Suspension rail type slurry extracting and levelling machine

A technology of leveling machine and suspension rail, which is applied to bridge parts, erecting/assembling bridges, bridges, etc., can solve the problems of flatness and waterproof performance, difficult to guarantee flatness, poor integrity of concrete, etc., to improve construction quality, Avoid secondary seams and ensure the effect of stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

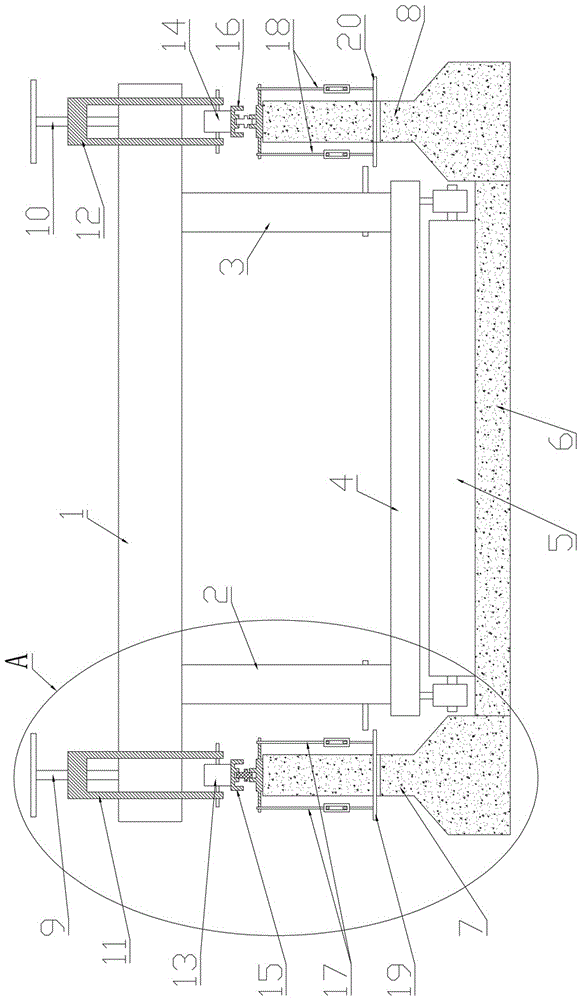

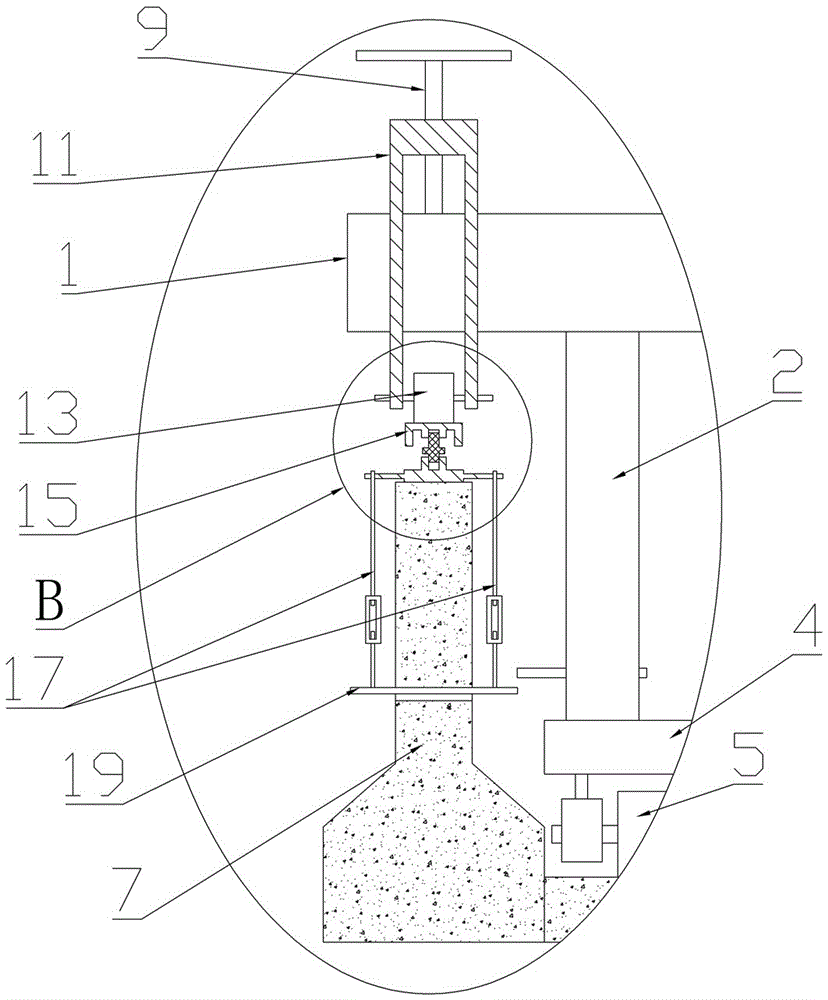

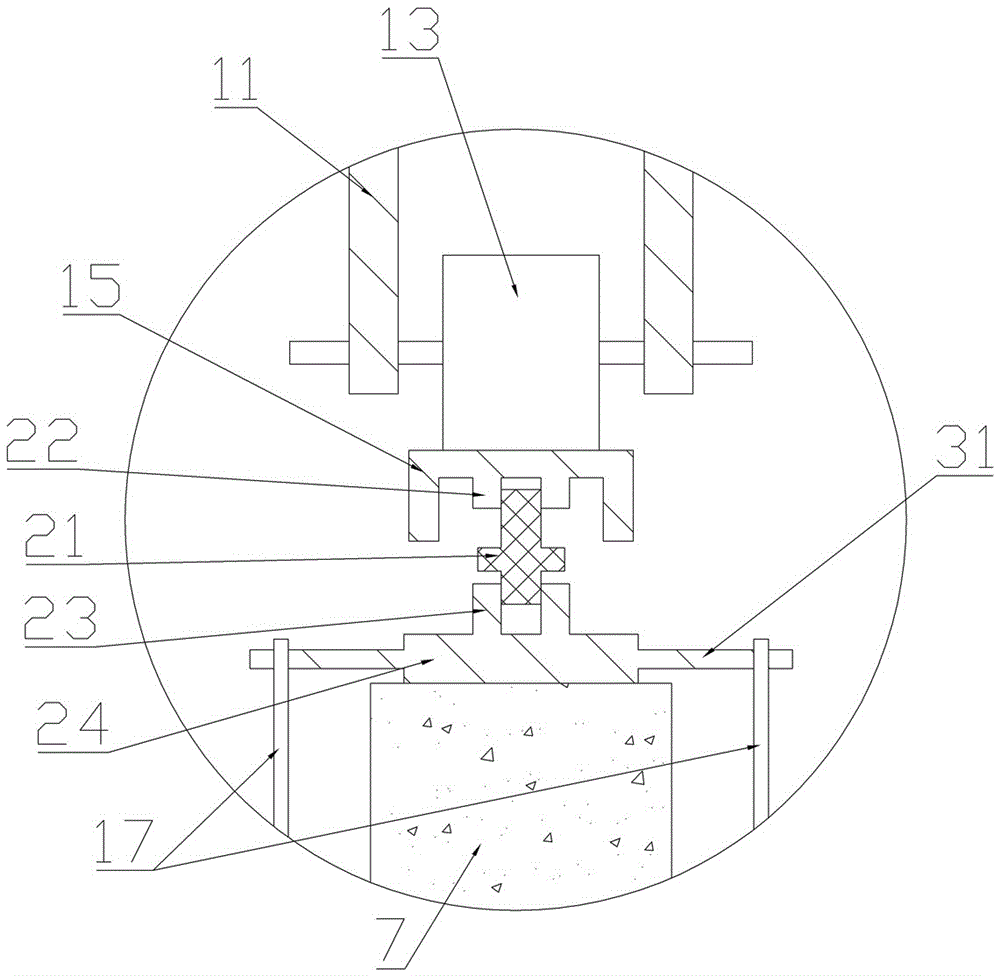

[0026] Embodiment 1: a kind of suspension rail type pulp leveling machine, see Figure 1 to Figure 7 It comprises two parallel tracks 15,16 laid on the anti-collision guardrails 7,8 on both sides of the bridge plate 6, a suspension mechanism that is arranged on the two tracks 15,16 and can slide on the tracks 15,16, Further, a fastening and leveling mechanism for fixing and leveling the rails 15 and 16 is also included.

[0027] In this embodiment, the fastening and leveling mechanism includes a fixing plate 24 arranged on the anti-collision barriers 7 and 8, a lower support pipe 23 arranged on the fixing plate 24 and internally provided with internal threads, On the lower surface of the rails 15, 16 that are arranged opposite to the lower support pipe 23, an upper support pipe 22 that is also provided with an internal thread is also provided inside, and an adjustment screw 21 is also included, and the upper end and the lower end of the adjustment screw 21 The screw threads o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com