Manufacturing process of shell with optical heart rate inductive sensor and shell

A technology of inductive sensor and manufacturing process, applied in applications, other home appliances, home appliances, etc., can solve the problems of increasing living costs, single shell structure, rarely having a barrier function, etc., to achieve the effect of saving living expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

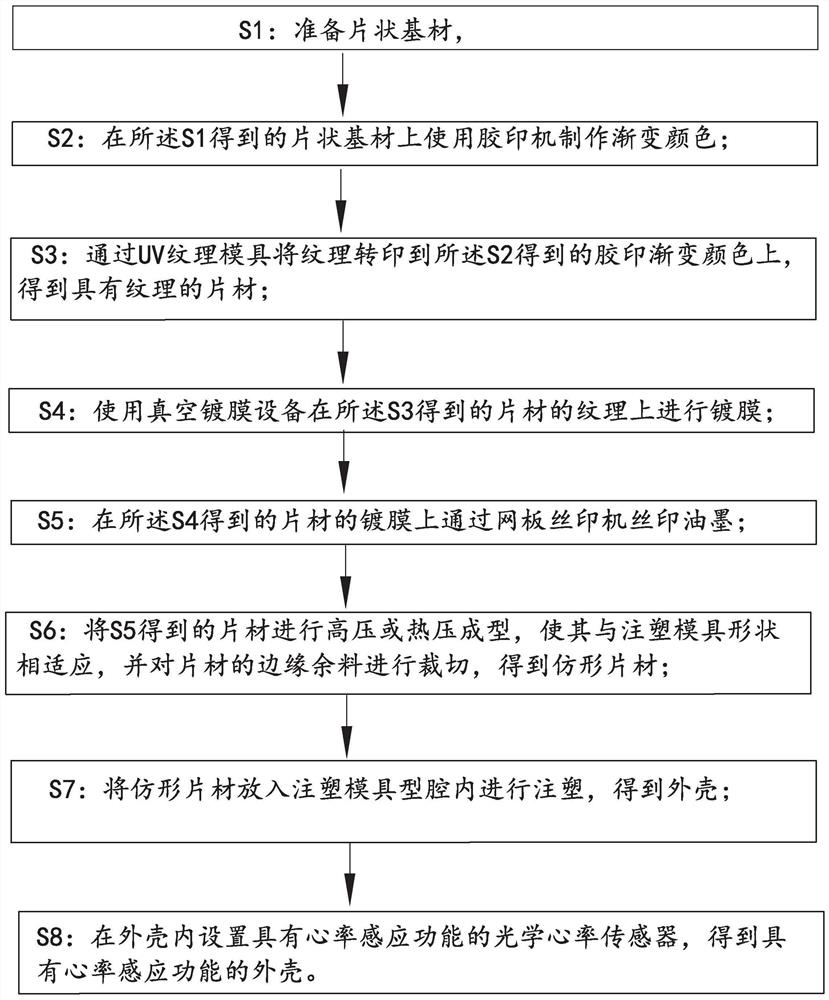

[0028] This embodiment provides a manufacturing process for a housing with an optical heart rate sensing sensor, such as figure 1 shown, including the following steps:

[0029] S1, preparing a sheet substrate; the substrate is made of a mixture of PMMA+PC; PMMA refers to polymethyl methacrylate, and PC refers to polycarbonate.

[0030] S2, using an offset printing machine to make gradient colors on the sheet substrate obtained in S1; the specific process is, step a, using the existing process to make a CTP plate, and output full-page or partial dots; step b, for printing ink Adjust the ratio and add additives in proportion. The additive is varnish, accounting for 20%-60%. With the help of the two laws of oil-water immiscibility and selective adsorption of the printing plate, the ink and water are on the printing plate Keep mutual balance to realize dot transfer, and thus achieve the effect of brightening and anti-reflection of printed images.

[0031] S3, transfer the textur...

Embodiment 2

[0041] Compared with Example 1, S1, S2, S4, S7, S8 are completely consistent, the difference is:

[0042] S3, transfer the texture to the offset gradient color obtained in S2 through the UV texture mold to obtain a textured sheet; the specific process is to pour the UV glue on the textured mold, put the material, and use a roller The press uniformly coats a layer of UV glue on the entire surface of the UV texture, and uses an LED light with a main spectrum of 350nm for exposure. After 3 seconds of exposure and curing, the material is torn off, and the UV glue texture is transferred to the sheet.

[0043] In this step, the material is polyethylene terephthalate (PET). Texture rendering material is UV glue (acrylate).

[0044] S5, on the coated film of the sheet material obtained in said S4, use a screen printing machine to screen ink; the specific process is to use a 300 mesh screen to carry out ink screen printing on the coated surface, and each screen printing needs to be bake...

Embodiment 3

[0048] Compared with Example 1, S1, S2, S4, S7, S8 are completely consistent, the difference is:

[0049] S3, transfer the texture to the offset gradient color obtained in S2 through the UV texture mold to obtain a textured sheet; the specific process is to pour the UV glue on the textured mold, put the material, and use a roller The press uniformly coats a layer of UV glue on the entire surface of the UV texture, and uses an LED light with a main spectrum of 350nm for exposure. After 5 seconds of exposure and curing, the material is torn off, and the UV glue texture is transferred to the sheet.

[0050] In this step, the material is polymethyl methacrylate (PMMA). Texture rendering material is UV glue (acrylate).

[0051] S5, on the coated film of the sheet material obtained in said S4, use a screen printing machine to screen ink; the specific process is to use a 600-mesh screen to carry out ink screen printing on the coated surface, and each screen printing needs to be bake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com