A 3D folding printer

A printer and 3D technology, applied in 3D object support structures, metal processing equipment, manufacturing tools, etc., can solve problems such as rough wiring of printers, electrostatic interference, and interference with workbenches, so as to increase the overall aesthetics and reduce the three-dimensional space , the effect of solid structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in combination with specific embodiments.

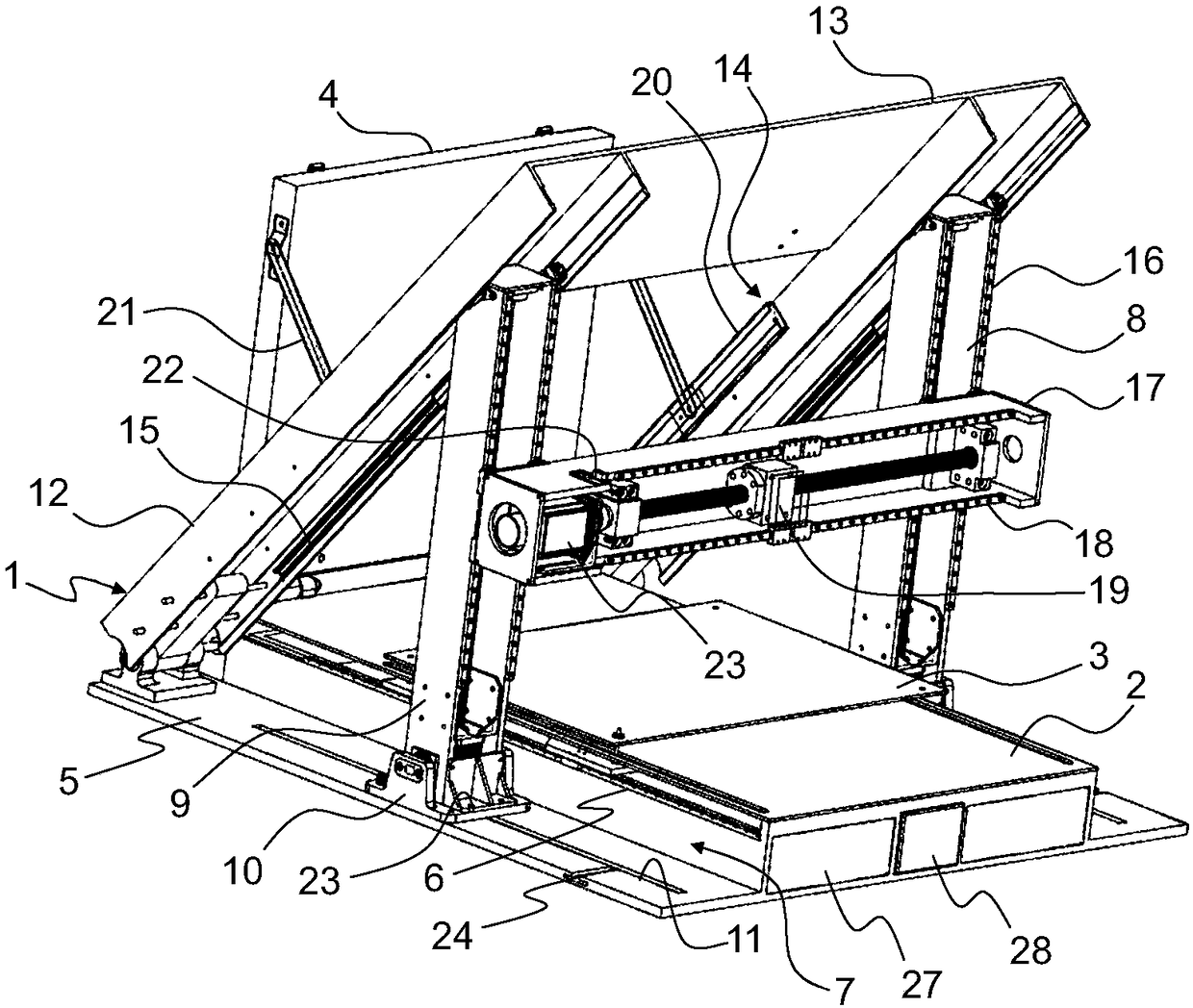

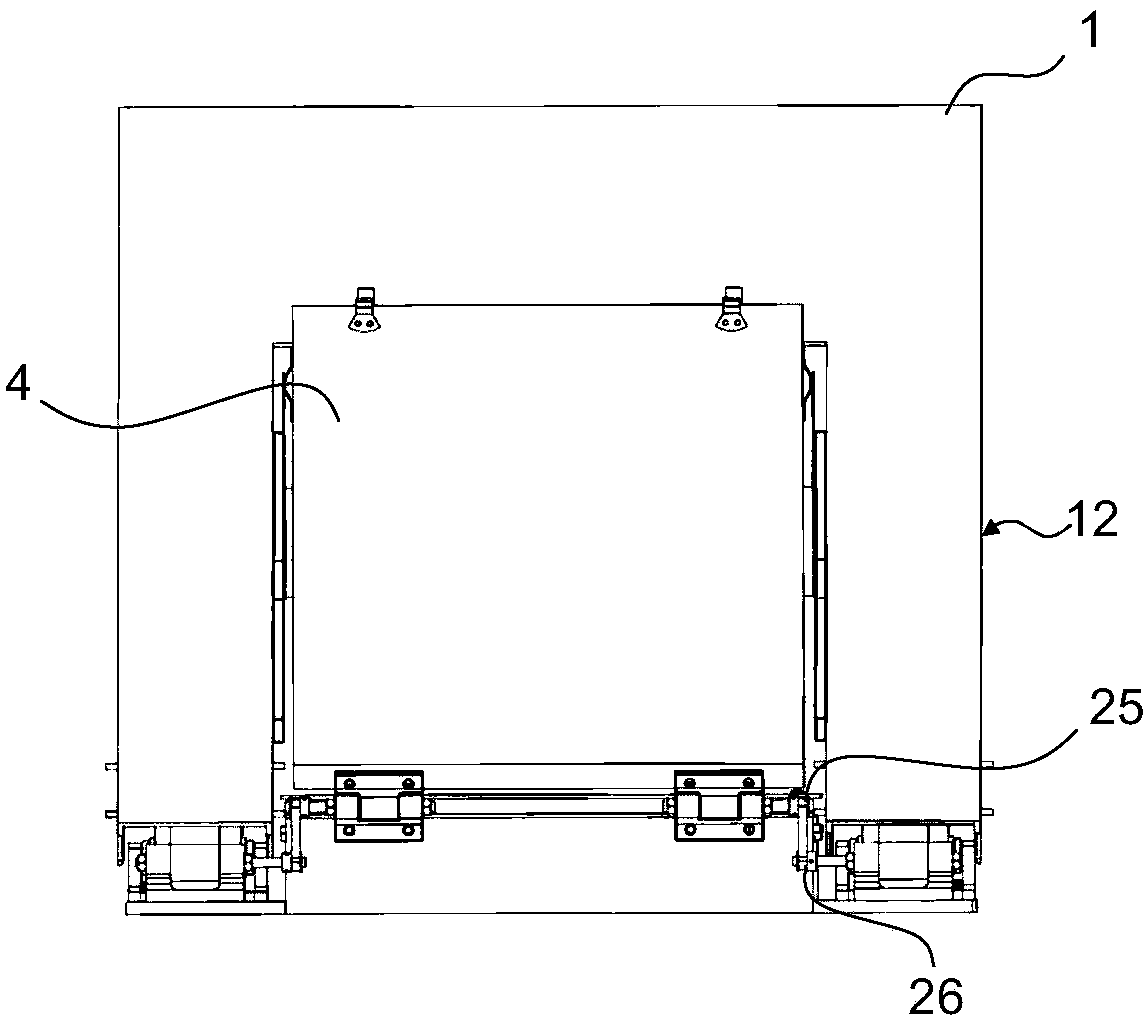

[0024] Such as figure 1 , figure 2 As shown, a 3D folding printer includes an upper cover 1, a base 2, a workbench 3, a main board 4 and a lower cover 5, the base 2 is located in the middle of the lower cover 5, the inner side of the base 2 is hinged with a main board 4, and the base 2 There is a first slide rail 6 extending along the X-axis direction, the first slide rail 6 is connected with the worktable 3 on the surface of the base 2, and the precise control between the workbench 3 and the base 2 is realized through motor and screw drive.

[0025] Both sides of the base 2 form a group of semi-open first accommodation spaces 7 on the lower cover plate 5, and a column 8 is respectively arranged on both sides of the base 2. The column 8 includes a hinged column 9 and a sliding seat 10, and the sliding seat is located on In the chute 11 of lower cover plate 5 surfaces, lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com