Electric rice cooker liner negative pressure side machine

A technology of negative pressure car and electric rice cooker, which is applied in the direction of turning equipment, turning equipment, metal processing machinery parts, etc. It can solve the problems of endangering the life safety of operators, easily injuring operators, and personal safety accidents, so as to improve production Efficiency, simple structure and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

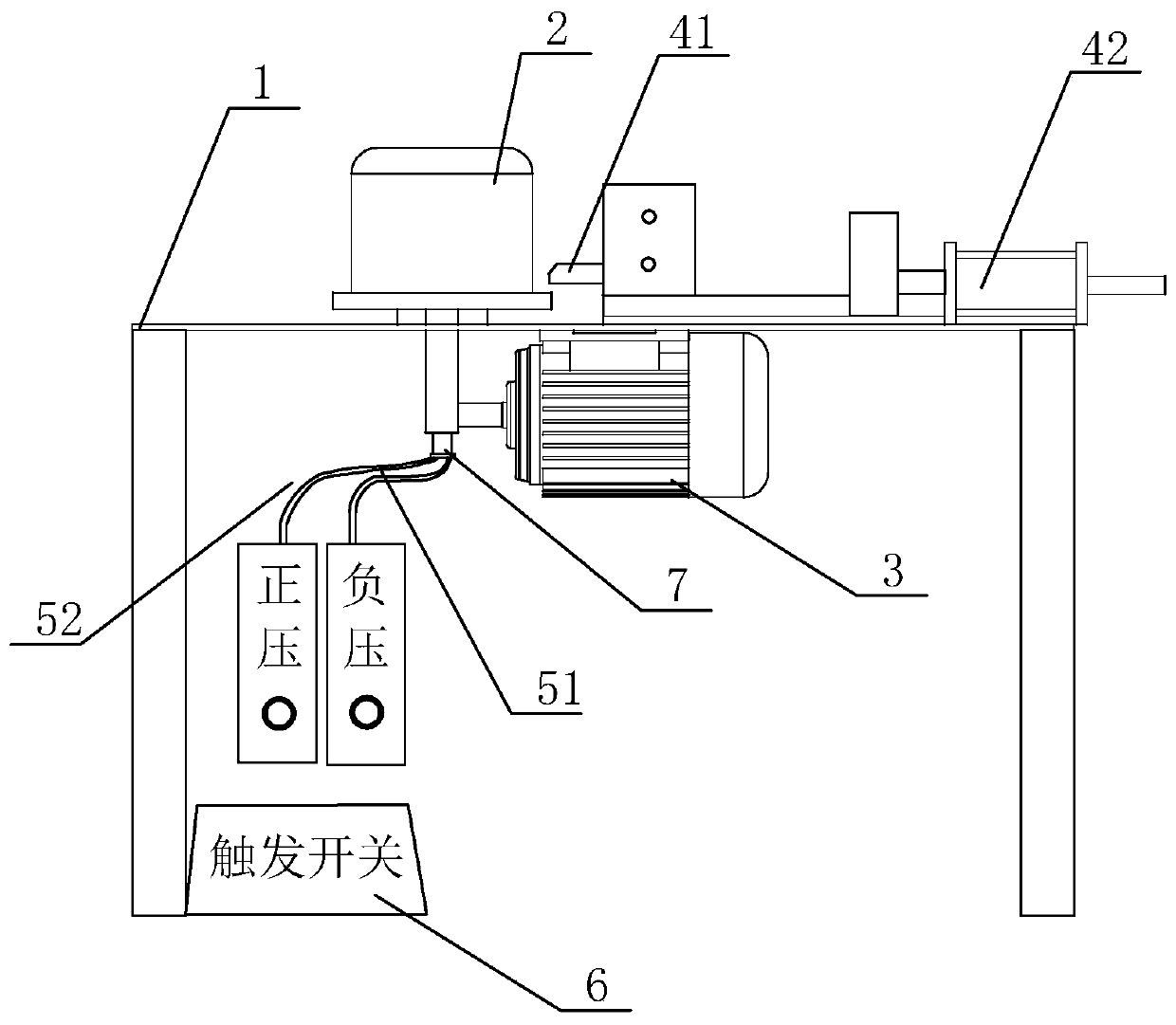

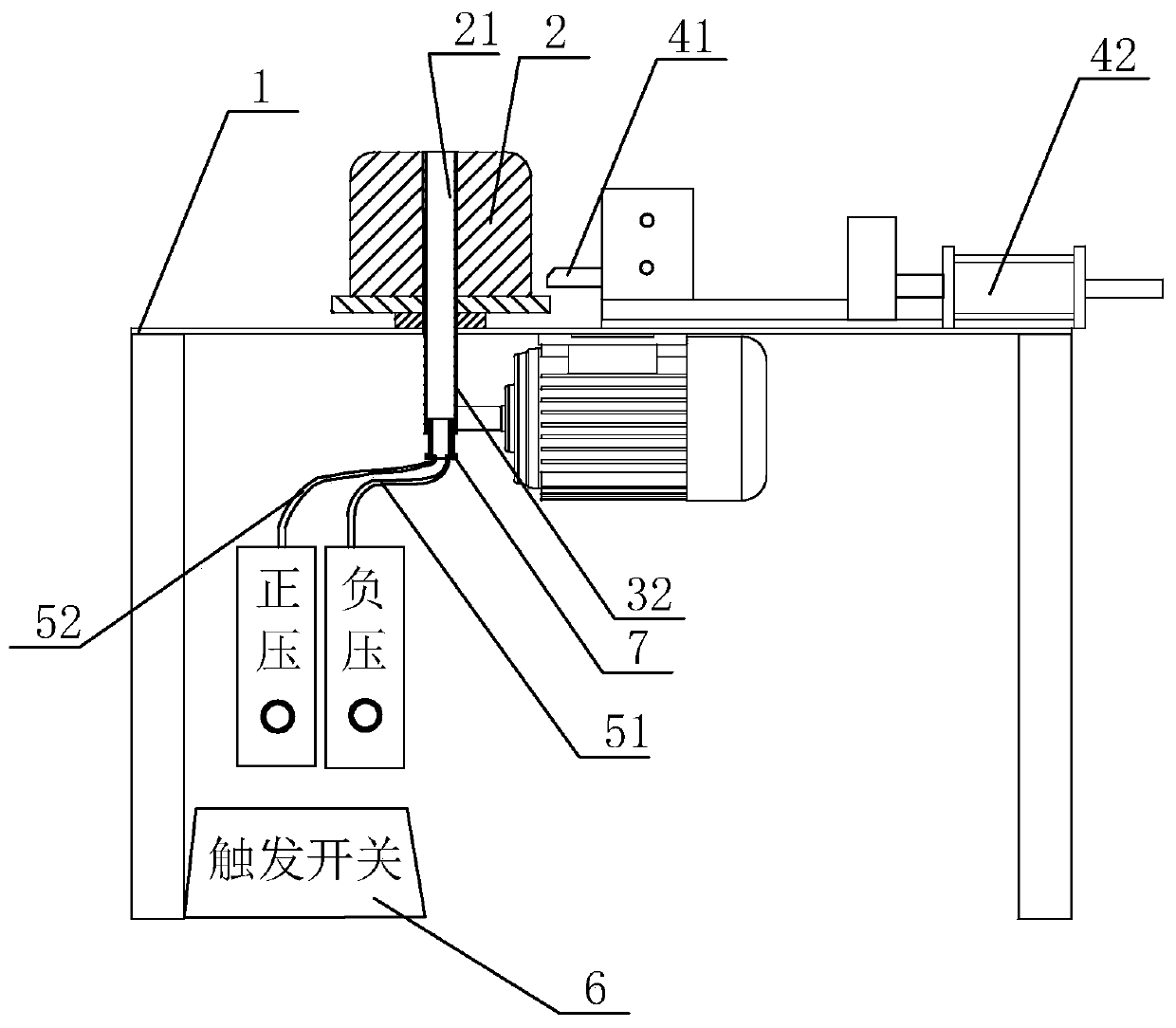

[0040] Such as figure 1 and figure 2As shown, a negative pressure edger for an electric rice cooker liner includes a frame 1, a fixed mold 2 for reverse installation of the inner tank, a rotary drive mechanism for driving the rotation of the fixed mold 2, a trimming device, and a pressure Adjusting device, central control module, delay module and trigger switch 6.

[0041] In order to quickly and stably fix the liner on the fixed mold 2, the pressure regulating device includes a negative pressure mechanism, the negative pressure mechanism includes a negative pressure tube 51, and the middle part of the fixed mold 2 is provided with a pressure regulating channel 21, and one end of the pressure regulating channel 21 is connected to On the outer surface of the top of the fixed mold 2, the pressure regulating channel 21 can also be connected to the inside of the fixed mold 2, and the other end of the pressure regulating channel 21 is connected to the negative pressure tube 51, a...

Embodiment 2

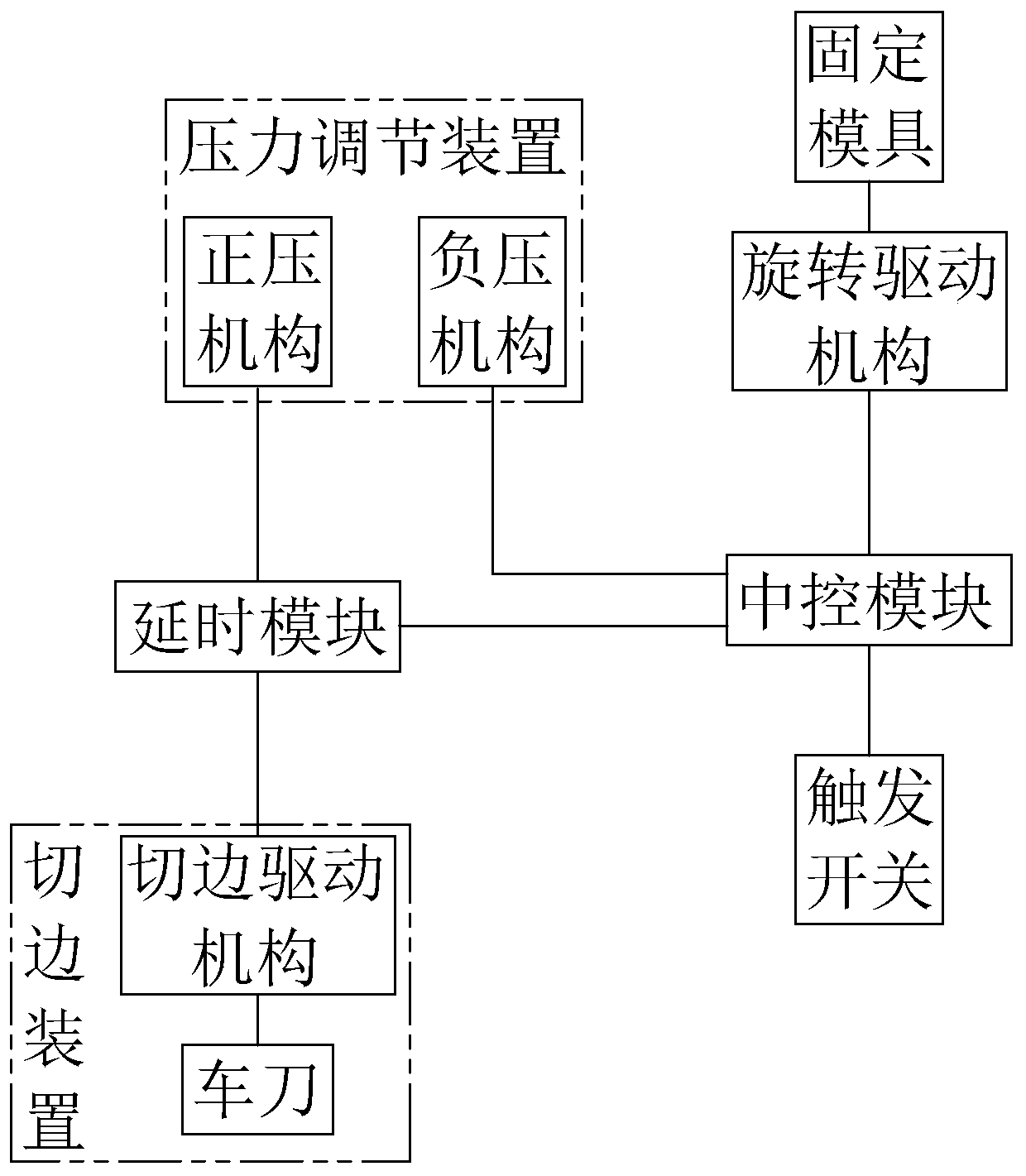

[0057] Such as Figure 4 As shown, a negative pressure edger for an electric rice cooker liner includes a frame 1, a fixed mold 2 for reverse installation of the inner tank, a rotary drive mechanism for driving the rotation of the fixed mold 2, a trimming device, and a pressure Adjusting device, central control module, feedback module and trigger switch 6;

[0058] The pressure regulating device includes a negative pressure mechanism and a positive pressure mechanism, the negative pressure mechanism includes a negative pressure tube 51, and the positive pressure mechanism includes a positive pressure tube 52;

[0059] The trimming device comprises a turning tool 41 and a trimming drive mechanism 42 for promoting the turning tool 41 to advance;

[0060] The trigger switch 6 is connected to the central control module, and the central control module is connected to the rotary drive mechanism 3, the negative pressure mechanism, the positive pressure mechanism and the feedback mod...

Embodiment 3

[0074] In this embodiment, the pressure detection module adopts an air pressure detection module, and the touch detection module in Embodiment 2 is replaced by the air pressure detection module. Because the touch detection module may cause false feedback signals due to false touches, and changes in air pressure can minimize accidental external causes.

[0075] This embodiment is similar to the embodiment 2. It is detected whether the liner is fully fastened on the surface of the fixed mold by detecting the air pressure in the pressure regulating channel-negative pressure tube. When the liner is fully fastened on the surface of the fixed mold, the liner seals the pressure regulating channel, causing the air pressure in the pressure regulating channel-negative pressure tube to drop suddenly. By detecting the change value of this pressure, it is estimated whether the liner has been fully fastened. on the mold surface.

[0076] The air pressure detection module in this embodiment...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap