A mold clamping and moving mechanism of a sheet metal stamping machine

A technology of moving mechanism and punching machine, which is applied in the field of machinery, can solve problems such as insufficient clamping accuracy, manufacturer loss, and shaking, and achieve the effects of firm mold positioning, high degree of automation, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

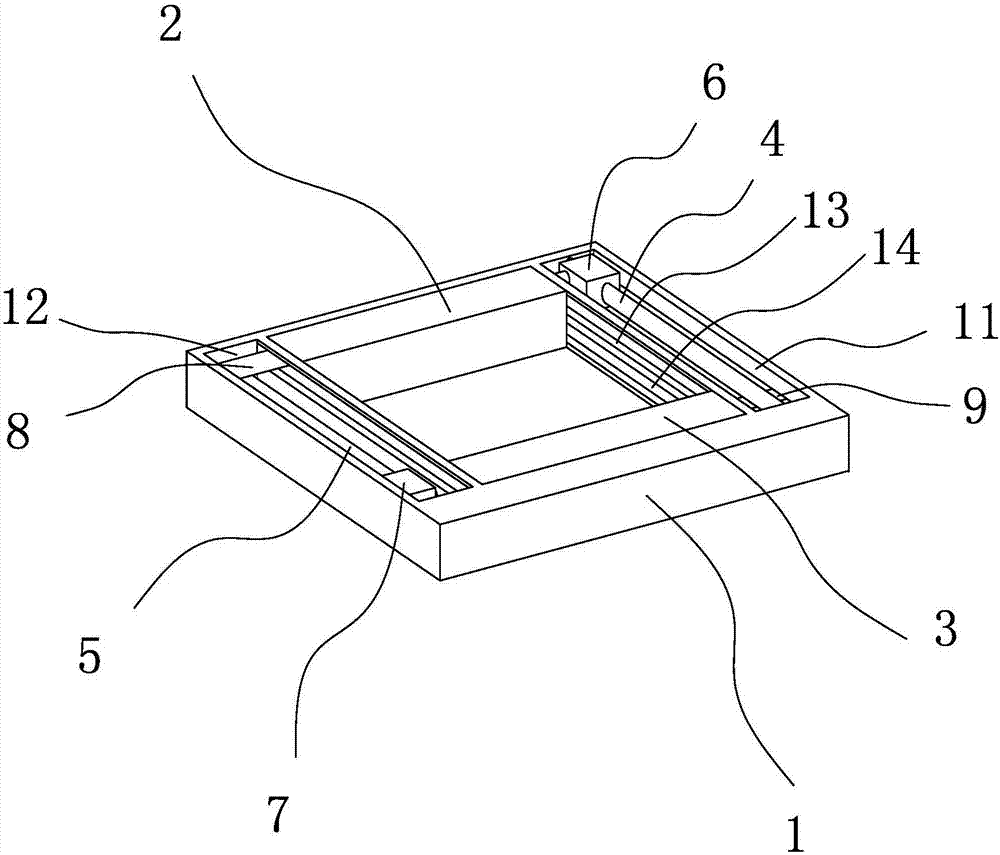

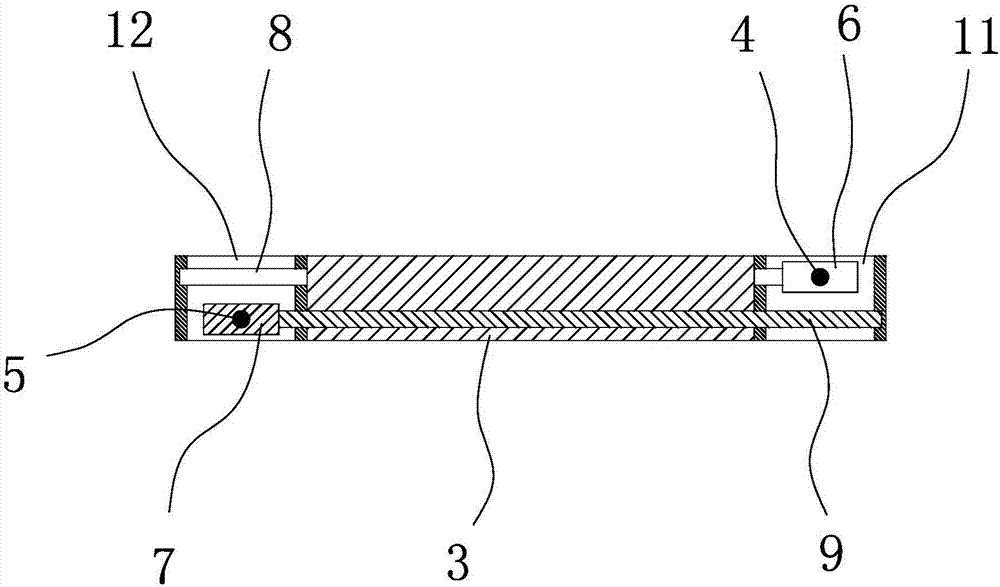

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0019] refer to figure 1 with figure 2 , this embodiment is a mold clamping and moving mechanism of a sheet metal stamping machine, including a rectangular positioning frame 1, on which a first clamping block 2 and a second clamping block 3 for clamping a mold are slidably connected, The first clamping block 2 and the second clamping block 3 are all made into strips, and the first clamping block 2 and the second clamping block 3 are arranged parallel to each other, the sliding direction of the first clamping block 2 and the first The length direction of the clamping block 2 is perpendicular to each other, and the sliding direction of the second clamping block 3 is perpendicular to the length direction of the second clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com