Multi-degree-of-freedom machine

An all-in-one machine with a degree of freedom, which is applied in the direction of electromechanical devices, mechanical equipment, and mechanical energy control, can solve the problems of inconvenient use of model selection, and achieve the effects of facilitating design and model selection, reducing quantity, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

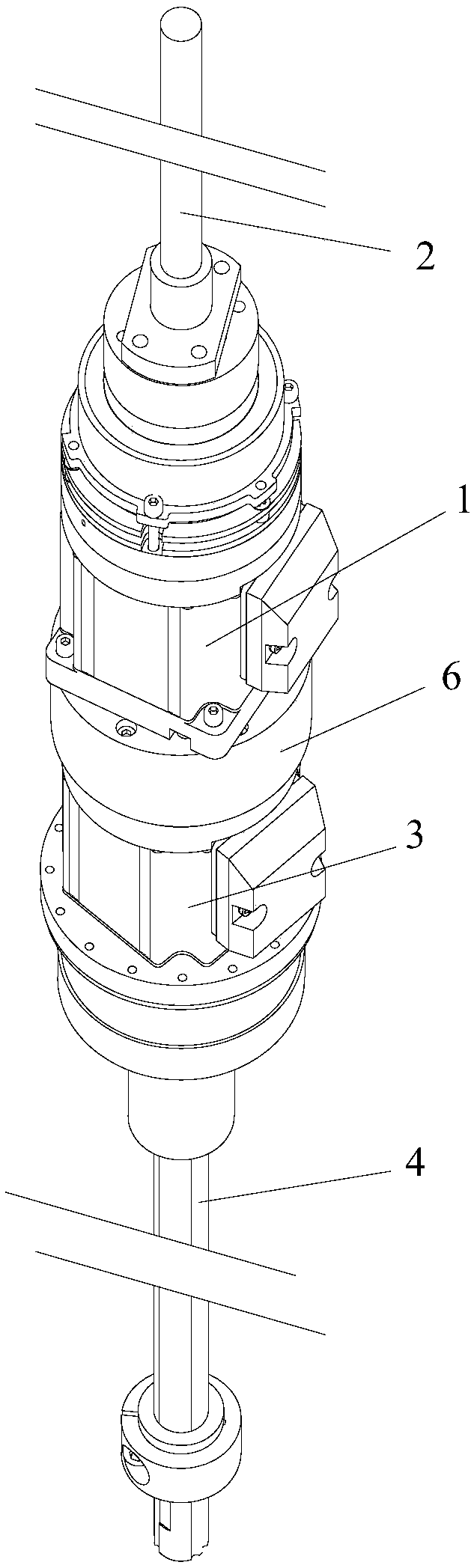

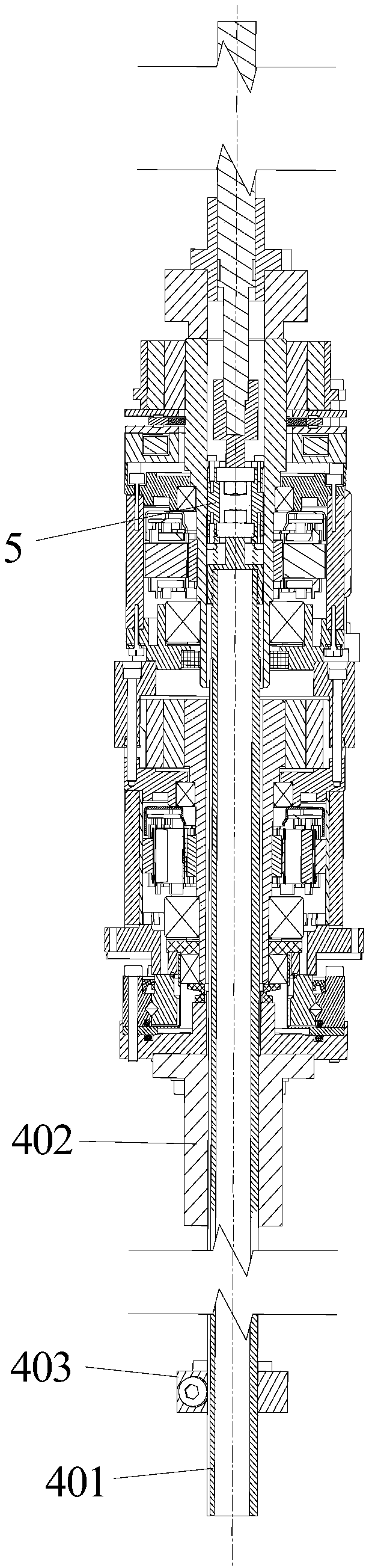

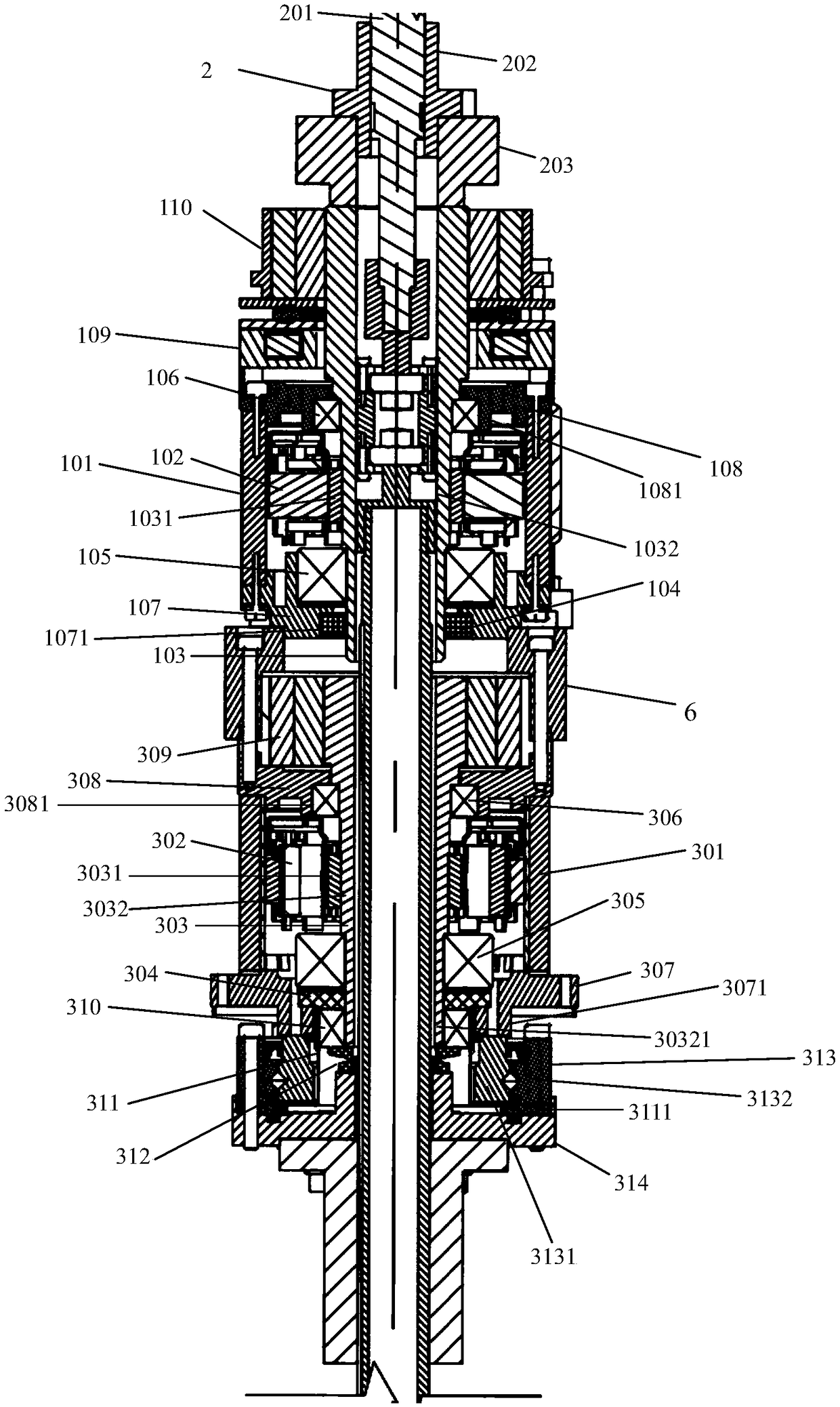

[0018] Such as Figure 1-Figure 3 As shown, the embodiment of the present invention includes: a motor module 1 , a ball screw module 2 , an all-in-one machine module 3 , a ball guide shaft module 4 , a connection module 5 , and a motor end cover adapter 6 .

[0019] The motor module 1 includes a first motor housing 101, a first stator 102, a first rotor 103, an oil seal 104, a first front bearing 105, a first rear bearing 106, a first front end cover 107, a first rear end cover 108, The first encoder 110 and the brake 109 .

[0020] The outer side of the first motor housing 101 is square, and the inner side is cylindrical.

[0021] The first stator 102 is a hollow cylindrical structure embedded in the cylinder of the first motor casing 101, which includes the first stator teeth 1021 and the first terminal board 1022, and the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com