Optical athermalization design detection system and detection method

A detection system and optical technology, used in optical instrument testing, TV system components, measuring devices, etc., can solve problems such as labor-intensive, human-subjective influence, and high requirements for interpreters' professionalism and concentration. achieve high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

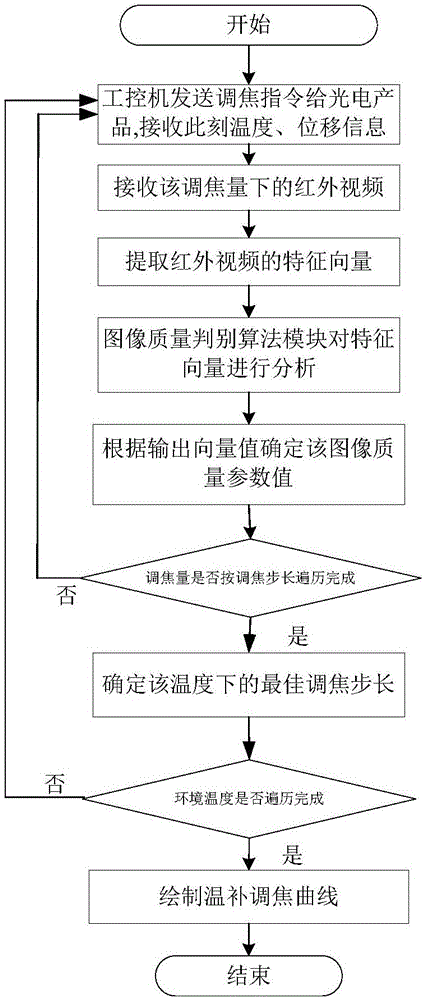

[0023] The purpose of the present invention is to provide an optical athermalization design detection system and detection method, which are used to detect and test the optimal focusing amount within the airborne ambient temperature range after the optical system is assembled into the optoelectronic product, through Temperature-compensated focusing test, using the image quality evaluation function to evaluate the image, find out the optimal focus curve under the airborne ambient temperature, and solidify the obtained temperature-compensated focusing curve inside the photoelectric product to realize the airborne ambient temperature. Athermalization design of the lower optical system.

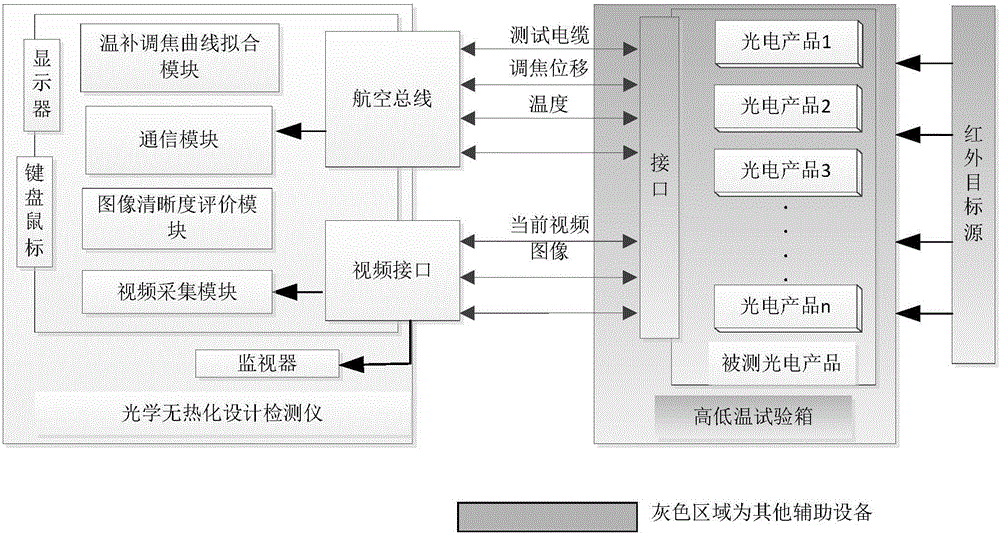

[0024] like figure 1 As shown, the optical athermal design detection system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com