State monitoring system and wind power generation system provided with same

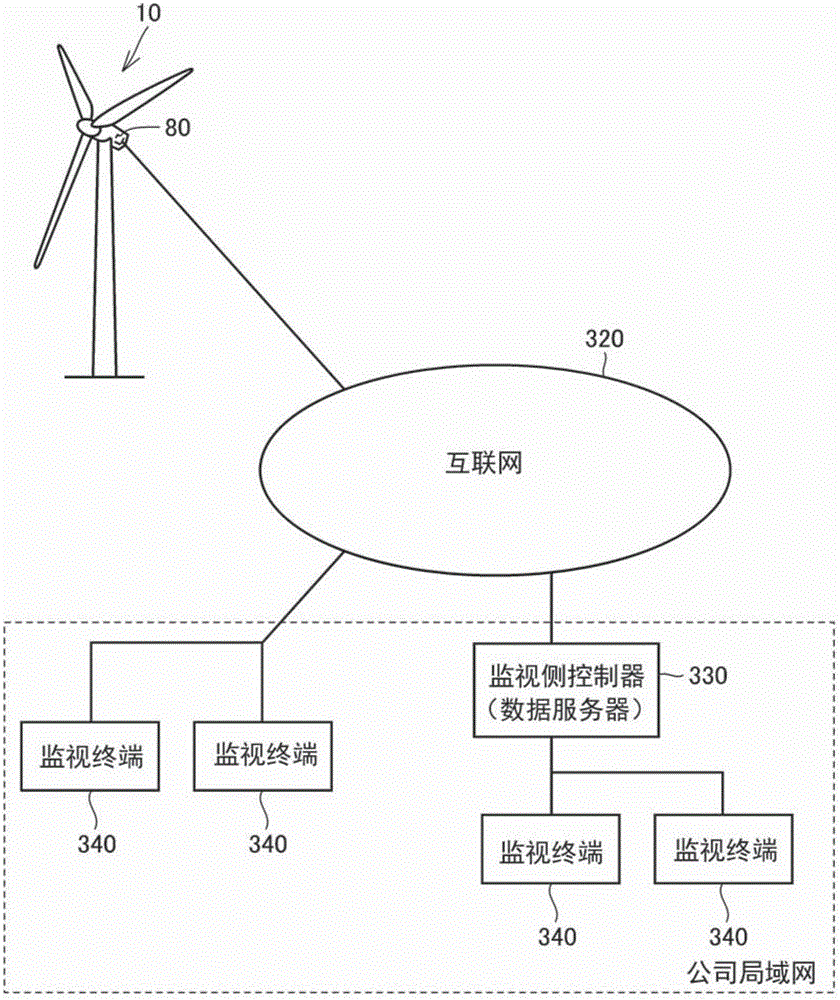

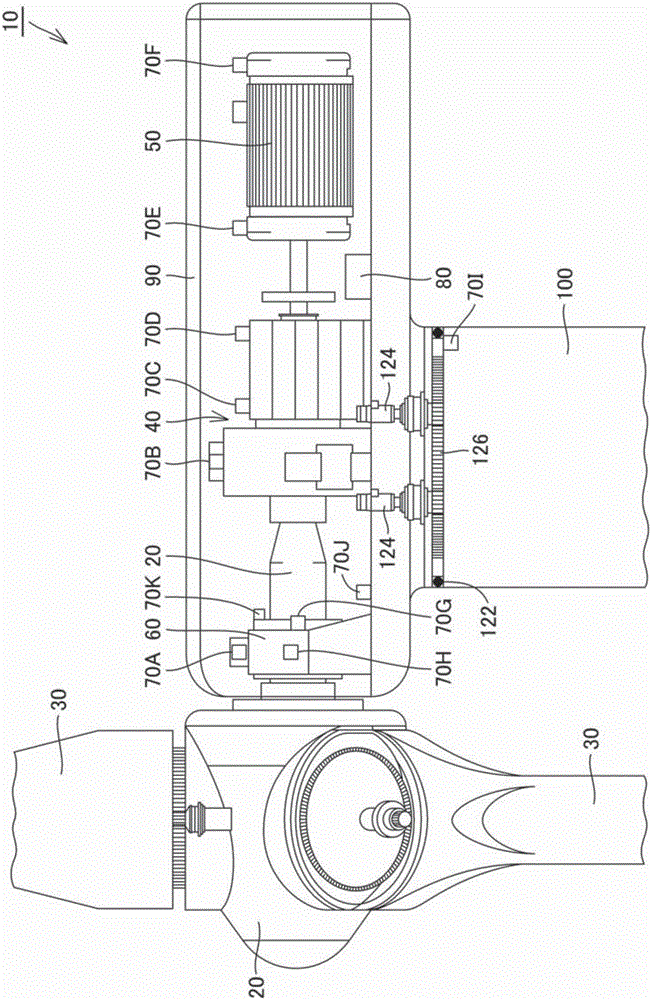

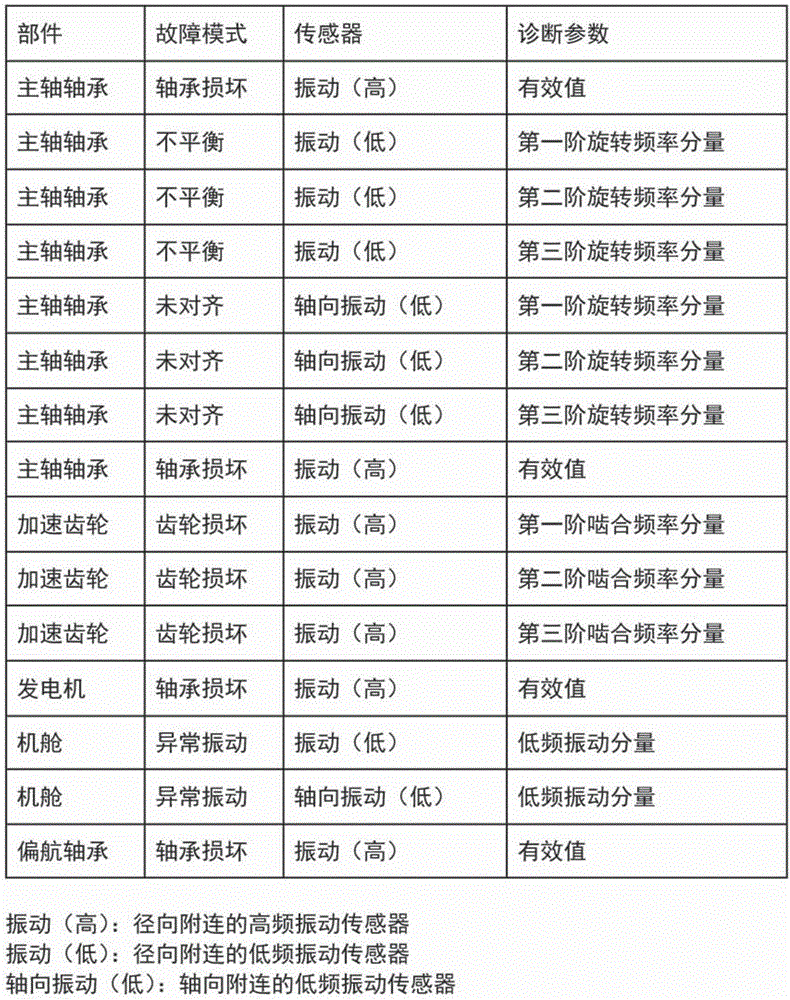

一种监视系统、状态的技术,应用在风能发电、风力发动机、风力电机组合等方向,能够解决大尺寸、不容易等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

[0111] In the first embodiment described above, the main shaft 20 (including the stopped main shaft 20 ) having the rotational angular velocity ωm within the specified range is defined as the yaw bearing diagnosis, operating state, and therefore, when the wind state (or wind speed) changes frequently , diagnostic parameters may not be adequately collected.

[0112] Therefore, in this second embodiment, the diagnostic parameters collected without imposing conditions on the rotational angular velocity of the main shaft 20 are corrected according to the rotational angular velocity ωm of the main shaft 20, and the failure of the yaw bearing 122 is diagnosed based on the diagnostic parameters. For diagnosis, the influence of the rotation of the main shaft 20 on the diagnosis parameters is suppressed.

[0113] The second embodiment provides a condition monitoring system with an overall configuration, a wind turbine 10 with a configuration, and with the same diagnostic parameters and...

no. 3 example

[0144] Although in the second embodiment, the diagnostic parameters of the yaw bearing 122 are corrected according to the rotational angular velocity ωm of the main shaft 20 , the diagnostic parameters may be corrected according to the amount of electric power generated by the generator 50 instead of the rotational angular velocity ωm of the main shaft 20 . In other words, the change in the amount of electric power generated is linked to the change in the transmission torque acting on the acceleration gear 40 , and also appears as a change in vibration near the yaw bearing 122 . Therefore, in the third embodiment, the diagnostic parameters of the yaw bearing 122 are corrected according to the amount of electric power generated by the generator 50 .

[0145] Correcting the diagnostic parameters of the yaw bearing 122 according to the amount of electric power generated by the generator 50 can be accomplished in a manner similar to that of the second embodiment. In other words, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com