Multifunctional straw hot water heating and cooking furnace

A multi-functional, hot water technology, applied in heating stoves and cooking fields, can solve the problems of waste, insufficient utilization of abundant crop stalks, increased heating expenses, etc., to achieve convenient production, saving living expenses, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

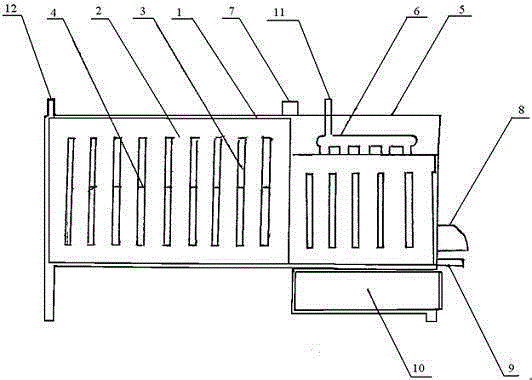

[0011] Such as figure 1 As shown, a multifunctional straw hot water heating and cooking stove includes a furnace body provided with an iron furnace body shell 1, a furnace chamber and an up and down rotary flue 3 formed by flue partitions 4 at intervals.

[0012] Furnace body is provided with flue mouth 7, and this flue mouth 7 and rotary flue 3; A heating hot water bag 2 composed of a radiator; a pot mouth 5 is set in the center of the upper part of the furnace body, a firewood filling port 8 and a water inlet 9 are arranged on the front side of the front end, and an ash box 10 is arranged at the bottom; one end of the water inlet 9 It is connected with the running water pipe, and its other end is connected with the radiator in the washing hot water bag 6 and the heating water bag 2 respectively; the washing hot water bag 6 is provided with a washing hot water outlet pipe 11, and the washing hot water outlet pipe 11 is connected There is a hot water storage tank; the heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com