Method for adjusting the bias in a bearing assembly and bearing assembly

A bearing assembly and preload technology, applied in the direction of bearings, shafts and bearings, rolling contact bearings, etc., can solve the problems of complexity, less complicated methods, and inaccurate possibilities, and achieve the effect of eliminating the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

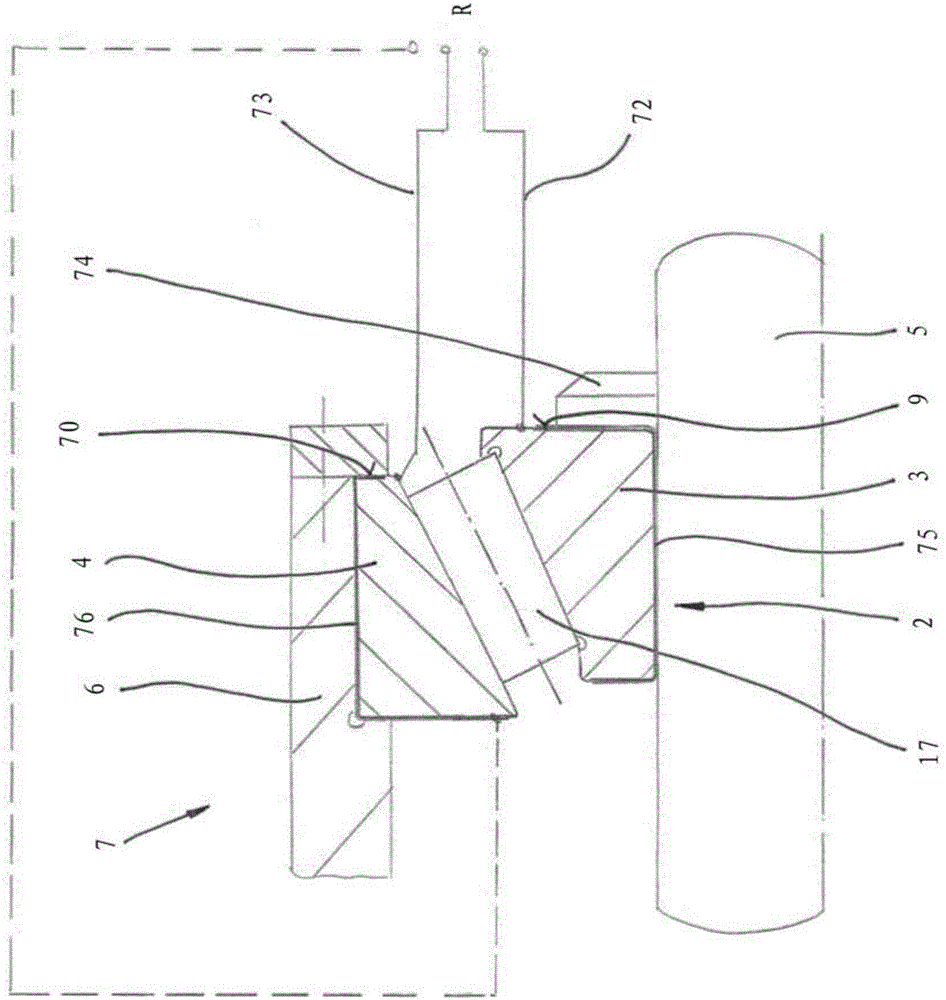

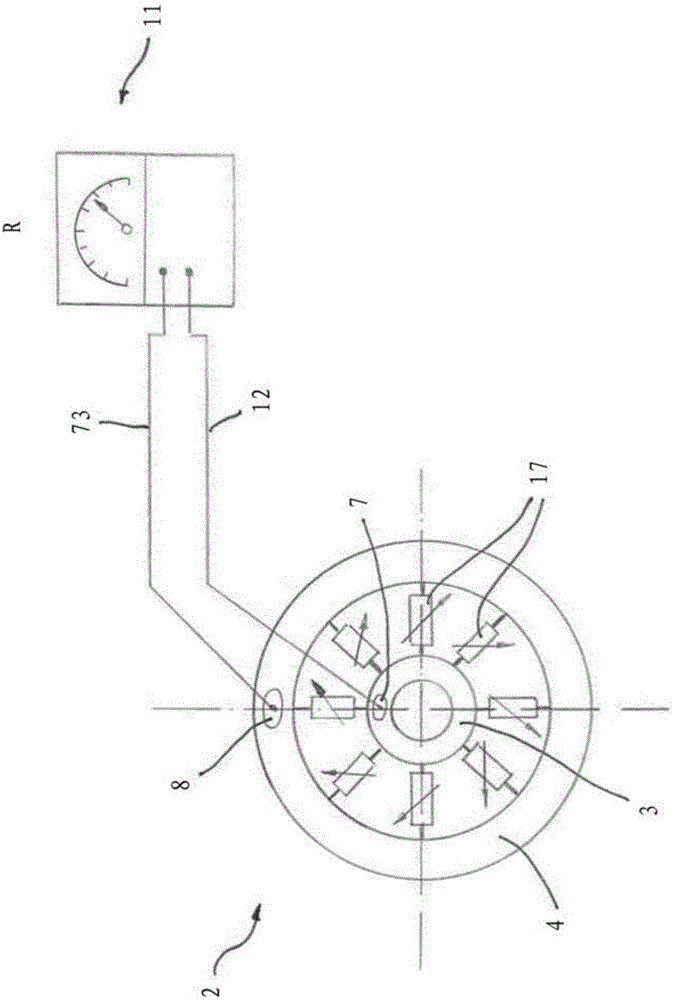

[0029] exist figure 1 In , a bearing assembly 1 is shown, with the use of which a shaft 5 is supported in a housing 6 . For this, two rolling bearings 2 in the form of tapered roller bearings are used which are preloaded against each other, of which only one such as figure 1 shown; another bearing not shown is also a tapered roller bearing and is set in figure 1 on the left side in such that the two bearings are positioned in a back-to-back arrangement. The rolling bearing 2 has a bearing inner ring 3 and a bearing outer ring 4 , between which rolling elements 17 are arranged.

[0030] At the point of contact with the attachment (shaft 5 and housing 6 ), the two bearing rings 3 and 4 comprise electrical insulation 15 or 16 . Current is thus prevented from flowing from the bearing rings 3 , 4 to the attachments 5 , 6 .

[0031] However, on their end sides 9 or 10, the two bearing rings 3, 4 each comprise a non-insulated point 7 or 8, as figure 2 shown. The rolling bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com