Arc-shaped gas-water separator

A gas-water separator, arc-shaped technology, applied in degassed water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the difficulties of vertical drilling, insufficient space for electric drill operation, and guarantee of gas-water separation effect In order to achieve the effects of fast and thorough air bubble escape, low-cost operation of sewage treatment, and remarkable effect of gas-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

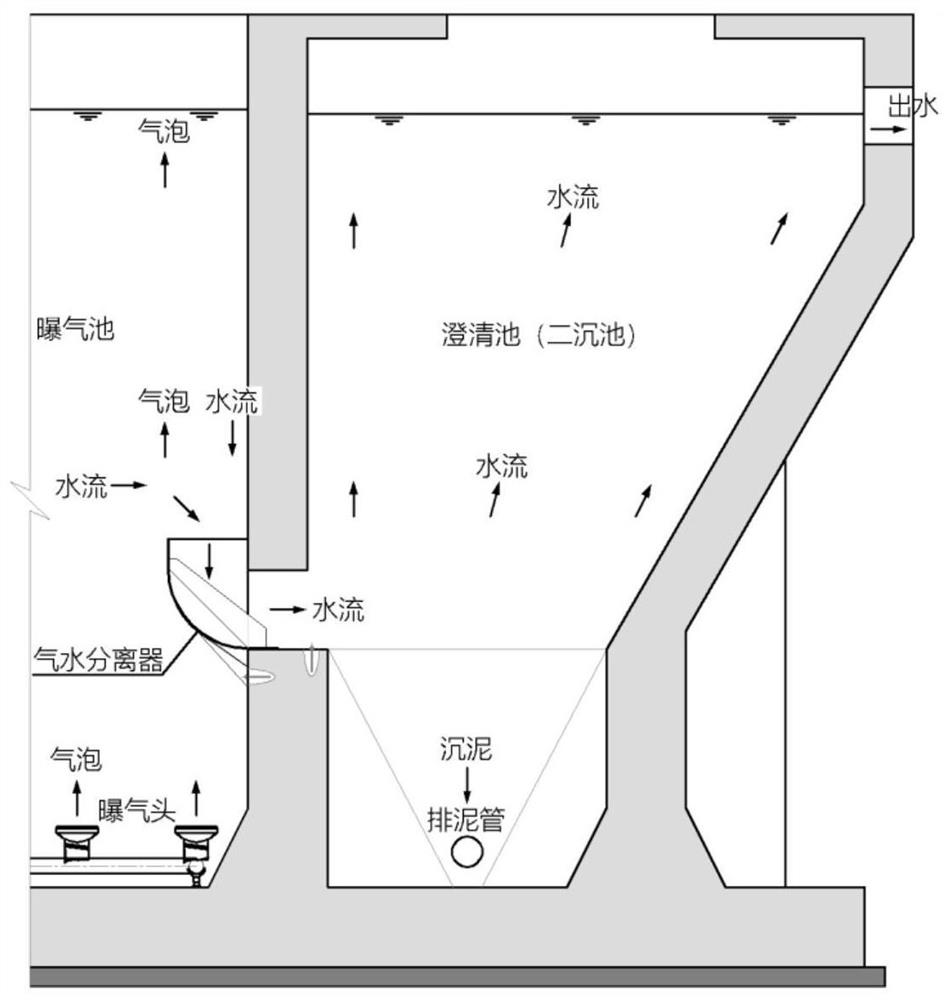

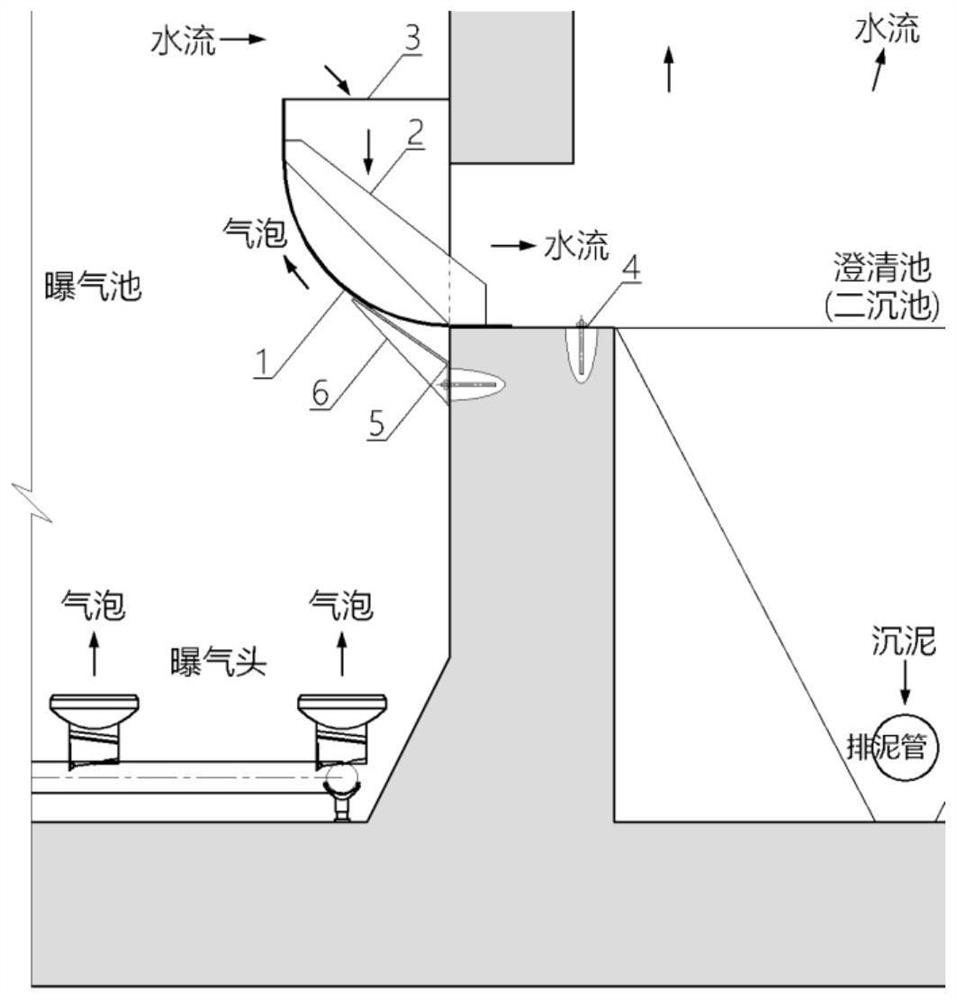

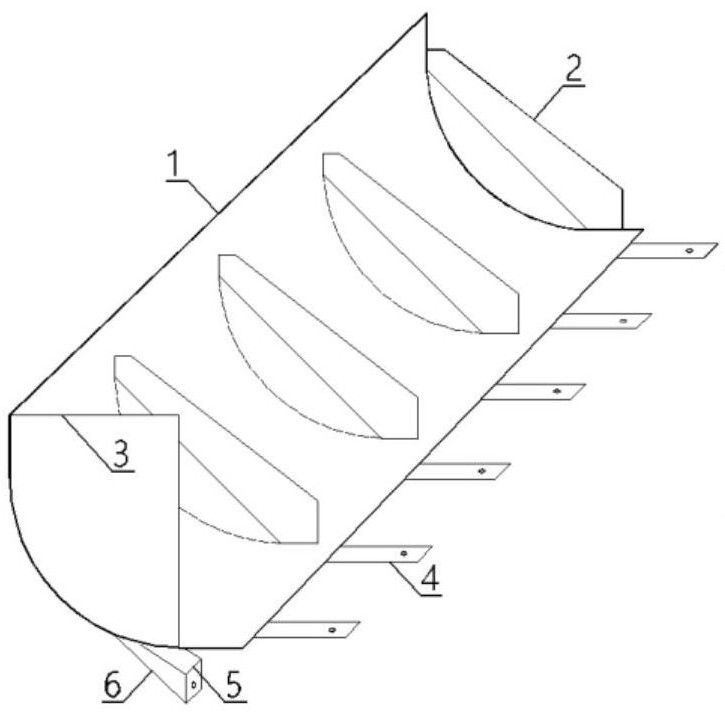

[0033] Please refer to the attached figure 1 , figure 2 , image 3 At the same time, in combination with a sewage treatment project in Nanyang City, Henan Province, an arc-shaped gas-water separator of the present invention is used as an embodiment to further describe the present invention in detail. Therefore, this embodiment provides a practical technical solution that has been successfully used.

[0034] It should be emphasized here that the description of the specific technical solutions of the embodiments is used to help understand the essence and intent of the present invention, and does not constitute a limitation of the present invention. In addition, in the following descriptions, descriptions of known technologies and familiar structures (such as lap welding, segmental manufacturing for vehicle transportation and bolting or welding on site, etc.) are omitted in order to avoid unnecessary confuse the concept of the present invention.

[0035] The sewage treatment...

Embodiment 2

[0051] Taking a township sewage treatment project in Qianjiang City, Hubei Province as an example of using an arc-shaped gas-water separator of the present invention, the present invention will be further described in detail. Therefore, this embodiment provides another practical and feasible technical solution that has been successfully used.

[0052] The sewage treatment scale of this embodiment is 1600m 3 / d, in order to facilitate non-stop production during pool or equipment maintenance, the design is divided into 2 grids of 800m each 3 / d integrated aeration and sedimentation tank, figure 1 Shows a single cell 800m 3 / d The schematic diagram of the rear end of the integrated tank, that is, the schematic diagram of the on-site assembly and use of the arc-shaped gas-water separator in this embodiment, the effective water depth of the aeration tank is 4.30m, and 4 arc-shaped gas-water separators are installed on 2 At each water-passing hole with a horizontal length of 4.02...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com