Opposite type small-bore ultrasonic flowmeter

一种对射式、超声波的技术,应用在音量计量、测量流量/质量流量、液体/流体固体测量等方向,能够解决影响换能器准确定位、塑料管段变形大、加工方式复杂等问题,达到解决内部腐蚀及结垢问题、减少紊流、结构简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings in the embodiments of the present invention.

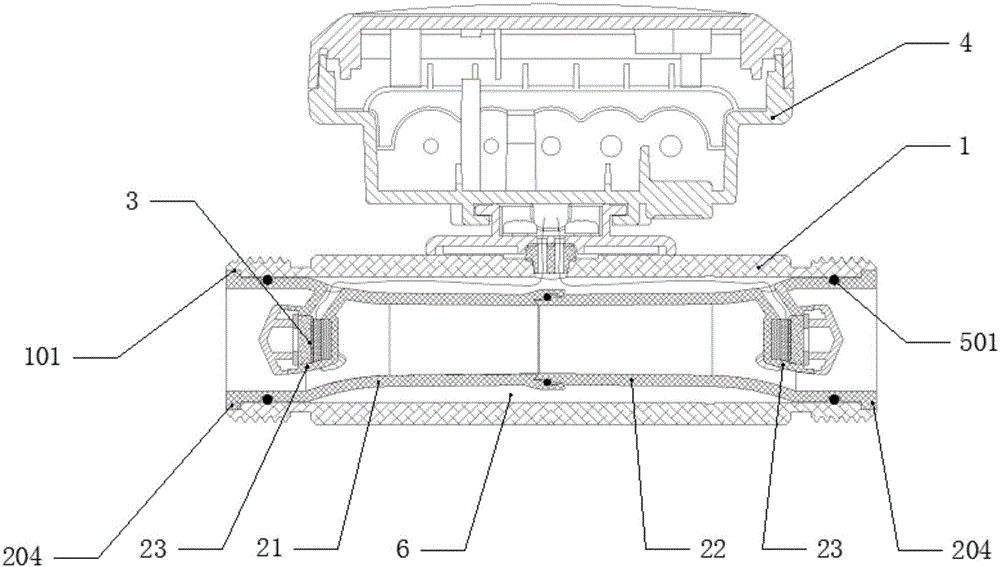

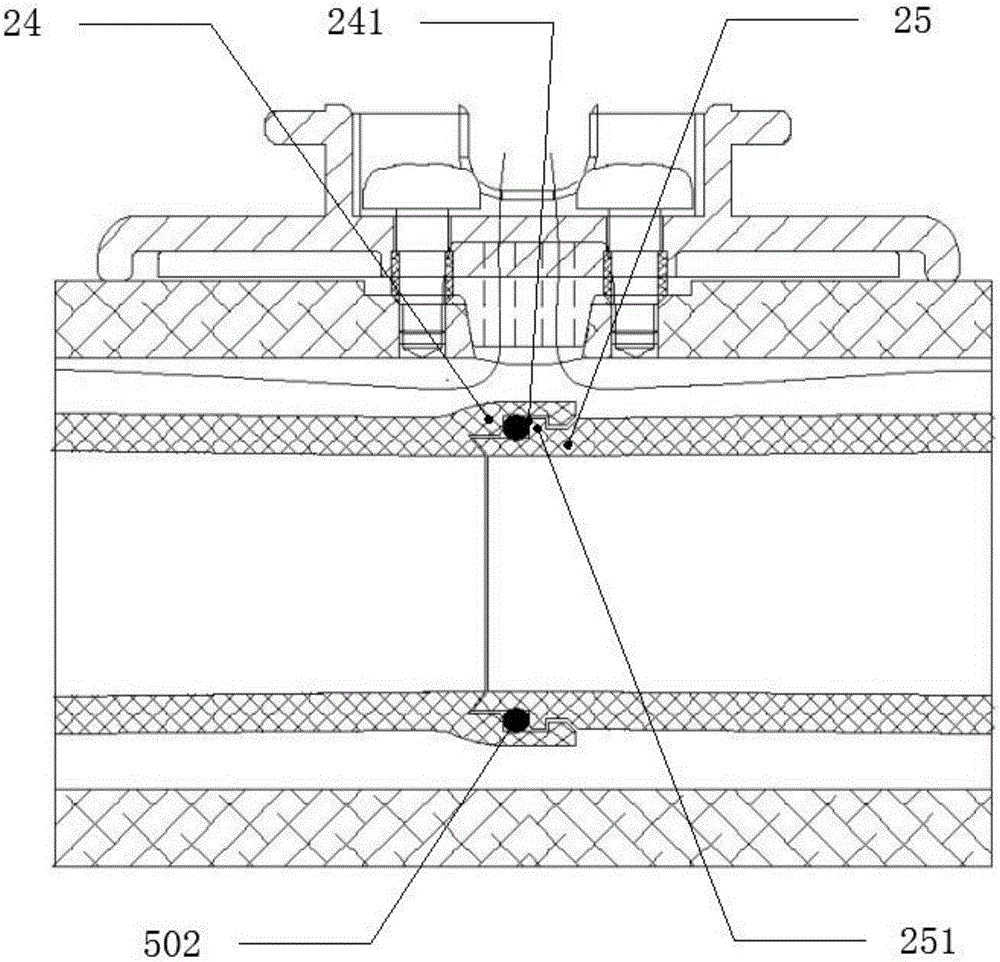

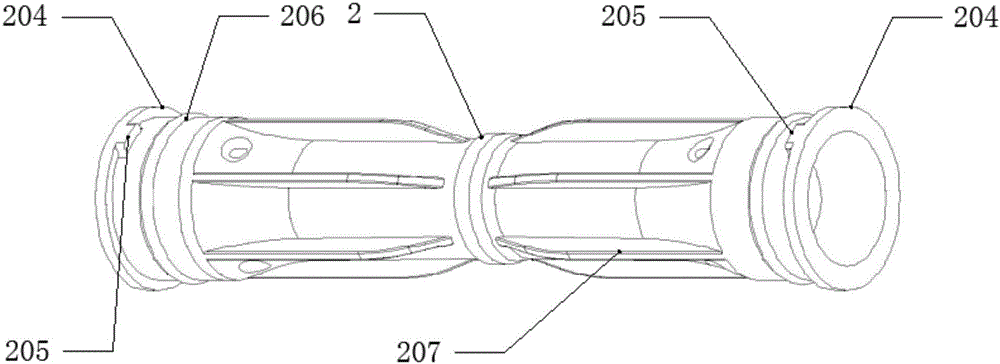

[0027] A small-diameter through-beam ultrasonic flowmeter, such as figure 1 As shown, it includes the outer layer 1 of the pipe section, the inner layer 2 of the pipe section, the transducer assembly 3, and the circuit box 4. The circuit box 4 is arranged on the outer layer 1 of the pipe section, and the inner layer 2 of the pipe section is integrally formed by injection molding. , the end of which is formed with a transducer mounting seat 23, the transducer assembly 3 is installed in the mounting seat 23, two pairs of transducer assemblies 3 are arranged in pairs, the outer layer 1 of the pipe section is a standard pipe, and the two ends Processed with external thread, used to connect into the measuring pipeline. The inner layer 2 of the pipe section is installed in the outer layer 1 of the pipe s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com