Dual-channel rotation inertia coarse powder separator

A coarse powder separator, double-channel technology, applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problem of low impact separation efficiency and achieve the effect of eliminating impact separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

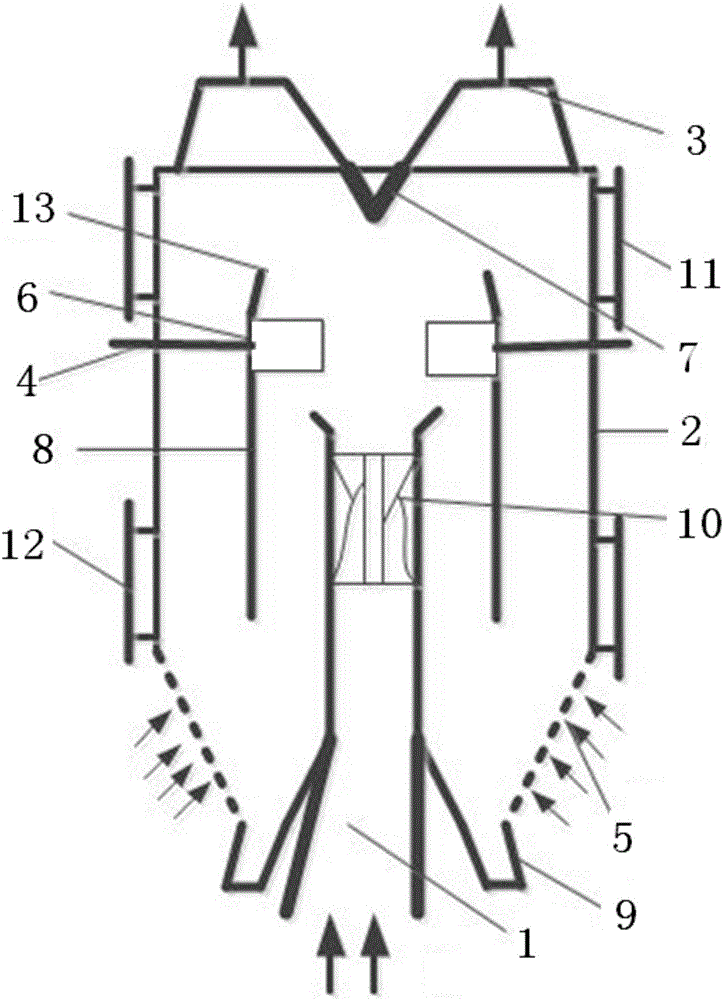

[0037] Method 1: Gas and solids enter through the gas-solid inlet pipe 1, and pass through the impurity removal part 10 in the gas-solid inlet pipe 1. If the vertical rotating blades are used to remove soft substances, the centrifugal force and primary separation are mainly generated. The gas-solid produces a swirling flow field, and the coarse powder spins to the wall of the inner shell 8 to be separated, and is discharged from the powder return pipe 9, and the qualified fine powder goes out from the outlet 3.

[0038] Method 2: Gas and solids enter through the gas-solid inlet pipe 1, and pass through the impurity removal part 10 in the gas-solid inlet pipe 1. If the vertical rotating blades are used to remove soft substances, the centrifugal force and primary separation are mainly generated. Make the gas and solid generate a swirling flow field, and then pass through the small baffle plate 6 to produce two-stage separation. The coarse powder is rotated to the wall of the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com