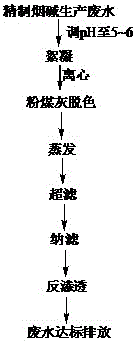

Nicotine production waste water flocculating decolorizaiton and evaporation membrane treatment technology

A technology for the production of wastewater and evaporation membranes, which is applied in the fields of filtration treatment, water/sewage treatment, natural water treatment, etc., to achieve the effect of reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Take 1000 mL of refined nicotine production wastewater (COD is 36000 mg / L, pH=9), add sulfuric acid solution to adjust the pH to 5, then add 2 mL of 10% polyaluminum sulfate, stir rapidly for 50 seconds, then slowly stir After 2 minutes, static decolorization and flocculation for 30 minutes and then filtration, the COD was 21000 mg / L.

[0020] 2. After the filtrate passes through the activated fly ash column, the COD is 13000 mg / L.

[0021] 3. The column liquid is evaporated and concentrated, and the COD of the evaporated liquid is 5700 mg / L.

[0022] 4. After the evaporated liquid passes through the ultrafiltration device, when the concentration ratio of the permeate to the concentrate is 8:1, the COD of the wastewater permeate reaches 414 mg / L (COD removal rate is 73%); after nanofiltration After treatment, when the concentration ratio is 10:1, the COD of the wastewater permeate drops to 119 mg / L; finally, after passing through the reverse osmosis device, when the...

Embodiment 2

[0024] 1. Take 1000 mL of refined nicotine production wastewater (COD is 48000 mg / L, pH=11), add sulfuric acid solution to adjust the pH to 5, then add 2 mL of 10% polyaluminum sulfate, stir rapidly for 50 seconds, then slowly stir After 2 minutes, static decolorization and flocculation for 30 minutes and then filtration, the COD was 29860 mg / L.

[0025] 2. After the filtrate passes through the activated fly ash column, the COD is 23000 mg / L.

[0026] 3. The column liquid is evaporated and concentrated, and the COD of the distilled liquid is 6500 mg / L.

[0027] 4. After the evaporating liquid passes through the ultrafiltration device, when the concentration ratio of the permeate and the concentrate is 8:1, the COD of the wastewater permeate reaches 876 mg / L; after nanofiltration treatment, when the concentration ratio is 10 :1, the COD of the wastewater permeate drops to 253 mg / L. Finally, after passing through the reverse osmosis device, in the case of a concentration ratio ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap