Method and module of optically detecting cup bottom

An inspection method and a detection module technology, which are applied in the field of inspection methods and modules for optical detection cup bottoms, and achieve the effects of quick and easy inspection, low cost, and safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation methods, The method, steps, structure, features and effects thereof are described in detail below.

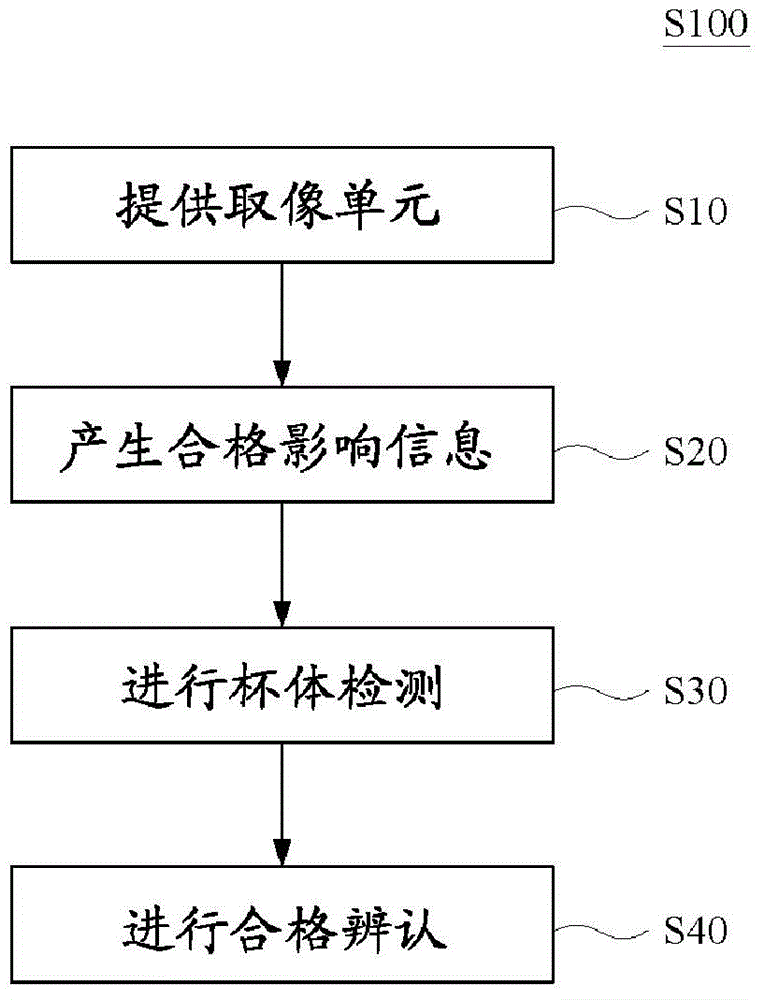

[0062] see figure 1 Shown is a flow chart of the steps of an inspection method for optically detecting the bottom of a cup according to an embodiment of the present invention. An optical detection cup bottom inspection method S100 of the present embodiment includes the following steps: providing an imaging unit (step S10), generating qualified image information (step S20), performing cup body detection (step S30) and performing qualified Identification (step S40).

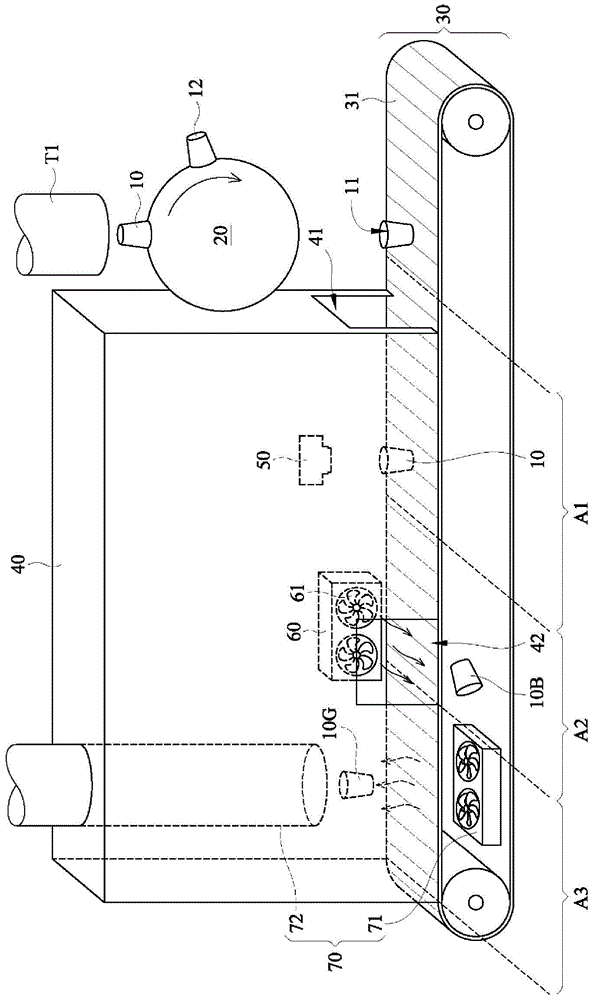

[0063] see figure 1 and Figure 3A to Figure 3C as shown, Figure 3A It is a three-dimensional schematic diagram of a device for optically detecting the inspection method of the bottom of the cup according to an embodiment of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com