Mine fire abnormal area detection method based on directional drilling technique

A technology of directional drilling and detection methods, applied in directional drilling, fire prevention, mining equipment, etc., can solve problems such as drilling failure, inability to determine the location of the fire source area, and affecting fire prevention and extinguishing work, so as to save drilling workload, The effect of improving detection efficiency and increasing detection range

Active Publication Date: 2017-04-19

XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

View PDF14 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] (1) Conventional drilling adopts ordinary rotary drilling, the opening parameters are fixed, and the hole is a straight hole. If there are old lanes, small kilns and goafs between the target target area and the opening point, it will not be possible to pass through, resulting in drilling failure

[0006] (2) The conventional drilling trajectory is uncontrollable. Even if the designe

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

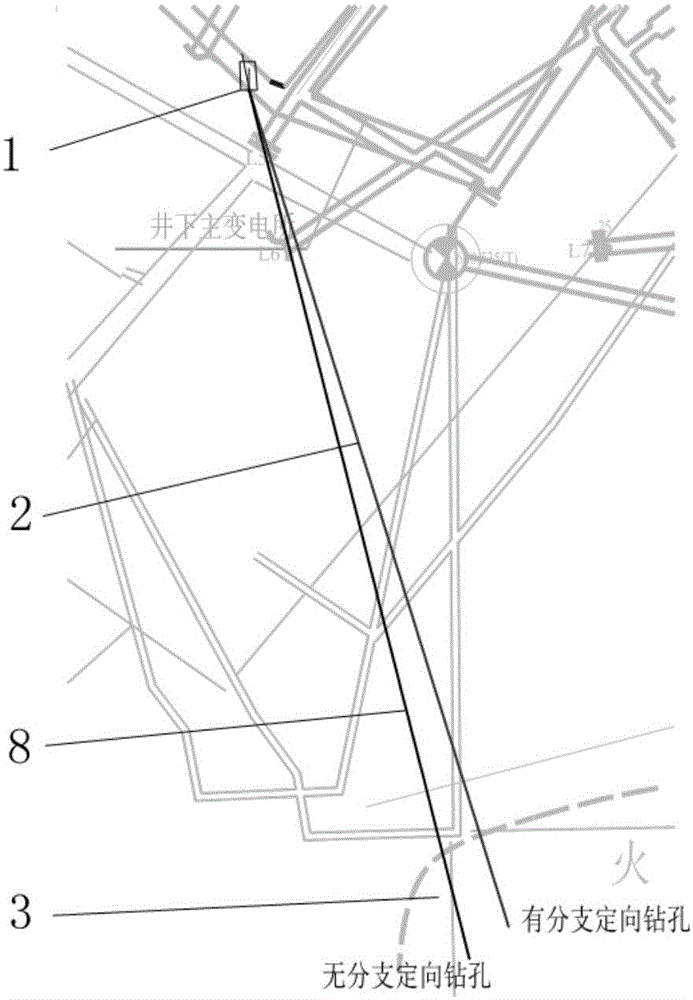

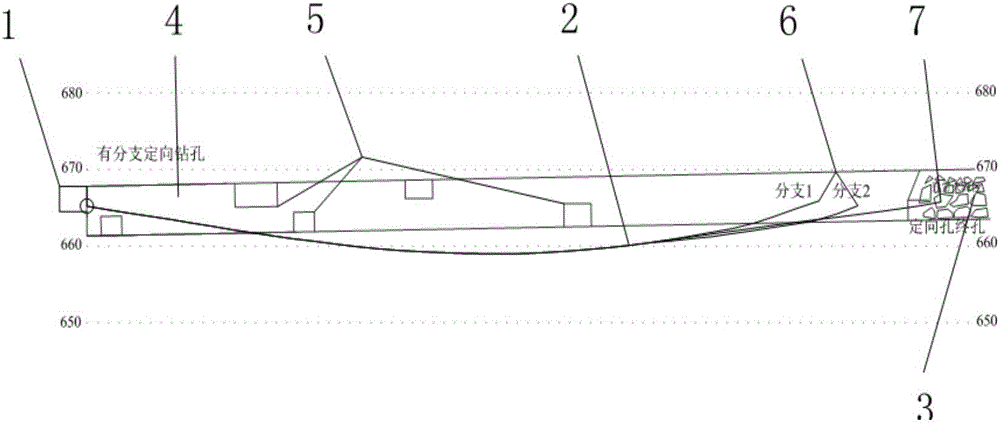

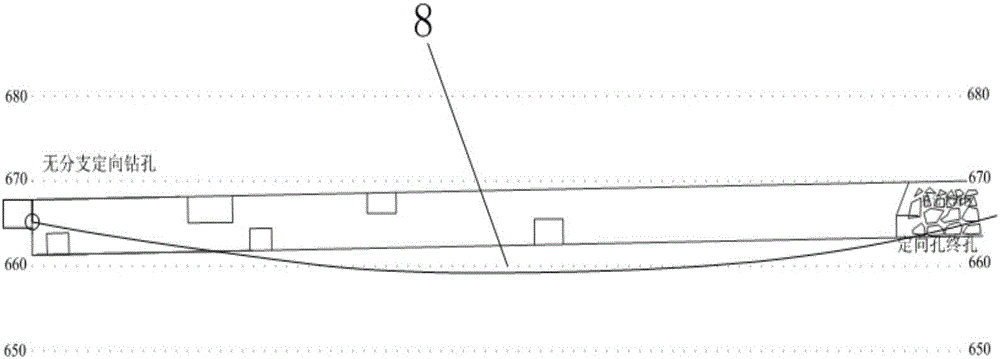

The invention belongs to the technical field of fire preventing and extinguishing under a coal mine, and relates to a mine fire abnormal area detection method based on a directional drilling technique. The detection method can achieve real-time measurement while drilling, the drilling can avoid excavation of used roadways by manually controlling the drilling track, the detection range is extended by adopting a directional drilling branching process, measurement guide wires and sensors are placed through a drilling tool during directional drilling, and detection on a fire abnormal area is completed. The method comprises the steps that the relative locations of small pits, the used roadways and goaves of the abnormal area are inferred according to the data, a detection drilling field is developed in the position close to the suspected fire abnormal area, drilling is implemented, and the detection work of the fire abnormal areas is completed.

Description

technical field [0001] The invention belongs to the technical field of underground fire prevention and extinguishing in coal mines, and relates to a method for detecting abnormal areas of mine fire sources based on directional drilling technology. Background technique [0002] my country is one of the countries with the most serious coal fires in the world. Coal spontaneous combustion affects social economy, loses coal resources, destroys the ecological environment, and brings a series of problems to human survival and safety. And with the continuous increase of coal mining scale, mining intensity and depth, the detection of hidden fire source anomalies in mine fire control has become the most difficult technical problem. [0003] The main means of coal ignition area detection is coal ignition temperature measurement. In terms of detection means, the detection channel is generally opened, that is, the temperature measurement borehole is constructed, and the temperature meas...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21F17/18E21F5/04E21B7/04E21B47/07

CPCE21B7/04E21B47/07E21F5/04E21F17/18

Inventor 段会军郝世俊赵永哲郑玉柱冯洁莫海涛胡振阳彭旭张强

Owner XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com