Raw material dispersion device for vinyl resin reaction still

A vinyl resin and dispersing device technology, which is applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low raw material dispersion efficiency, poor stirring effect, and increased production costs, etc. , to achieve the effect of good raw material mixing effect, high raw material dispersion efficiency and reasonable structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

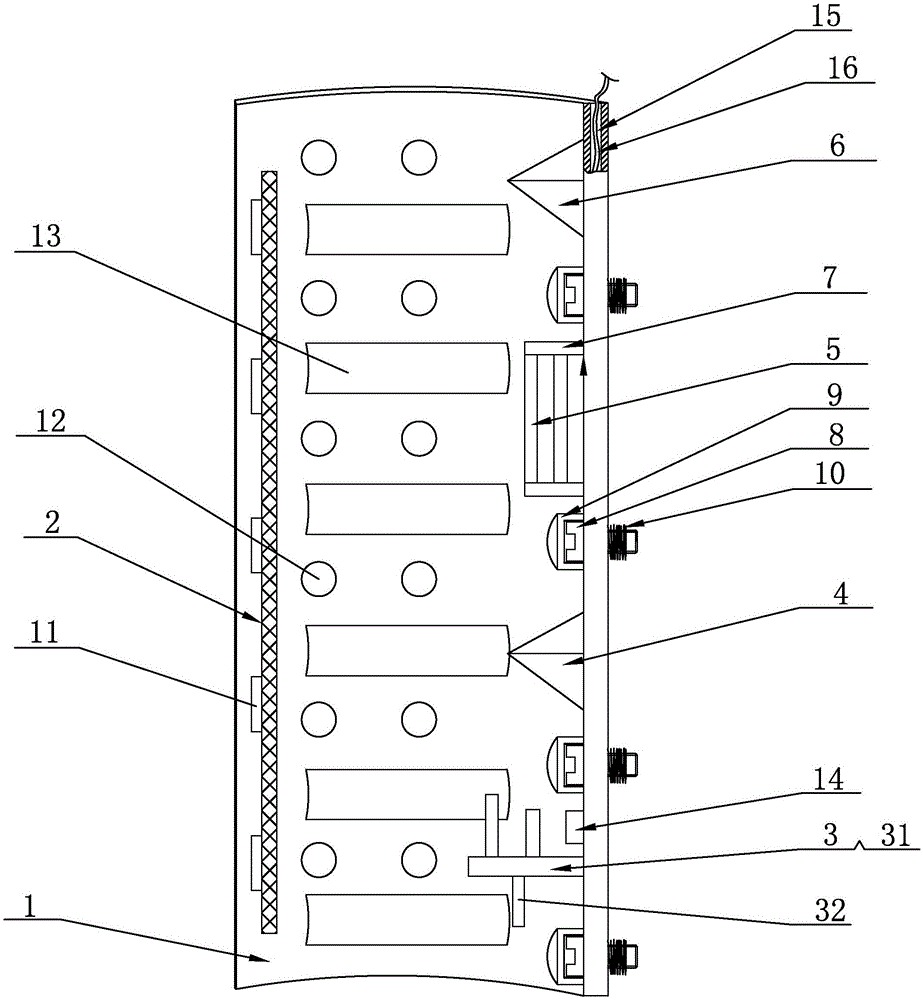

[0019] see figure 1 , a raw material dispersing device for a vinyl resin reactor disclosed in the present invention, comprising a connecting plate 1, the left end of the inner surface of the connecting plate 1 is integrally provided with a plurality of positioning projections 11 from bottom to top, and the positioning projections 11 The right end of the connecting plate 1 is welded with a raw material dispersing net 2, and the connecting plate 1 is provided with a plurality of screw holes 12, and the right end of the inner surface of the connecting plate 1 is sequentially welded with a raw material dispersing frame 3, a first raw material dispersing tooth 4, The raw material crushing knife 5 and the second raw material dispersing tooth 6; the raw material dispersing frame 3 includes a positioning rod 31, and a plurality of raw material dispersing rods 32 are vertically welded on the positioning rod 31; the raw material crushing knife 5 is a stainless steel blade, and The upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com