Power semiconductor chip and formation method thereof

A technology for power semiconductors and chips, applied in semiconductor devices, semiconductor/solid-state device manufacturing, transistors, etc., can solve problems such as device loss and reliability reduction, and achieve the effects of improving reliability, improving uniformity, and uniform heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

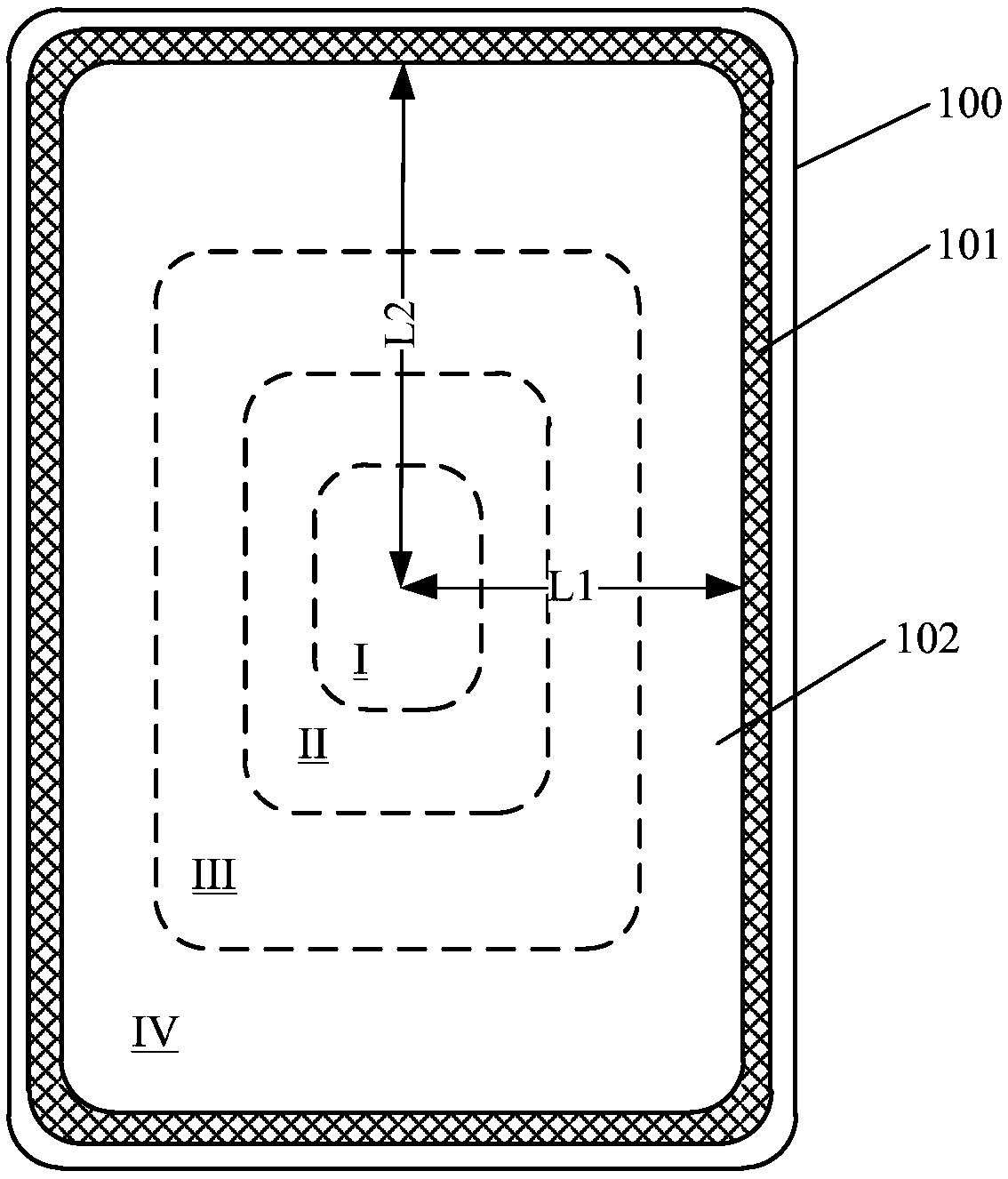

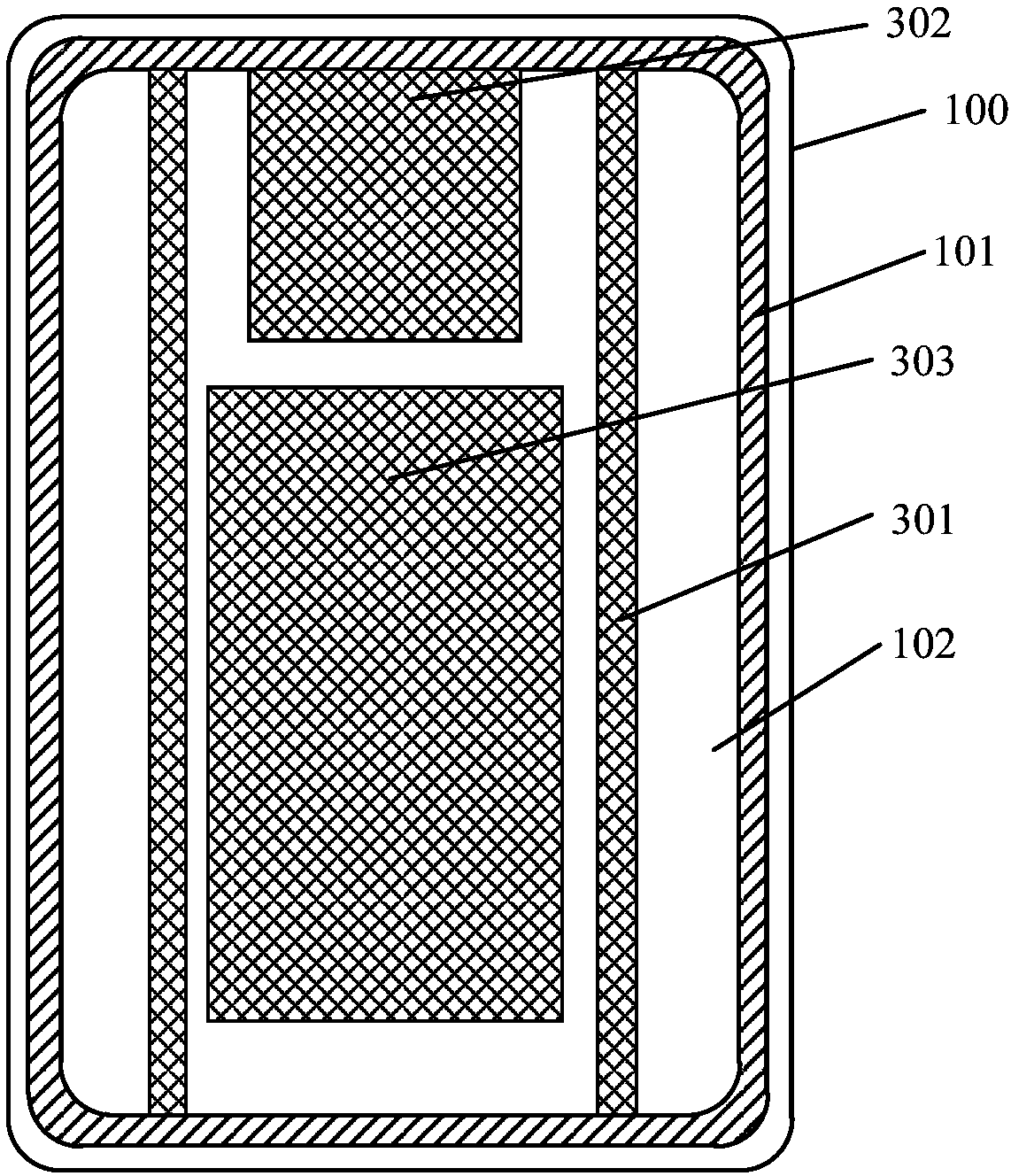

[0026] As mentioned in the background art, when the semiconductor device in the prior art works in a saturated state, a very large loss will be generated on the device, and the reliability will be reduced. The inventors have found that the reduction in reliability of power semiconductor devices is mainly due to the uneven heat distribution inside the device chip in a saturated state, and the temperature at the center of the chip is higher than that at the edge of the chip. This is because the heat generated in the center of the chip is greater than that in the edge area Due to the heat generation, the cells in the central area are easily damaged, and the device loss increases, thereby reducing reliability.

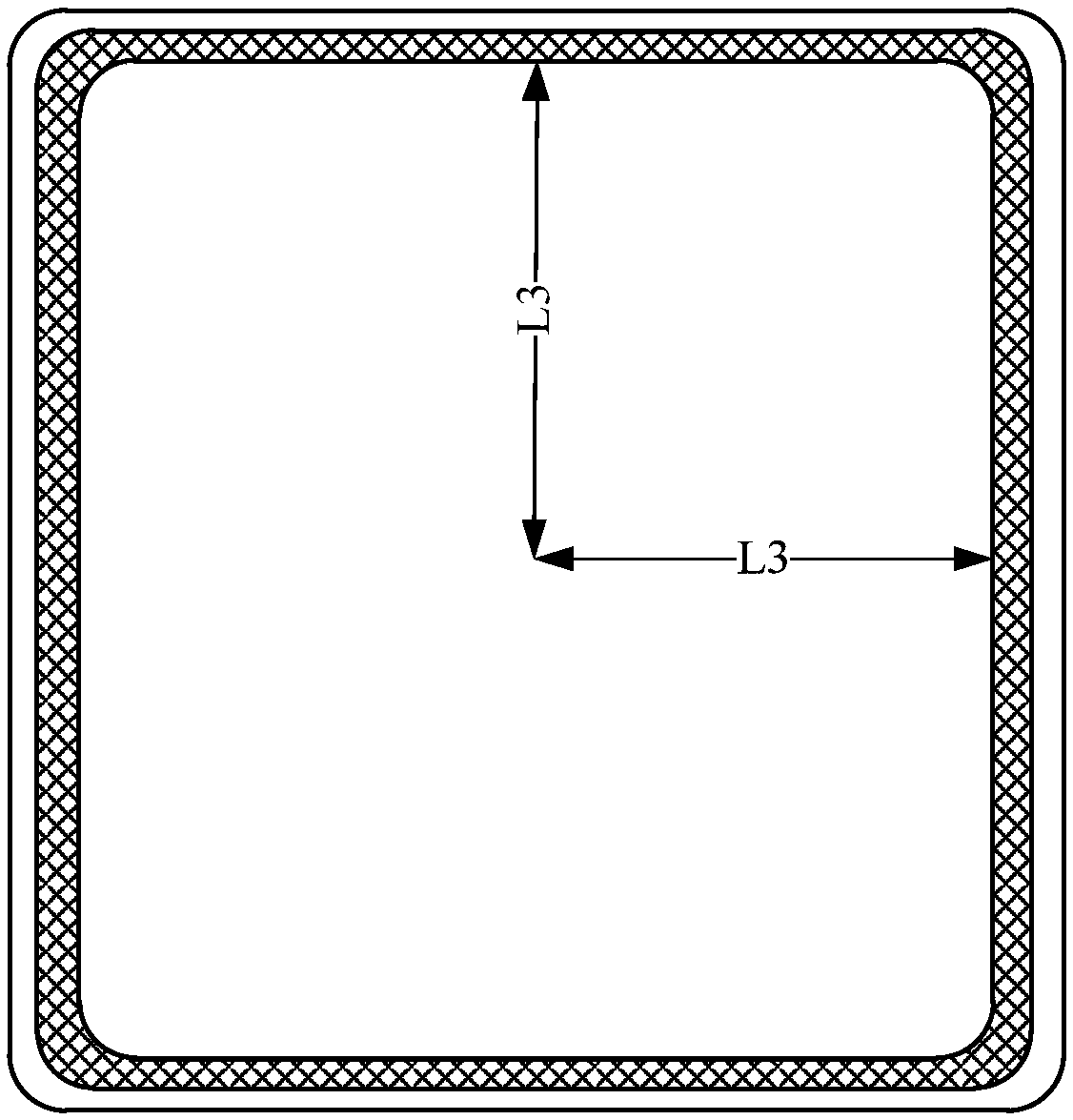

[0027] By reducing the length of the cell channel in the central area of the chip, the present invention realizes the reduction of the calorific value in the central area, so that the internal heating of the chip is uniform, thereby improving the reliability of the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com