Spring supporting rod

A technology of support rods and spring barrels, applied in the direction of springs, springs/shock absorbers, shock absorbers, etc., can solve problems such as seal ring failure, and achieve the effect of avoiding bump damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

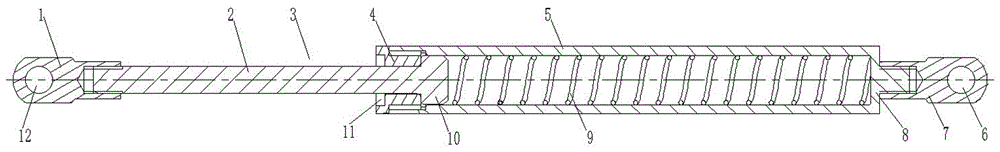

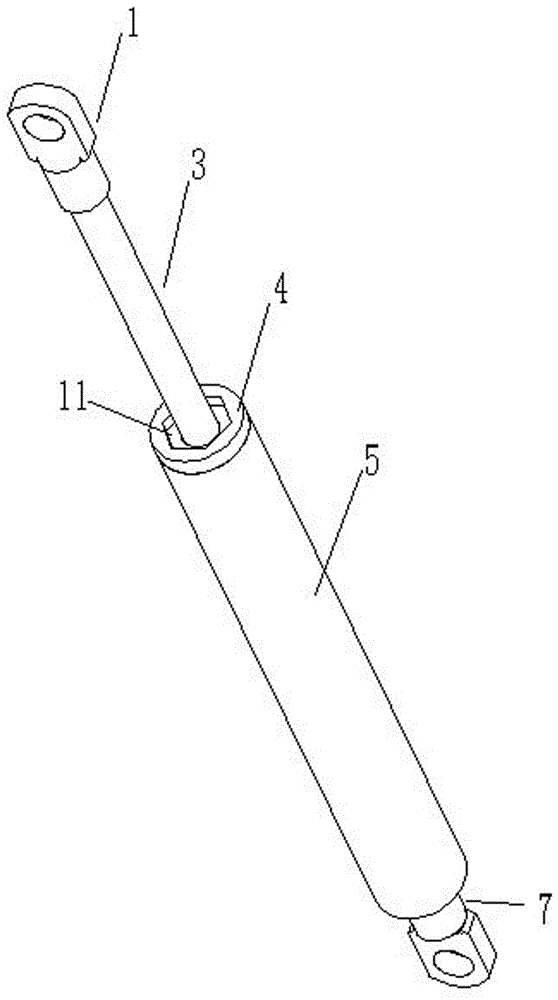

[0016] Examples of spring struts are Figure 1~2 As shown: the spring support rod includes a spring tube and a support rod 3, the spring tube includes a cylinder body 5 whose axis extends in the front-to-back direction, the front end of the inner hole of the cylinder body 5 is a threaded section, and a nut 4 is screwed on the threaded section, An inner square hole structure 11 for torque input is arranged coaxially on the front end face of the nut. The rear end of the cylinder body 5 is integrally provided with a cylinder bottom 8, on which the spring cylinder connecting ear 7 is screw-mounted, the spring cylinder connecting ear 7 is provided with a spring cylinder hinge hole 6, the spring cylinder connecting ear 7 and the spring cylinder hinge hole 6 constitutes the connection structure for connecting the spring tube to the spring tube on the first component. The support rod is a stepped shaft structure, and the support rod includes a large-diameter section 10 assembled in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com