Device for feeding mass flow of rod-shaped products and use of the same

A technology for shaped products and supply, applied in applications, conveyors, cigarette manufacturing, etc., which can solve problems such as limited feasible solutions and double size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In the figures, identical or similar elements and / or parts are each provided with the same reference numerals, so that it can be seen accordingly from the further description.

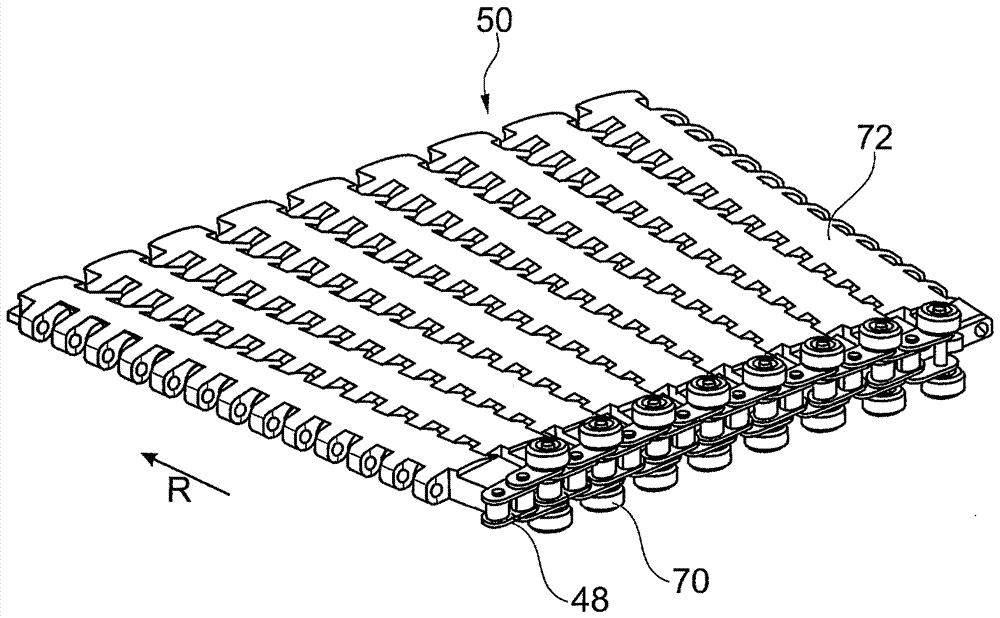

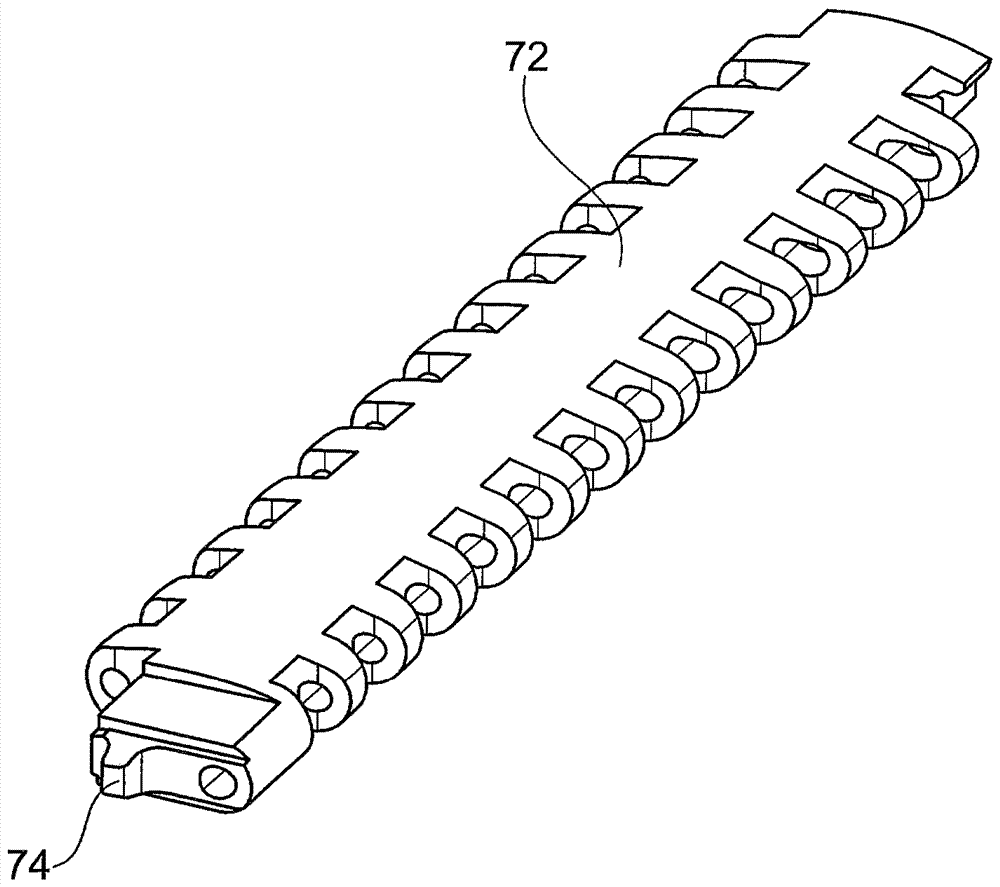

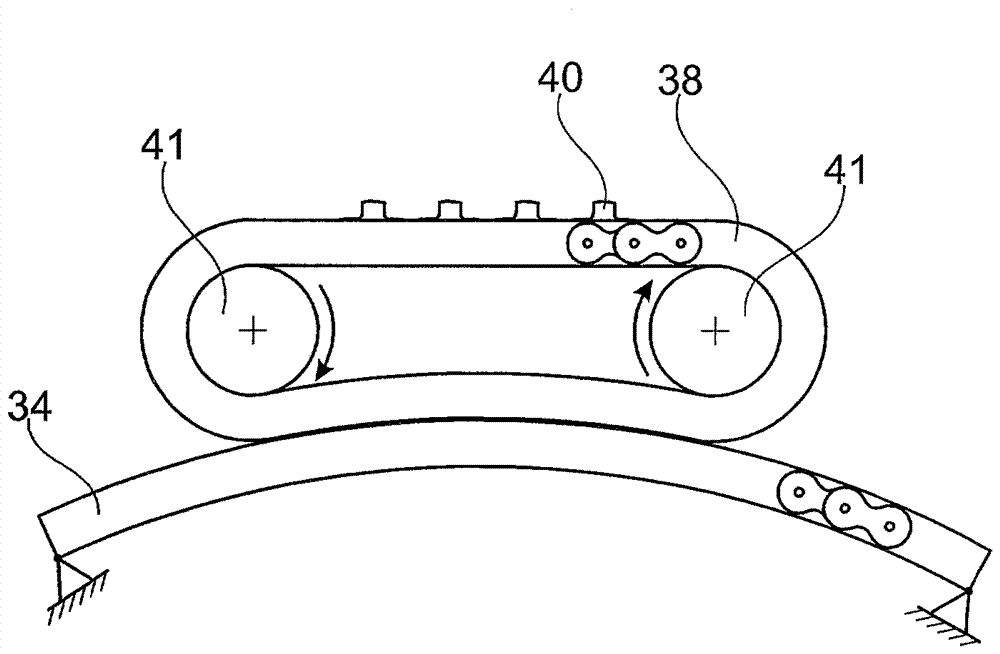

[0077] figure 1 A device 2 for supplying a mass flow of rod-shaped products, in particular rod-shaped products, of the tobacco processing industry is shown. The device 2 is a variable quality accumulator for compensating production fluctuations or differences in the production speed or output or throughput of the individual machines connected one behind the other. For example, said device 2 is connected between a cigarette machine which discharges a mass flow of cigarettes as rod-shaped articles and a wrapper. As rod-shaped products of the tobacco processing industry, besides cigarettes (filter cigarettes or ordinary cigarettes), filter rods, cigarillos, cigarette butts or other products of the tobacco processing industry are also provided. The supplied mass flow comprises a single-layer, typi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com