Closed hole punching method of GH99 alloy high cylindrical ring part

A GH99 and alloy technology, applied in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., to achieve the effect of improving consistency, dimensional accuracy and batch stability, and reducing operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] The main chemical element content (percentage by weight) of the GH99 alloy is: C content≤0.08%, Cr content 17.0%~20.0%, Co content 5.0%~8.0%, W content 5.0%~7.0%, Mo content 3.5%-4.5% Al content, 1.7%-2.4% Al content, 1.0%-1.5% Ti content, Fe content≤2.0%, B content≤0.005%, Ce content≤0.02%, Mg content≤ 0.01%, containing Mn ≤ 0.4%, containing Si ≤ 0.5%, containing P ≤ 0.015%, containing S ≤ 0.015%, and the balance being Ni.

[0016] The steps of this method are as follows:

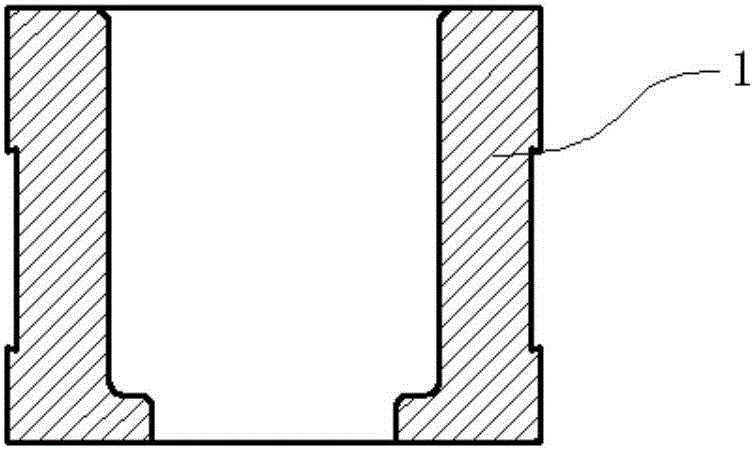

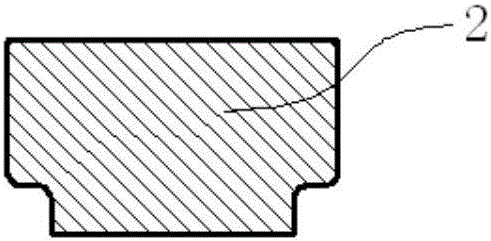

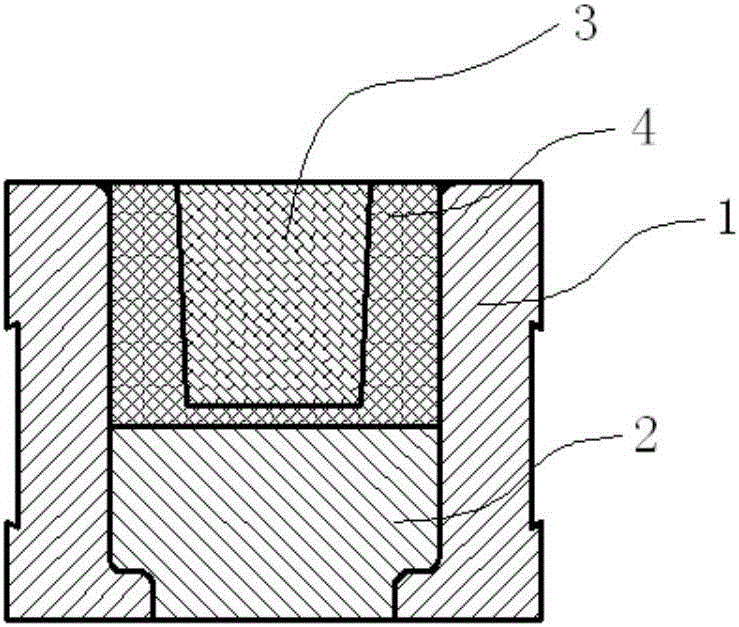

[0017] Cut the GH99 alloy into bars according to certain specifications; heat the GH99 alloy bars to 1130±10°C for heat preservation, and the furnace temperature is ≤700°C; after heating through, put the GH99 alloy bars on the press to drive the forging hammer Upsetting the GH99 alloy rod to a predetermined size; put the upset GH99 alloy billet 4 into the punching die 1, and put them together under the press. The outer wall of the punching die 1 has a dovetail groove for fixing. Prevent the punchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com