Camera module base, camera module and electronic device

A technology of camera module and packaging seat, which is applied in the direction of TV, electrical components, color TV, etc. It can solve the problems of waste of optical filters, image stains, and difficulty in realization, and achieve the effects of height reduction, cost saving, and high imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

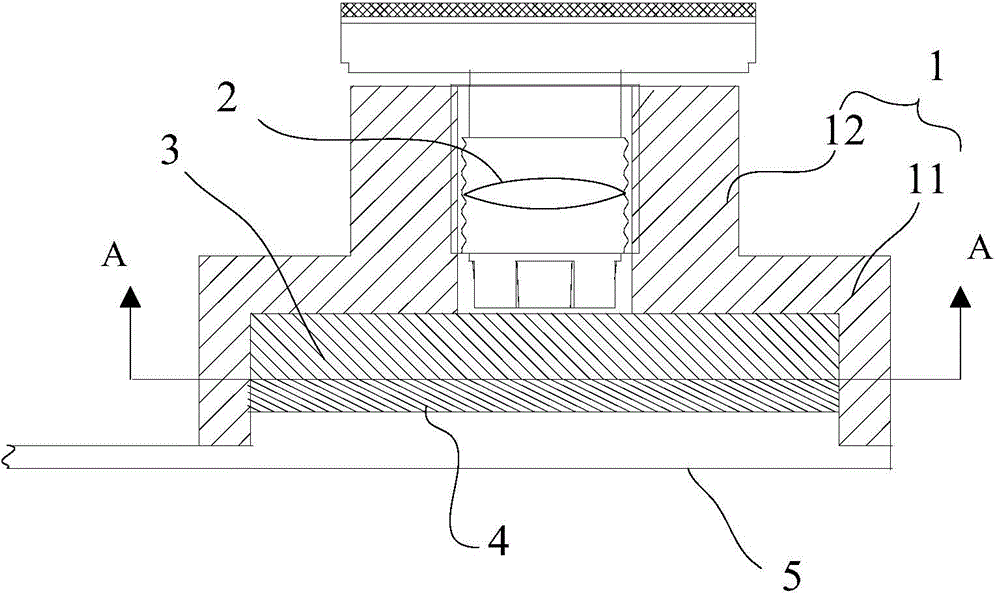

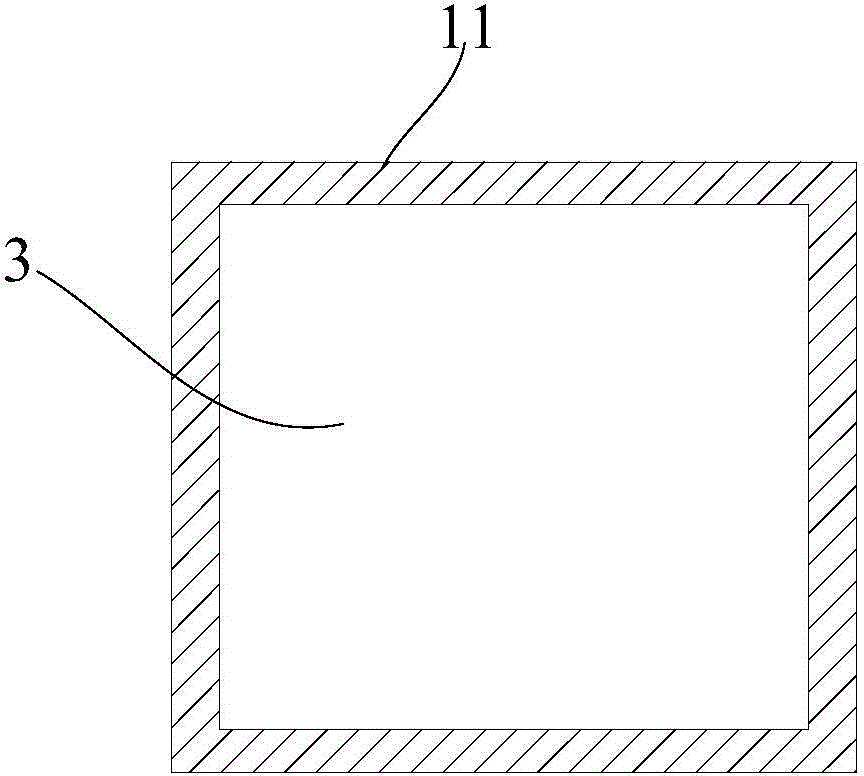

Embodiment 1

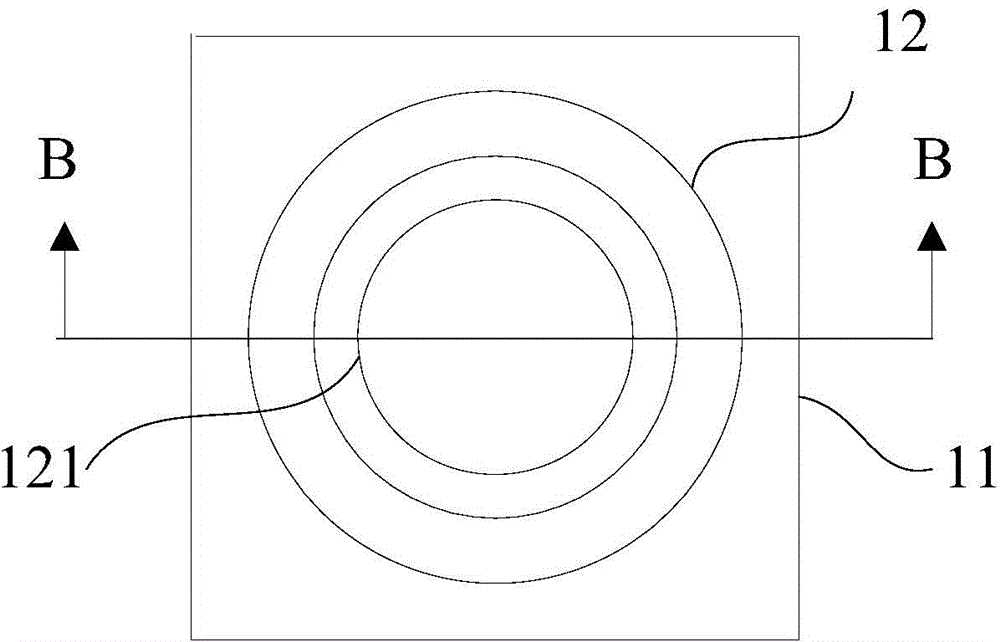

[0039] like image 3 , Figure 4 As shown, the clamping portion 121 is annular, and the outer peripheral wall of the clamping portion 121 is fixed on the inner wall of the lens barrel 12 . Simple structure and easy processing.

Embodiment 2

[0041] like Figure 5 , Figure 6 As shown, the clamping portion 121 includes at least three claws, and the claws are arranged along a circumference of the inner wall of the lens barrel 12 . The area occupied by the clamping part is small, which is beneficial for the light to be fully irradiated on the filter, and the function of the filter itself can be fully exerted, and the imaging quality is high.

[0042] On the basis of above-mentioned embodiment:

[0043] like Figure 4 , Figure 6As shown, in order to improve the stability of the camera module structure, the part of the bottom 121 a of the clamping part for contacting the optical filter 3 is located on the same plane. The surface of the filter is flat, and the larger the contact area of the clamping part is, the higher the stability will be. Therefore, when the part of the bottom of the clamping part in contact with the filter is on the same plane, the contact with the filter When the surface is matched, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com