Full-hydraulic ABS braking system based on hybrid power and braking method thereof

A braking system and hybrid technology, applied in the ABS control system, electric braking system, braking control system, etc., can solve the problems of slow response time, inability to achieve braking pressure, and the influence of brake response time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0090] In this article, if there is no special explanation, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication. Labels with subscripts and non-subscripts indicate the same label, such as k2 and k 2 represent the same token.

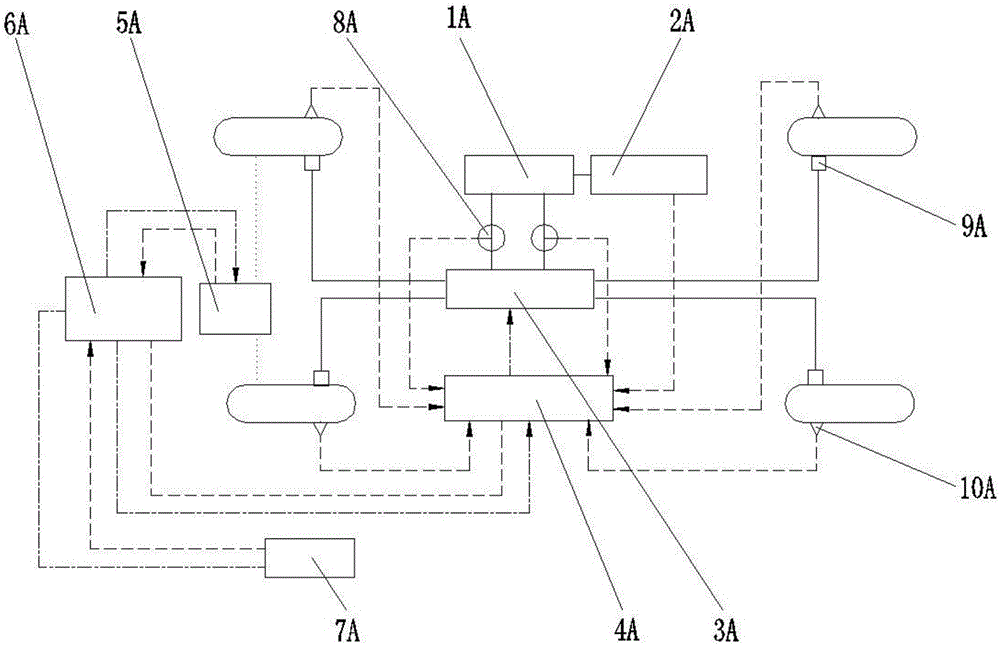

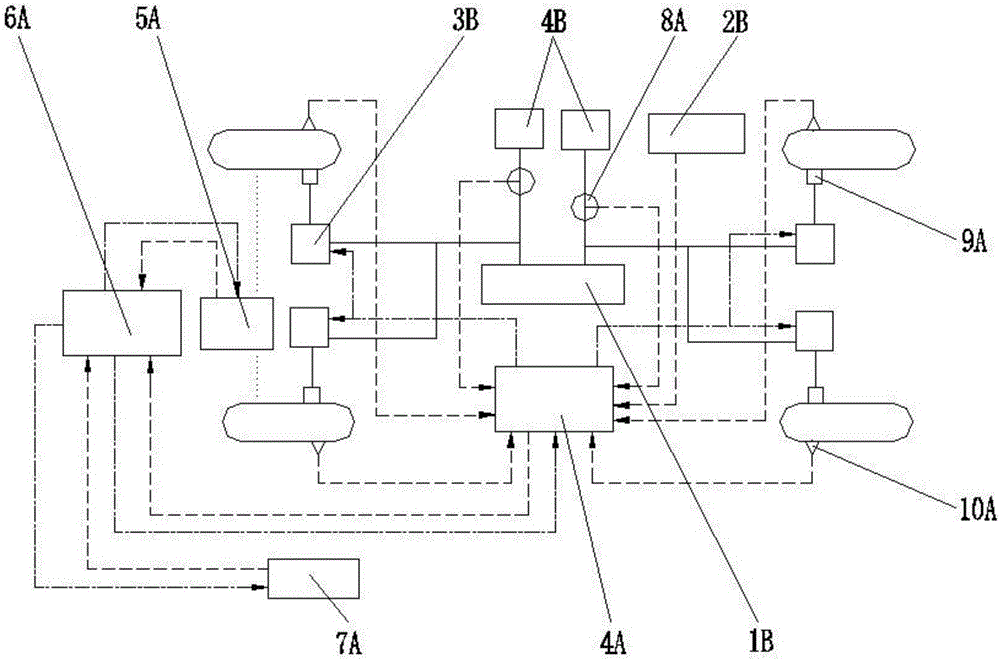

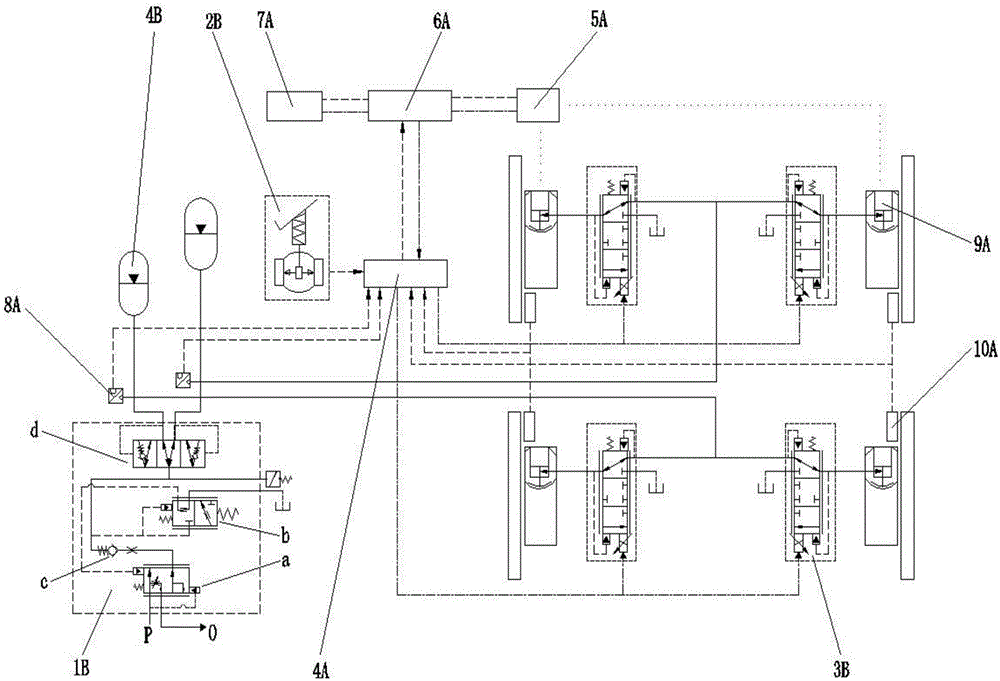

[0091] In order to solve the problems of the prior art, the present invention provides a full hydraulic ABS braking system based on hybrid power, which includes an accumulator 4B, a filling valve 1B, an electronic pedal 2B, a proportional valve 3B, and a brake controller 4A, the accumulator 4B is connected to the filling valve 1B through a pipeline, and a pressure sensor 8A is arranged on the pipeline, and the proportional valve 3B is connected to the pipeline between the accumulator 4B and the filling valve 1B. The electronic pedal 2B is connected to a brake controller 4A, and the brak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com