Expansive tail pipe drilling operation device and operation method thereof

An operating device and expansion technology, applied in drilling equipment and methods, drilling equipment, earthwork drilling and production, etc., to reduce the risk of drilling and expansion and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention will be further described now in conjunction with the accompanying drawings.

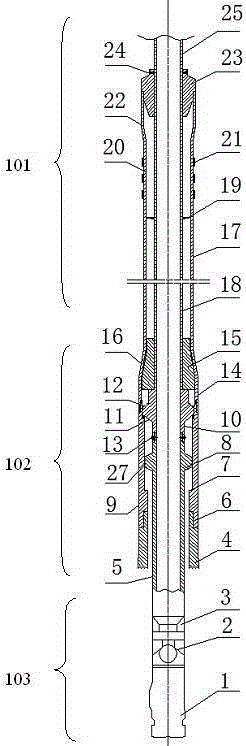

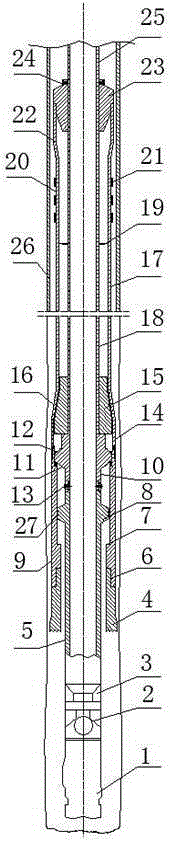

[0029] Such as figure 1 , figure 2 As shown, an expandable liner drilling operation device involved mainly includes three parts: a liner expansion assembly 101 , a liner connection and activation assembly 102 and a liner drilling assembly 103 .

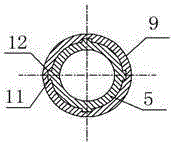

[0030] The liner drilling assembly 103 is an inner pipe drilling tool protruding from the bottom of the liner to realize the function of liner drilling. It includes a double-centered reaming drill bit 1, a floating hoop 2, a ball seat 3 and the lower part of the sealing central tube 5. The double-centered reaming drill bit 1 is an eccentric drill bit, which can realize the reaming operation while drilling, and is convenient for the liner to run in.

[0031] The liner connection and starting assembly 102 is a connection device between the liner and the drilling assembly, which realizes functions such as connection between the liner a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com