a harvest processor

A processing machine and frame technology, applied in harvesters, agricultural machinery and implements, agriculture, etc., can solve the problems of large overall size, inconvenient use, inflexible operation movement, etc., to achieve flexible operation movement, small overall size, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

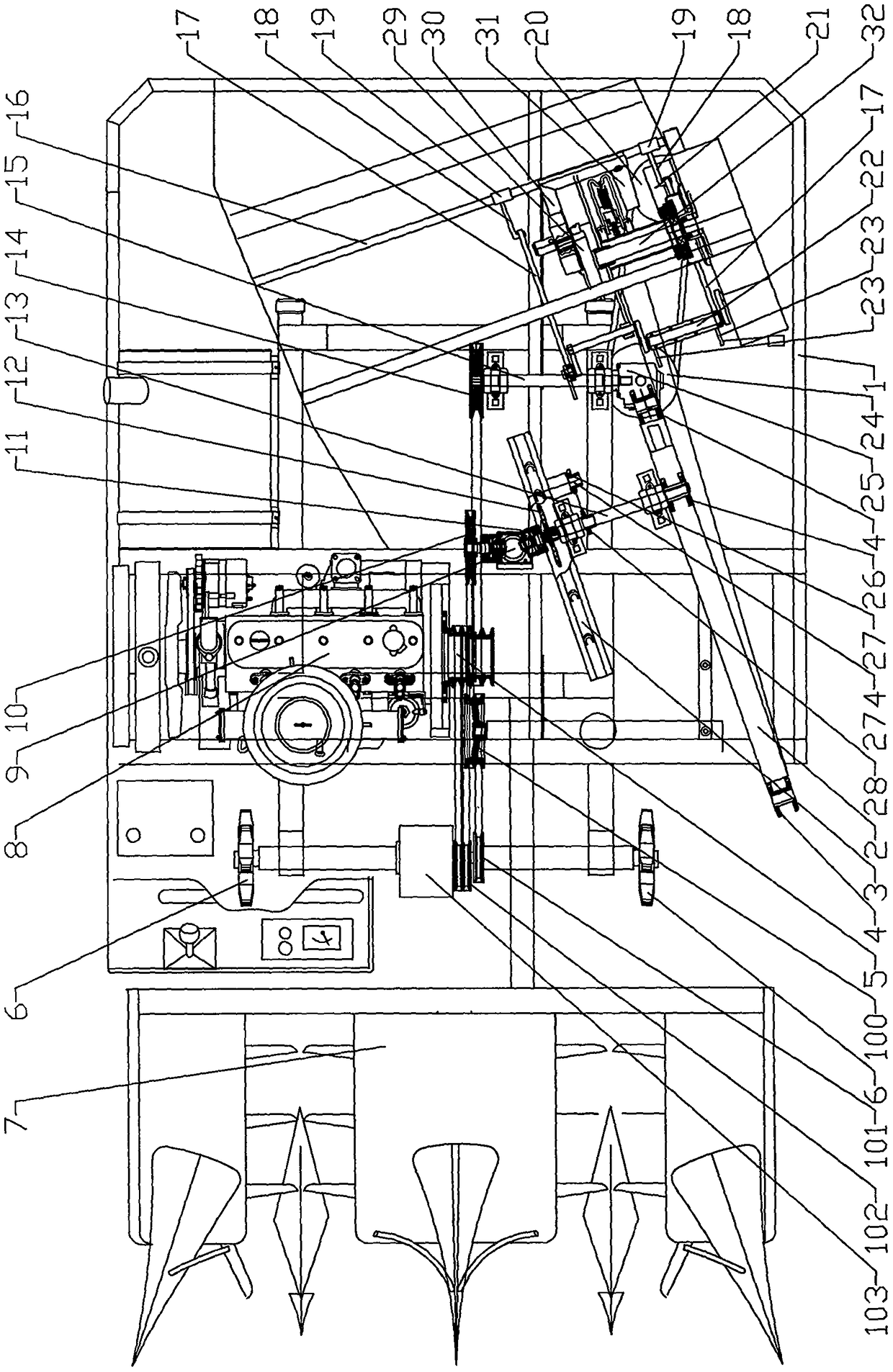

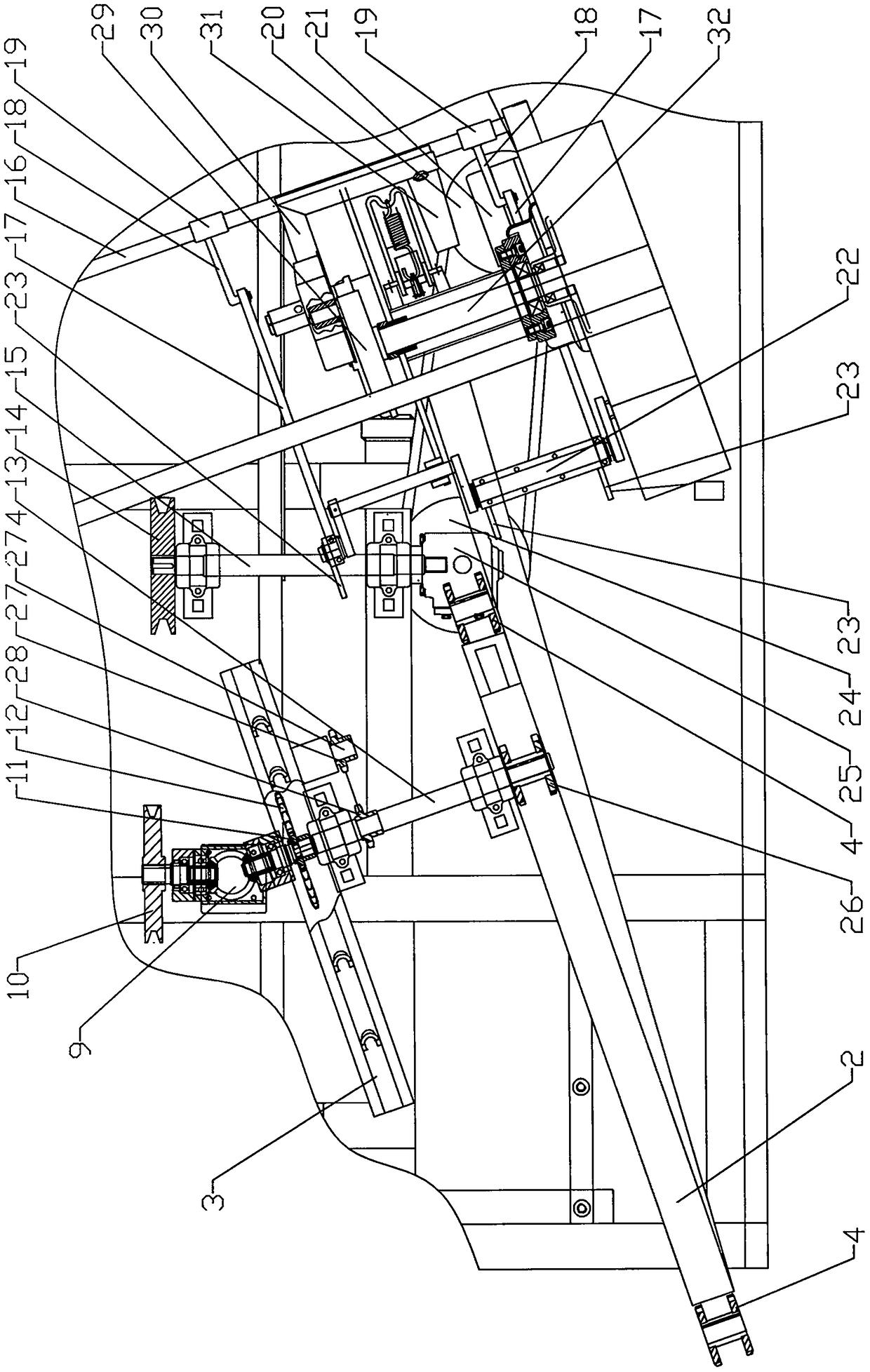

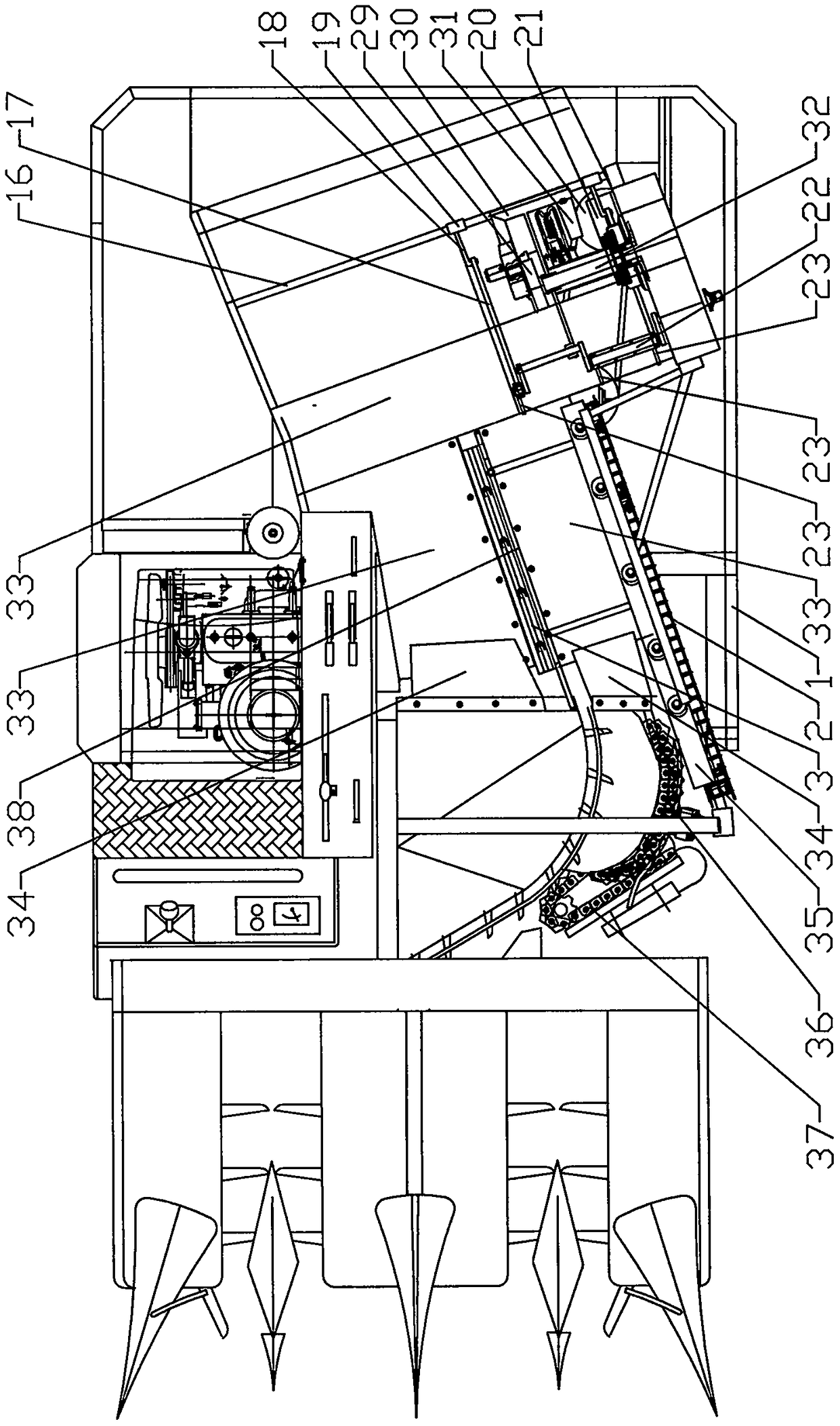

[0028] Example: as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4Shown, a kind of harvest processing machine comprises frame 1, and the front part of frame 1 is provided with header 7 and speed changer 103, and the lower part of frame 1 is provided with crawler drive wheel 6, and frame 1 is provided with feeding conveyor Chain 37, intermediate conveying chain 36, horizontal conveying device and the bundling and bundling mechanism matched with the horizontal conveying device, the frame 1 is provided with a power transmission device for the power transmission of the horizontal conveying device and the bundling and bundling mechanism, the The bundling and bundling mechanism includes a bundling device and a bundling device. The material is conveyed to the horizontal conveying device through the feeding conveyor chain 37 and the intermediate conveying chain 36, and the material is conveyed to the bundling and bundling mechanism through the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com