A two-step hydrothermal preparation method of lead zirconate titanate coated carbon fiber

A technology of lead zirconate titanate and carbon fiber, which is applied in the direction of carbon fiber, fiber treatment, chemical instruments and methods, etc., can solve the problems of lack of related reports on the preparation of chopped carbon fiber piezoelectric coating, avoid high-temperature treatment and achieve uniform coating The effect of good performance and saving product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A two-step hydrothermal preparation method of lead zirconate titanate coated carbon fiber, comprising the steps of:

[0034] (1) ZrOCl 2 ·8H 2 O (0.044mol) and Ti(OC 4 h 9 ) 4 (0.056mol) was dissolved in 60ml of hydrochloric acid solution (the volume ratio of concentrated hydrochloric acid and water was 1:1, the mass fraction of concentrated hydrochloric acid was 37%), after stirring for 4 hours, after mixing evenly, the precursor sol was formed.

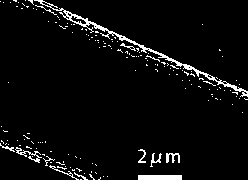

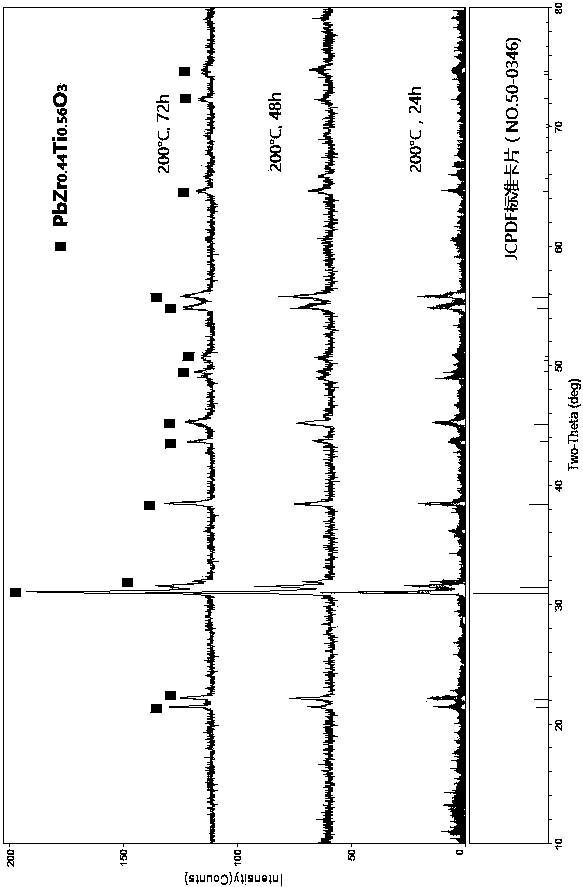

[0035] (2) Use concentrated nitric acid to surface-activate chopped carbon fibers with a length of 2-5 mm for 24 hours, then 0.1 g of surface-activated chopped carbon fibers are ultrasonically dispersed in the precursor sol for 30 minutes and then transferred to a 100ml autoclave. Place at 150° C. for 8 hours under a pressure of 10-15 atm to form zirconium titanate-coated carbon fibers.

[0036] (3) Preparation of Pb(NO 3 ) 2 Solution: 0.1molPb(NO 3 ) 2 Dissolved in 60ml of water, at the same time, the zirconium tita...

Embodiment 2

[0039] As described in Example 1, the difference is that the reaction temperature of the chopped carbon fibers in the autoclave in step (2) is 180° C., and the time is 8 hours.

Embodiment 3

[0041] As described in Example 1, the difference is that the reaction temperature of the chopped carbon fibers in the autoclave in step (2) is 150° C. and the time is 12 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com