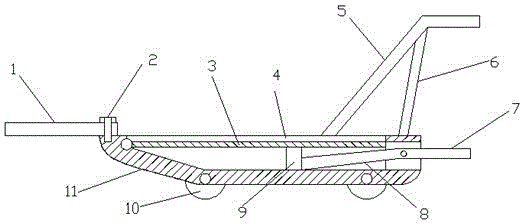

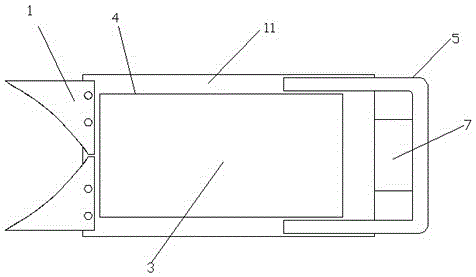

Hand-push type grain cutter

A hand-push and push-rod technology, applied in the field of mowers, can solve problems such as laborious and difficult to use, and achieve the effects of simple production, increased storage capacity, and improved labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

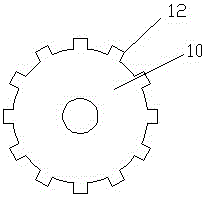

[0022] Implementation method: the laborer grasps the push rod 5 and pushes it, and the small wheel 10 reduces the resistance when sliding, so that it can also be pushed in a dry land. The cutter 1 cuts off the rice, and the cut rice is poured into the storage tank 4, and the storage tank 4. To increase the storage capacity, by stepping on the pedal 7, the movable bottom plate 3 can be lifted by using the principle of leverage, and the unloading can be easily completed, saving time and effort.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com