Integral cabinet body and the package board group thereof

A technology of integrated cabinets and packaging boards, applied to furniture parts, household appliances, furniture accessories, etc., can solve the problems of unsightly appearance, high cost, inconvenient assembly, etc., and achieve a strong sense of integrity, less consumables, and high assembly efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

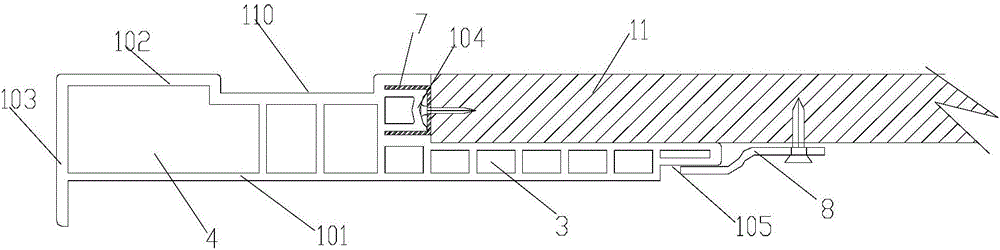

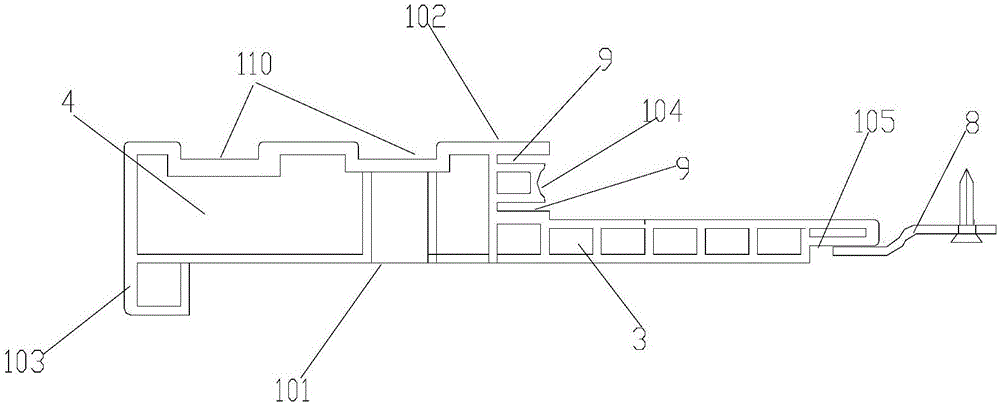

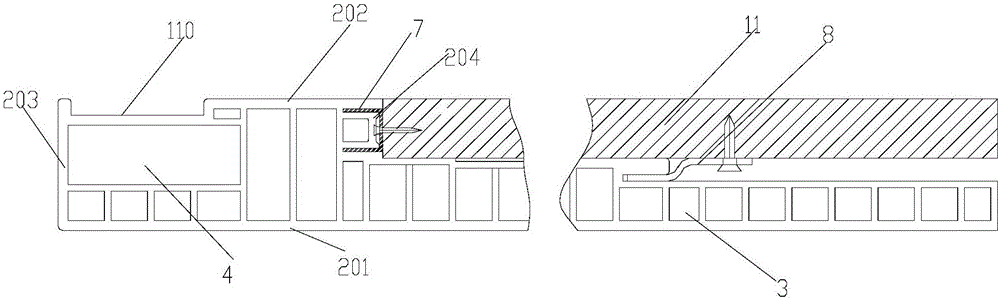

[0037] Example 1, such as Figures 1 to 8 and Figure 19 As shown, a packaging board group for an integrated cabinet includes a closing line 1 arranged on the wall side of the cabinet 14, a side sealing plate 2 arranged on the outside of the cabinet 14, a top line 5, a foot line 6 and a set of connection The closing line 1, the side sealing plate 2, the top line 5 and the foot line 6 are all integral moldings, which can be made of wood-plastic material or other convenient molding materials.

[0038] Specifically, the closing line 1 is a one-piece molded part, and its surface texture can be processed according to the specific needs of customers. The closing line 1 includes the closing line outer side 101 on the wall side, the closing line inner side 102 arranged on the same side as the inside of the cabinet, and the closing line outer end surface arranged at the closing line outer side 101 and the closing line inner side 102 ends. 103. The inner surface 102 of the closing li...

Embodiment 2

[0045] An integrated cabinet obtained by assembly of the above-mentioned packaging boards, such as Figure 9 , Figure 12 , Figure 13 and Figure 15 As shown, two cabinet body side panels 11 and a sliding door 12 are included, and the sliding door 12 is from the bottom of the cabinet body 14 to the top. The side plate 11 on the left side of the cabinet body 14 is arranged against the wall, and the side plate 11 on the right side is not arranged against the wall, and the depth of the cabinet body 14 is less than the length of the body of wall 15 . This kind of layout structure adopts the layout form of the closing line 1 on the left side and the side sealing plate 2 on the right side, and the outer end surface 103 of the closing line is against the wall. The end bolts of the side plates 11 are fixed with groove connectors 7 , and the outer surfaces of the left and right side plates 11 are bolted with pressure plate connectors 8 , and the closing line 1 is connected to the g...

Embodiment 3

[0047] An integrated cabinet, such as Figure 10 As shown, it includes two cabinet side panels 11 and sliding doors 12 on the left and right. A group of swing doors 13 are also arranged above the sliding doors 12, and a top line 5 of a planar structure is arranged above the swing doors 13. The top line 5 of the planar structure The top line 5 extends all the way to the top of the wall. Others are the same as embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com