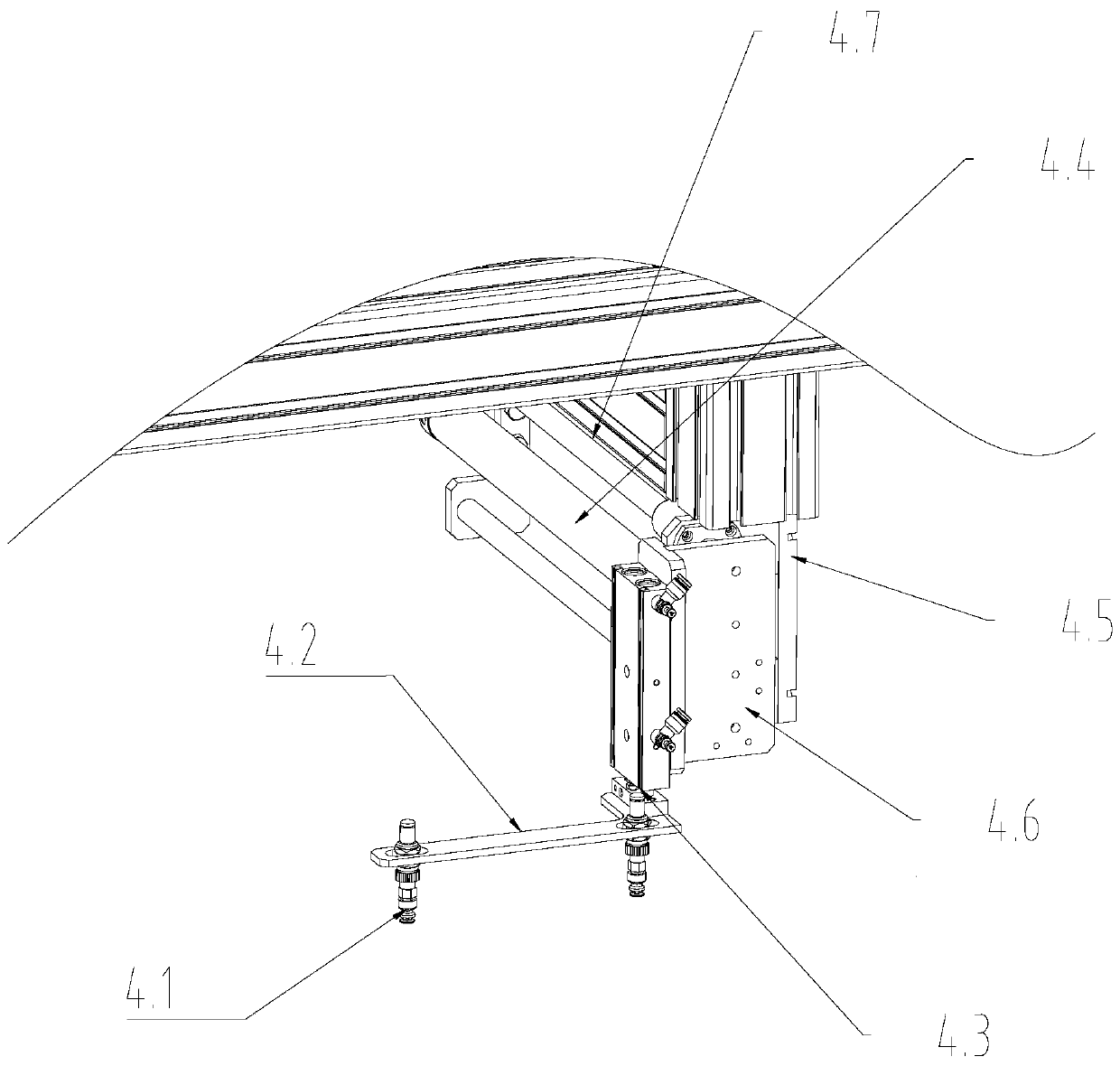

[0019] A kind of crystal film residual film automatic collection device, such as figure 1 As shown, including a frame 1, the inside of the frame 1 includes a crystal film stage mechanism 2 for placing the crystal film, a crystal film residual film collecting device 3 for collecting the crystal film residual film, and a crystal film residual film collection device 3 for picking up the crystal film residual film. The crystal film residual film pick-and-place mechanism 4 of the film. The crystal film stage mechanism 2 includes a crystal film stage 2.1 provided with an operating station and a crystal film stage driving device 2.2 for driving the crystal film stage to rotate. There are at least two operating stations 2.1.1 in the wafer carrier 2.1. In this embodiment, the crystal film carrier 2.1 has a flat structure, and there are two operating stations in the crystal film carrier, and the two operating stations 2.1.1 are located on the left and right sides of the flat crystal fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com