Root positioning mechanism for T root blade profile detection of steam turbine

A technology for positioning mechanisms and steam turbines, applied to workpiece clamping devices, manufacturing tools, etc., can solve problems affecting detection accuracy and unreliable blade root positioning and clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

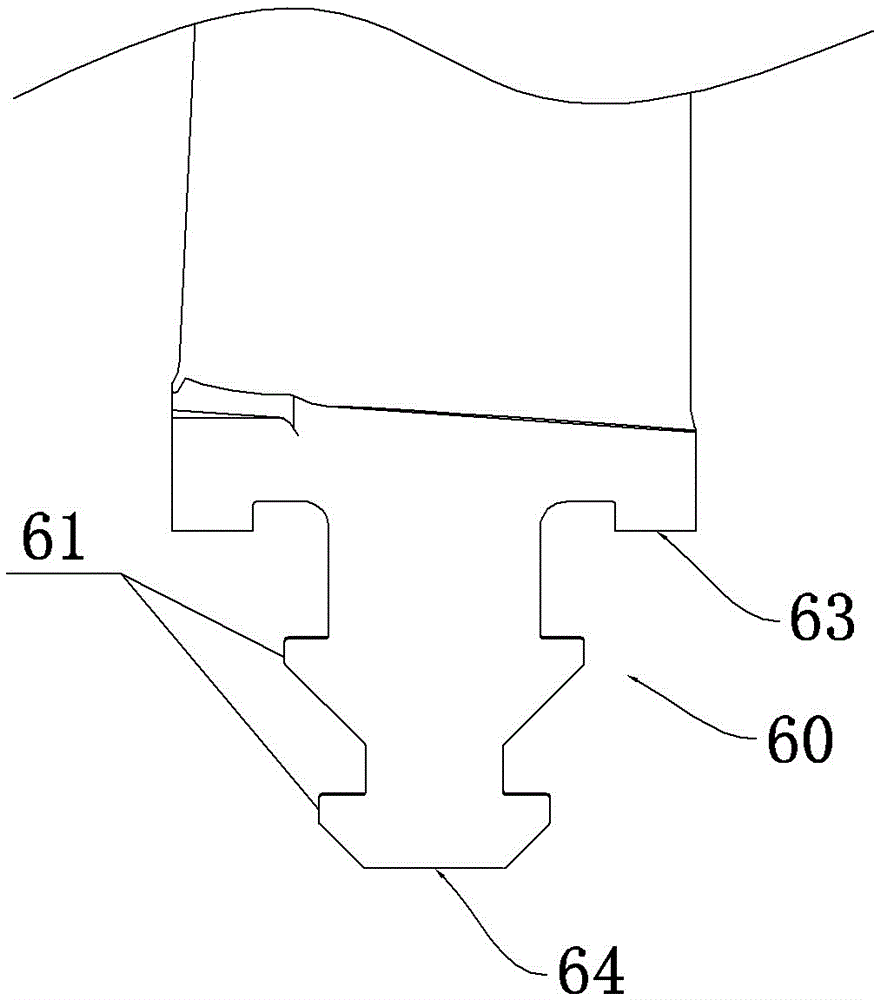

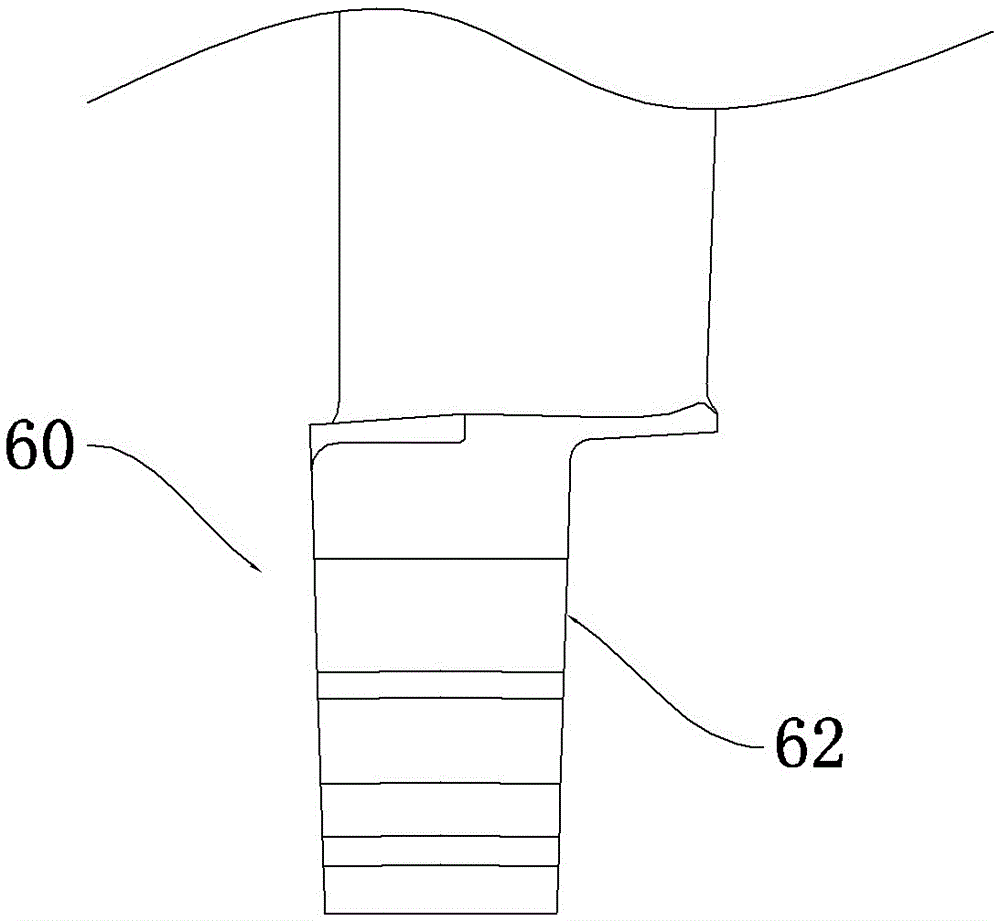

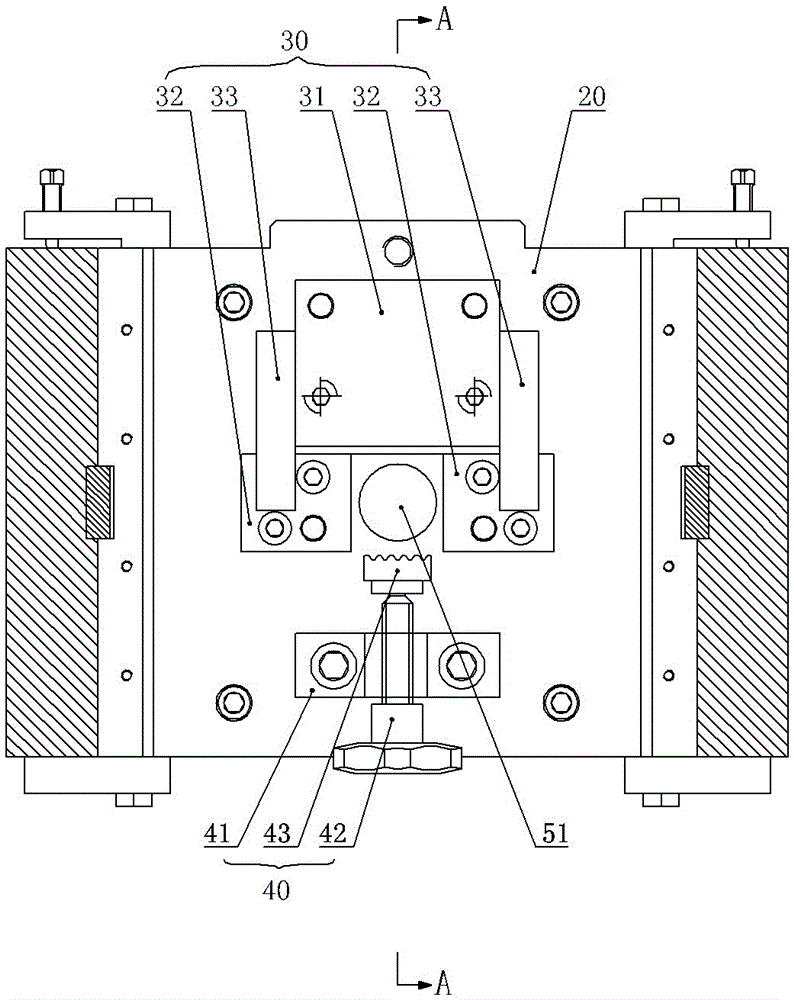

[0022] See image 3 and Figure 4 , the mechanism of the present invention includes a surface measuring tool base plate 10, a positioning base plate 20 is fixedly installed on the profile measuring tool base plate 10, a blade root positioning assembly 30 is fixedly installed on the positioning base plate 20, and the blade root positioning assembly 30 includes a positioning seat 31 and a diameter To the positioning seat 32, the two ends of the front side of the positioning seat 31 are respectively provided with mutually symmetrical radial positioning seats 32, the positioning seat 31 and the two radial positioning seats 32 are in a concave structure with an open front side, and the T-shaped blade root 60 is positioned in the concave structure and two radial positioning seats 32 are positioned on the shoulder upper surface 61 of the T-shaped blade root. A blade root radial tightening mechanism 40 is provided on the side, and the blade root radial tightening mechanism 40 tighten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com