Predictive maintenance method and system for transformer oil chromatography on-line monitoring device

A monitoring device and transformer oil technology, applied in measuring devices, predictions, neural learning methods, etc., can solve problems such as harsh operating environment, low operating life, and high professional requirements for personnel, so as to improve the level of operational reliability, early detection, and timely The effect of overhaul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

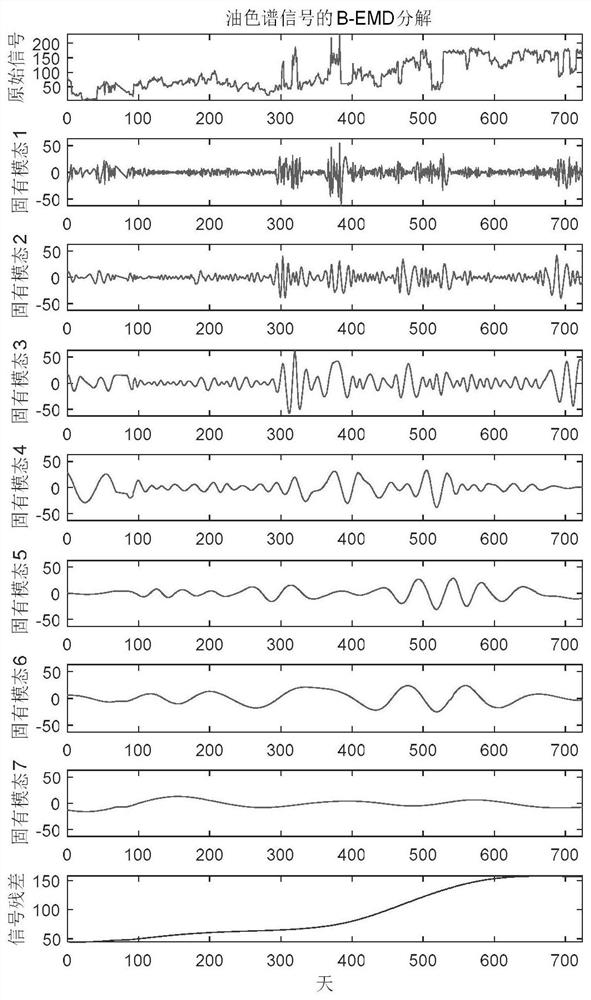

[0119] The gas components detected by the current oil chromatography online monitoring device include H 2 、CH 4 、C 2 h 4 、C 2 h 6 、C 2 h 2 , CO, CO 2 , 7 characteristic gases, but most of the existing online monitoring devices can only monitor the first 5 gases. In this embodiment, a total of 540,000 effective records of 354 oil chromatography online monitoring devices in a province were collected from 2007 to 2019 (removing obvious abnormal data such as data interruption, zero value, and infinity), and a sample library was established by using the sliding pane method. Sliding pane length = 30 days, step size = 5 days, such as Figure 6 As shown, a total of 32774 effective training samples were obtained.

[0120] The computer used in this embodiment is equipped with 8-core Xeon CPU, GTX1080TI graphics card and 32G memory, retrieves 441 pieces of relevant oil chromatography online monitoring and verification record data from the PMS database, and marks 4541 samples acc...

Embodiment 3

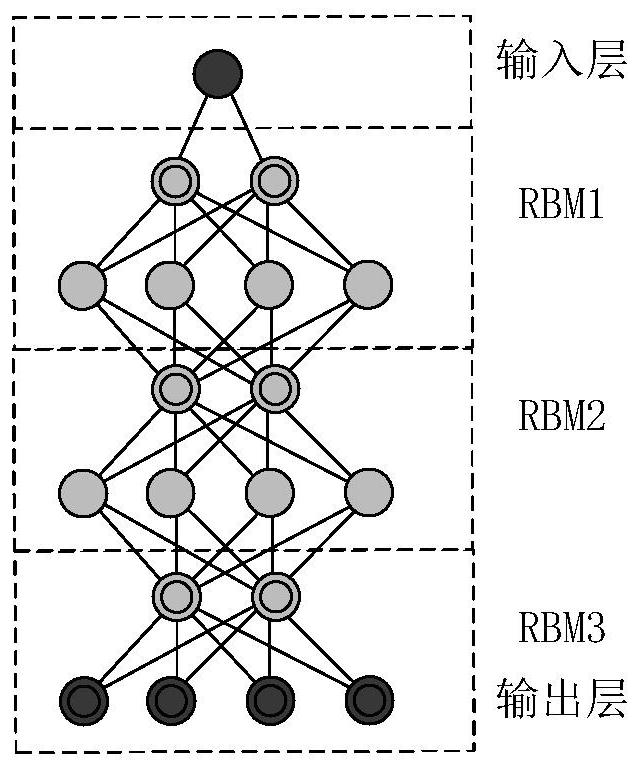

[0125] On the basis of Example 1, in order to obtain the best DBN structure and training parameters, this example compares the evaluation effect of the model on the oil chromatographic monitoring data under different Boltzmann machine layers and training cycles, so that according to The actual characteristics of the input samples construct the optimal DBN model.

[0126] see Figure 11 , the recognition accuracy of the DBN model tends to converge after the number of network layers reaches 4 and the training cycle reaches 250. If the number of model layers or training cycle is increased at this time, the training and testing time will be increased, which will affect the calculation efficiency. Therefore, for the actual situation of the data in this embodiment, a 4-layer DBN model is selected, and the number of training cycles is 250.

[0127] In order to verify the effectiveness of the oil chromatographic monitoring data of the method of the present invention, this embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com