Rotational-torsion-varying double-shaft synchronous rotation shaft apparatus

A shaft device and torsion technology, which is applied in pivot connection, instrument, calculation, etc., can solve problems such as single function, inability to achieve synchronization, and limit the thin development of electronic equipment such as notebooks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention.

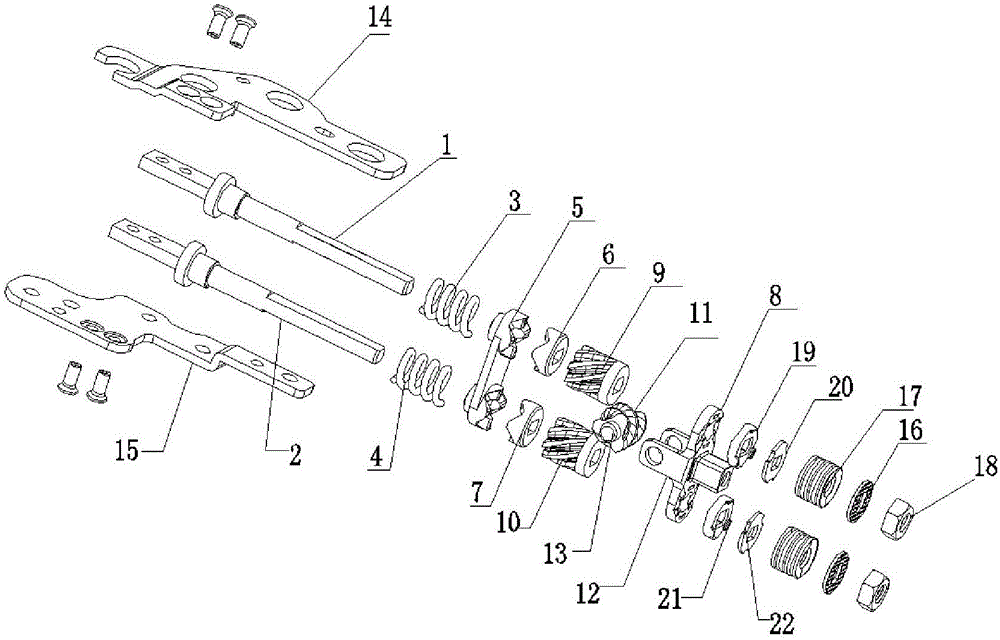

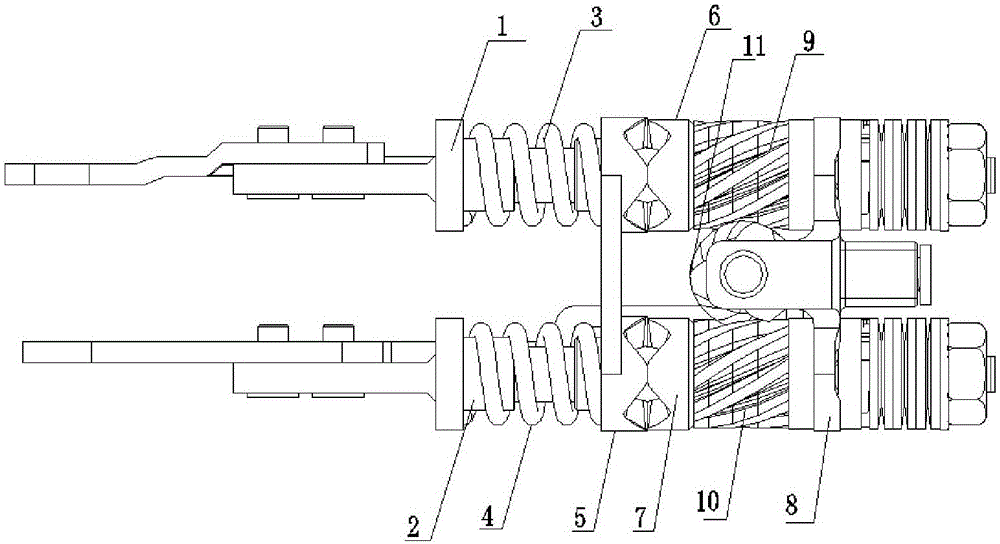

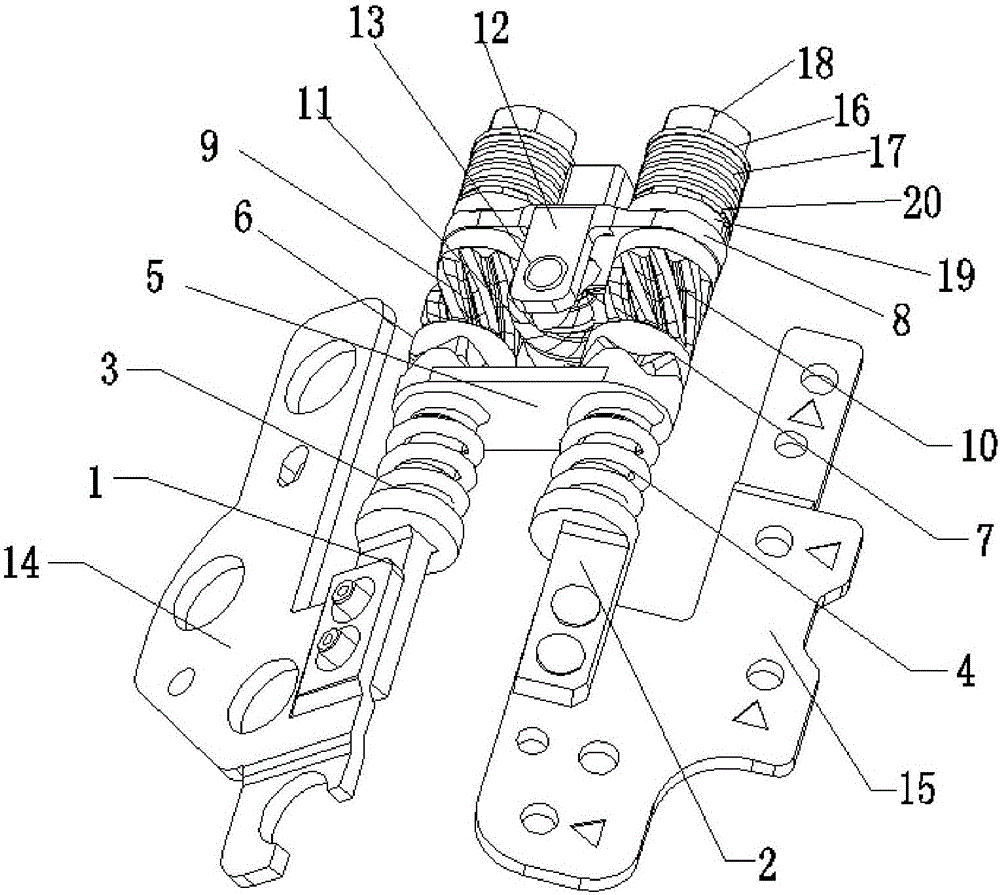

[0031] Such as figure 1 , figure 2 and image 3 As shown, a dual-axis co-moving rotating shaft device with variable rotational torque includes a first shaft core 1, a second shaft core 2, a rotational torque changing mechanism, a first shaft torque component, a second shaft torque component and a The first shaft core and the second shaft core move together, and the rotation torque changing mechanism includes a first elastic body 3, a second elastic body 4, a transmission connecting plate 5, a first transmission body 6 and a second Transmission body 7; the first transmission body is sleeved on the first shaft core, and the second transmission body is sleeved on the second shaft core; the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com