An adjustable terminal for concrete pumping equipment

A concrete pump, adjustable technology, applied in the processing of building materials, construction, building construction, etc., can solve the problems of low efficiency, high energy consumption, low adjustment accuracy, etc., and achieve the effect of high efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

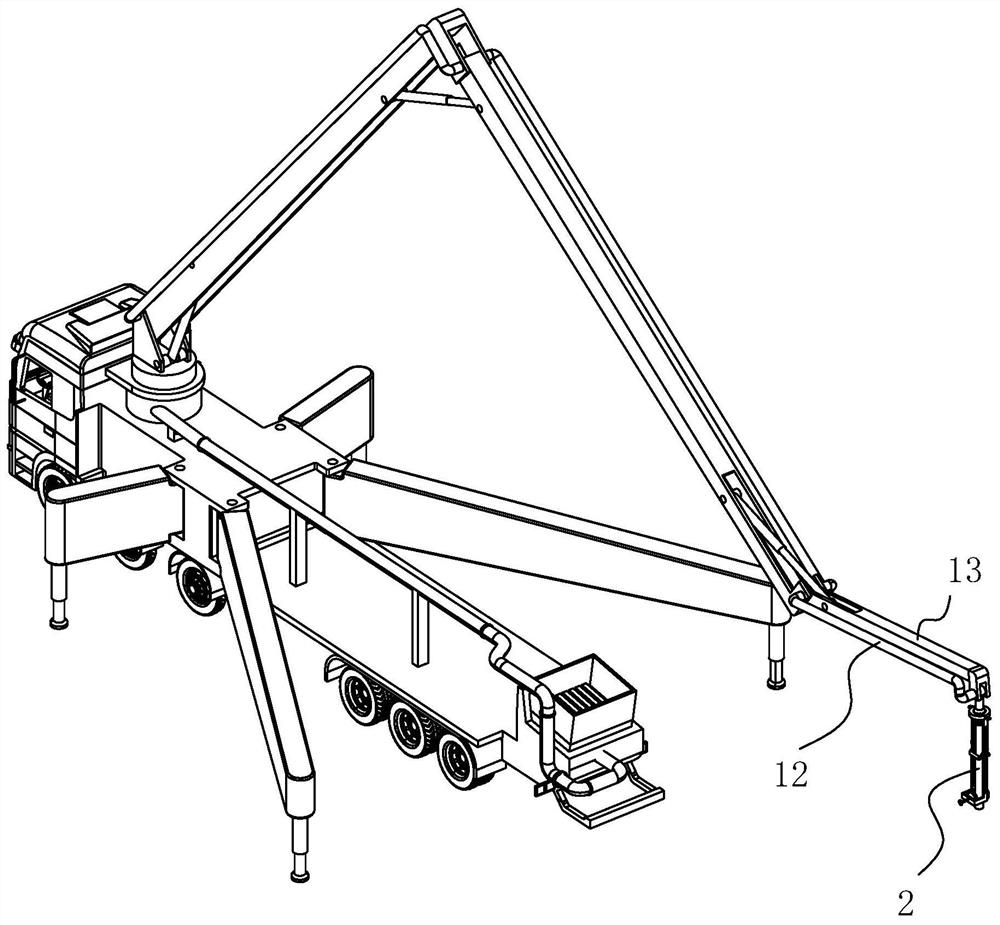

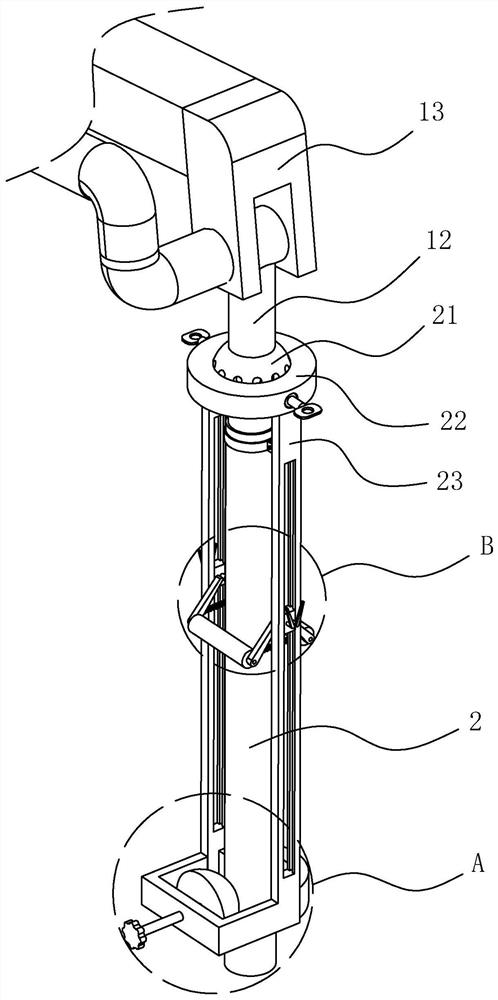

[0039] Adjustable terminal of concrete pumping equipment, reference figure 1 and figure 2 It includes a conveying tube 12, and the delivery tube 12 is made of a hard material. The end outer sleeve of the conveying tube 12 is provided with a hose 2 and is locked by a hug. The bottom outer outer sleeve of the conveying tube 12 is provided with a regulator 21, and the adjustment seat 21 is a cyclic, and the adjustment seat 21 is integrally formed with the conveying tube 12. The outer side wall of the adjustment seat 21 is the spherical surface, and the outer side wall of the adjustment seat 21 is rotatably provided with a regulating ring 22, and the inner side wall of the regulating ring 22 is a spherical surface adapted to the outer side wall of the adjustment seat 21. The strut 23 is fixed to the side of the adjustment ring 22, respectively.

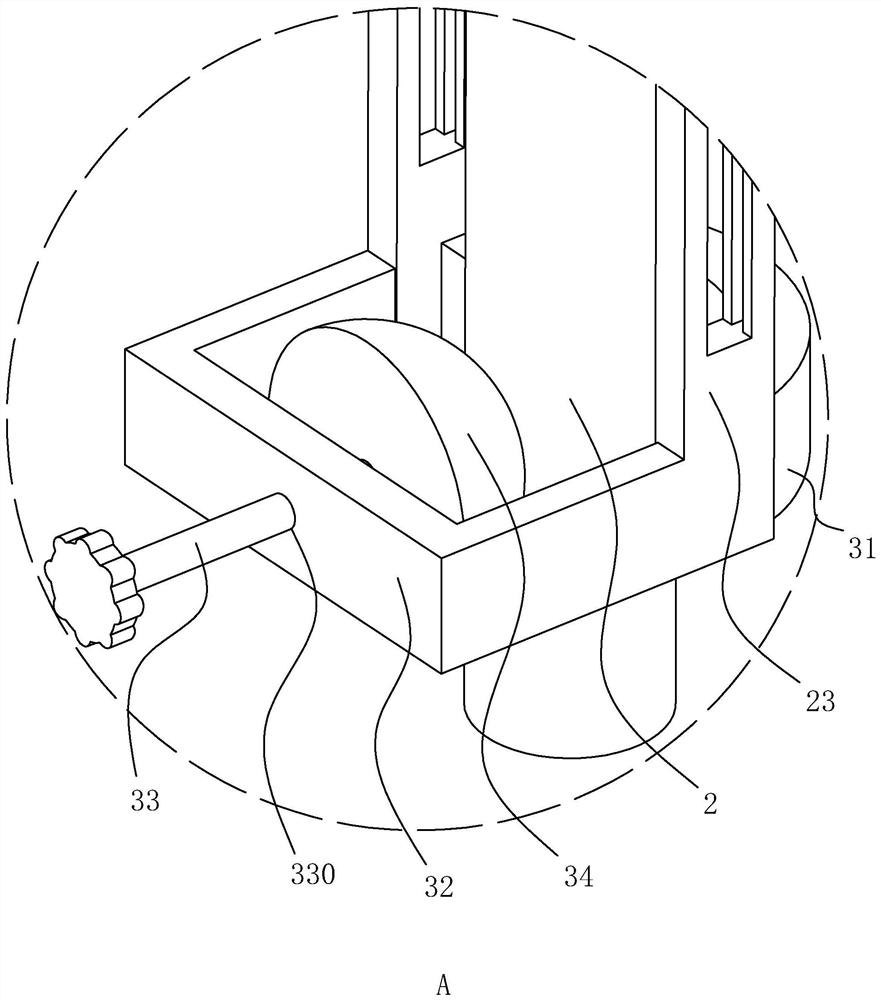

[0040] Refer image 3 , Two rods 23 back to the regulating ring 22 (refer to figure 2 The end welding is fixed to the baffle 31 and the bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com