Preparation method of porous plate ceramic nanofiltration body based on silicon-zirconium sol

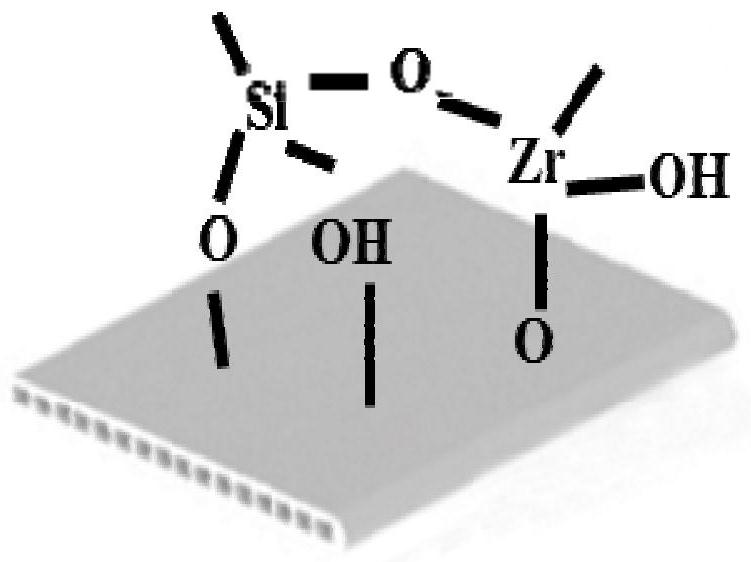

A technology of silicon-zirconium sol and flat plate, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve the problem of uneven filter pore size on the filter membrane, weak combination of filter membrane and carrier, inorganic nanofiltration membrane Complicated preparation process and other issues to achieve the effect of increasing hydrothermal stability and reducing pre-loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) SiO 2 -ZrO 2 Sol preparation

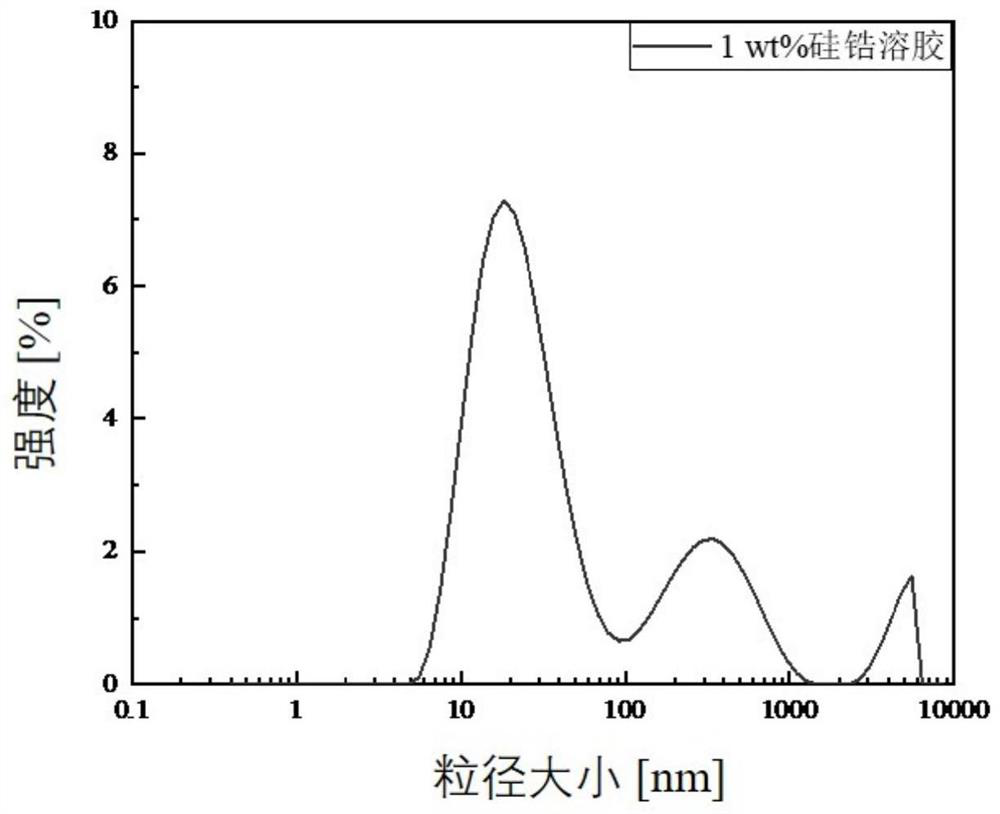

[0029] Take ethyl orthosilicate and zirconium n-butoxide in the same molar ratio, dissolve them in absolute ethanol, add distilled water and hydrochloric acid in turn under continuous stirring, and finally form ethyl orthosilicate: zirconium n-butoxide: ethanol: The molar ratio of hydrochloric acid is 1:1:10:2. By adjusting the content of water, the mass fraction of ethyl orthosilicate + zirconium n-butoxide is maintained at 1wt%, and then the solution is heated to 100°C and boiled for 15 minutes, and then added Water cooling (approximately 50 °C) equal to boiling evaporation, repeat this step, and keep stirring for 8 hours to form stable SiO 2 -ZrO 2 Sol, the particle size is measured by dynamic light scattering technique, such as figure 2 As shown, the mixed sol particle sizes of 25nm, 300nm and 5000nm are finally formed.

[0030] (2) Pretreatment of porous flat ceramic support body

[0031] Put the porous flat ceramic support...

Embodiment 2

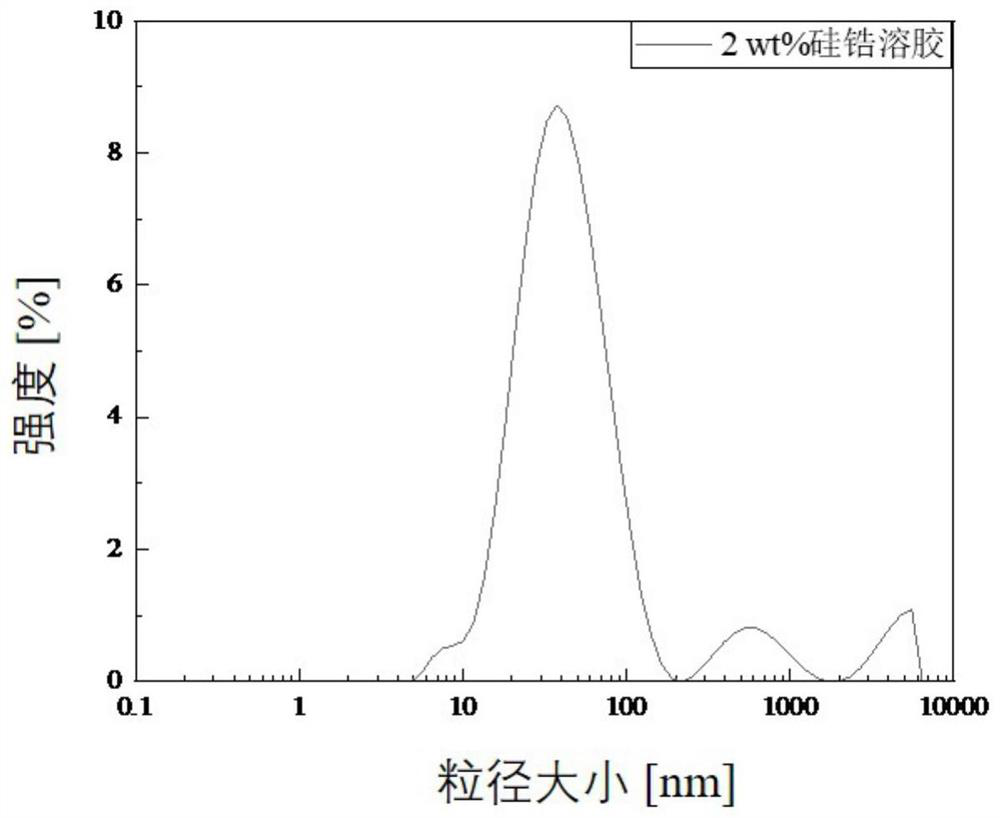

[0035] The difference between the sol and Example 1 is that by reducing the water content, SiO with a mass fraction of orthoethyl silicate + zirconium n-butoxide with a mass fraction of 2wt% is prepared. 2 -ZrO 2 The sol, through the particle size test, is a mixed sol particle size of 40nm, 600nm, and 5000nm, such as image 3 shown. In SiO 2 -ZrO 2 / For the preparation of porous flat ceramic membranes, the support was impregnated into 2wt% SiO 2 -ZrO 2 In the sol, the number of dipping times is 5 times, and the formed SiO 2 -ZrO 2 / The porous flat ceramic membrane has a pore size of 10nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com