Concealed connecting rod intersecting type hydraulic ascending and descending rubbish transfer box

A garbage transfer box, hydraulic lifting technology, applied in the direction of garbage cans, garbage collection, household appliances, etc., can solve the problems of troublesome operation, environmental pollution, easy dumping of garbage cans, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

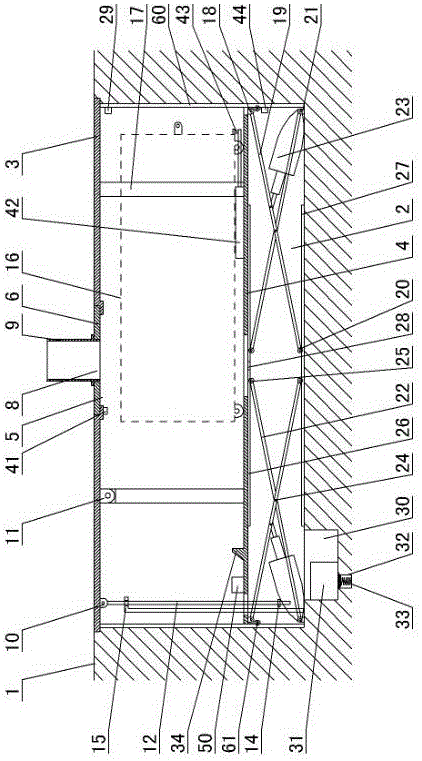

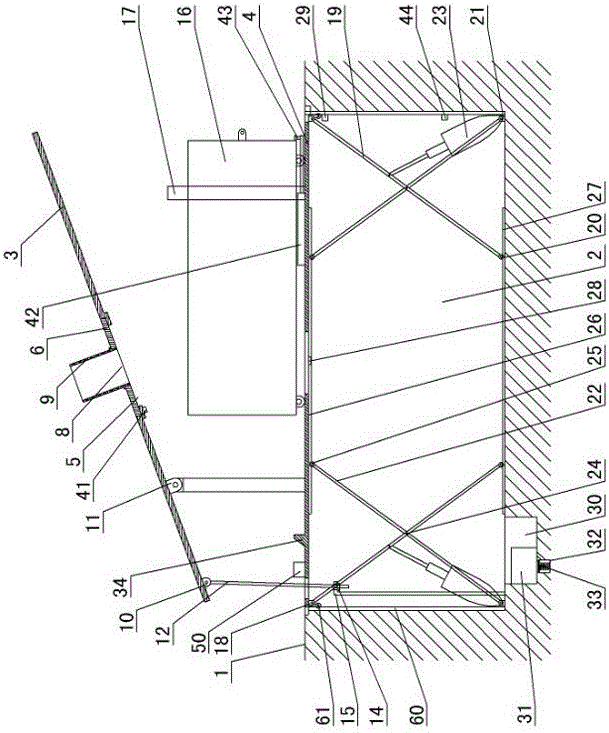

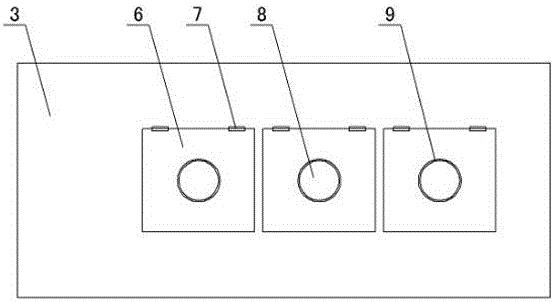

[0011] The invention relates to a hidden connecting rod cross-type hydraulic lifting garbage transfer box, such as figure 1 — Figure 4As shown, it is characterized in that: there is a pit 2 in the ground 1, a bracket 63 is arranged at the bottom of the pit, an upper cover 3 and a lower platform 4 are arranged in the pit, the upper cover is flat with the ground, and the upper cover is opened in the upper cover. There is a large garbage input port 5, and a large input port cover 6 is arranged in the large refuse input port. Input port 8, dustbin 9 is set on the small garbage input port, the first movable fulcrum 10 and the second movable fulcrum 11 are set under the loam cake 3, the first movable fulcrum connects the pull rod 12, and the adjustment nut 14 is set on the pull rod, A limit hook 15 is set in the pit, the pull rod passes through the limit pull hook, and the adjustment nut on the pull rod is in contact with the limit pull hook. The lower platform 4 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com