Adjustable cargo conveying mechanism and application method thereof

A technology for conveying mechanisms and goods, which is applied to coin-free or similar appliances, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items, etc. The width of the track cannot be adjusted, etc., to achieve the effect of practicality and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

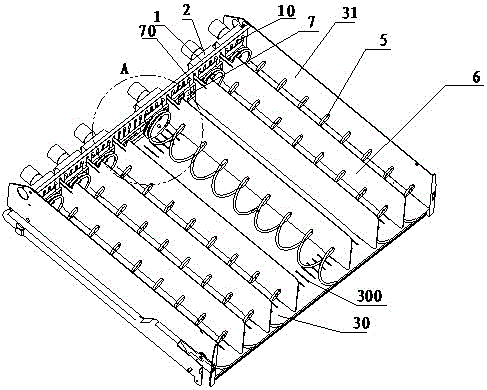

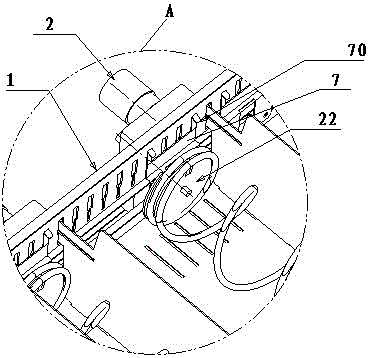

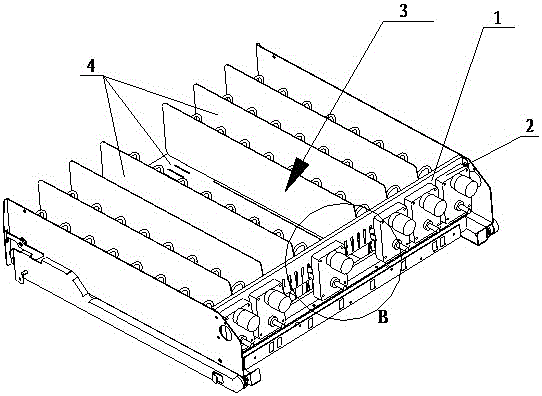

[0030] Such as Figure 1-8 As shown, an adjustable cargo conveying mechanism in this embodiment includes a strip-shaped mounting plate 1, and several vertical T-shaped bayonets 10 are evenly spaced along the length direction on the mounting plate 1, The inner surface of the mounting plate 1 is movable along the length direction with several motor boxes 2, and the outer surface of the mounting plate 1 is connected with a delivery warehouse 3, and the delivery warehouse 3 is arranged along the length direction of the installation plate 1. Correspondingly, there are several shipping channels 4 extending toward the shipping direction, and the shipping channels 4 are set in one-to-one correspondence with the motor box 2, and the shipping channels 4 are separated by several partitions 6 and the shipping warehouse 3. Formed, and the partitions 6 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com