Automatic buckling and pressing type spraying aerosol can

A technology of automatic spraying and aerosol cans, applied in the direction of liquid distribution, etc., can solve the problems of low efficiency, high spraying cost, inconvenient operation, etc., and achieve the effect of reducing labor intensity, good spraying effect and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

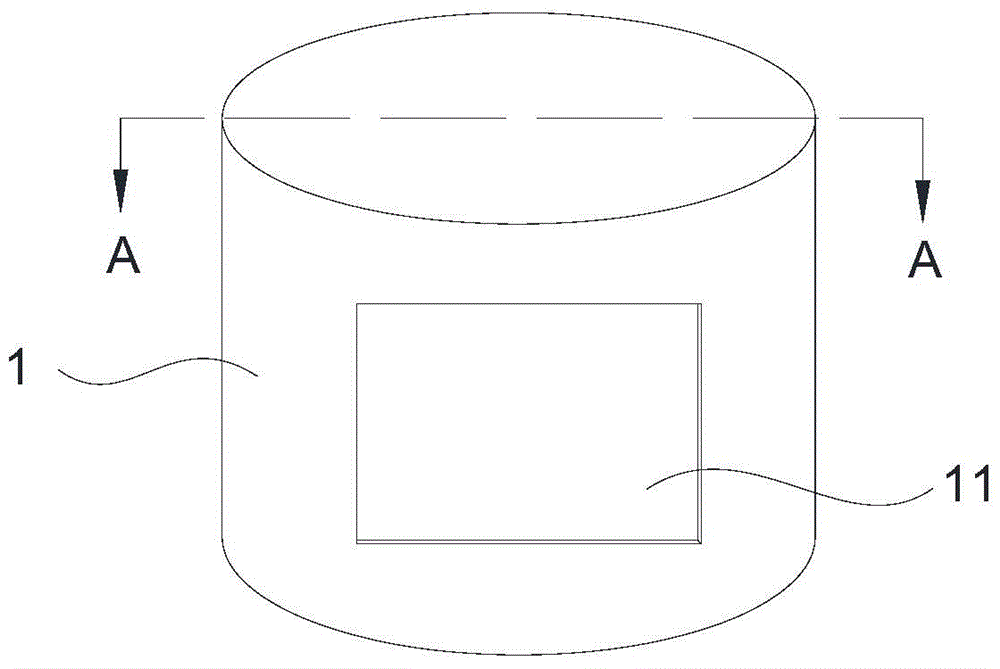

[0018] Such as Figure 1-4 As shown, the buckle type automatic spraying aerosol can includes a gland 1 and a tank body 2 . One end of the tank body 2 is formed with a valve cover 21, and the top of the valve cover 21 is provided with a spray head 23, and the aerosol can sprays aerosol by pressing the spray head 23. The gland 1 can be sleeved on the valve cover 21 of the tank body 2 .

[0019] The side of the gland 1 is provided with an injection port 11 corresponding to the spray hole 24 on the spray head 23 . The gland 1 is sleeved on the valve cover 21 , and when the spray head 23 is pressed, the aerosol in the tank body 2 can be sprayed out from the injection port 11 .

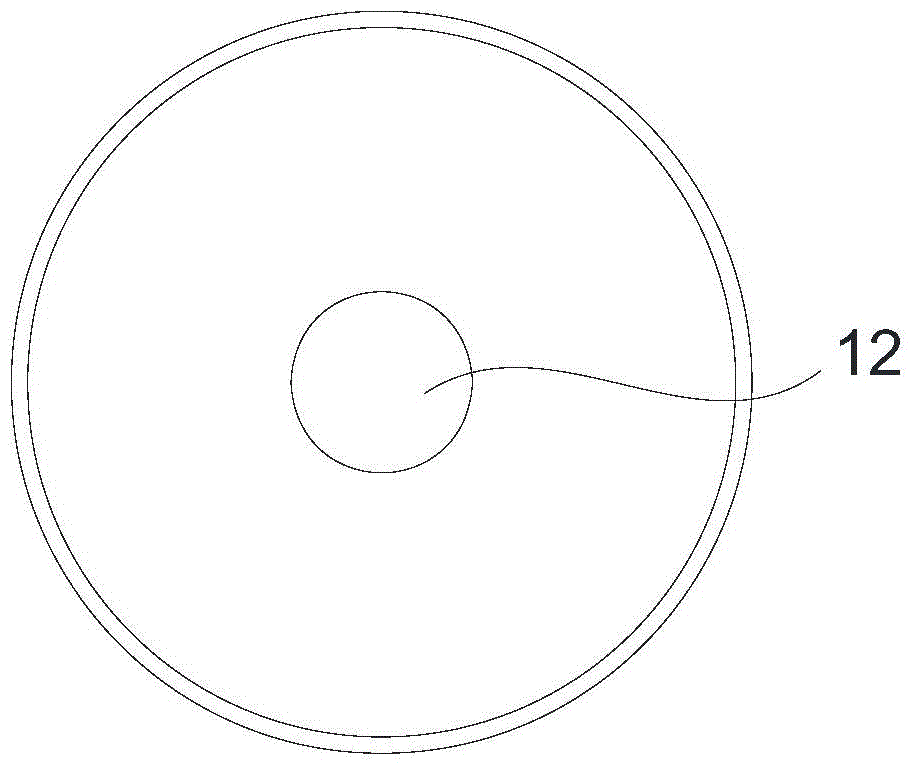

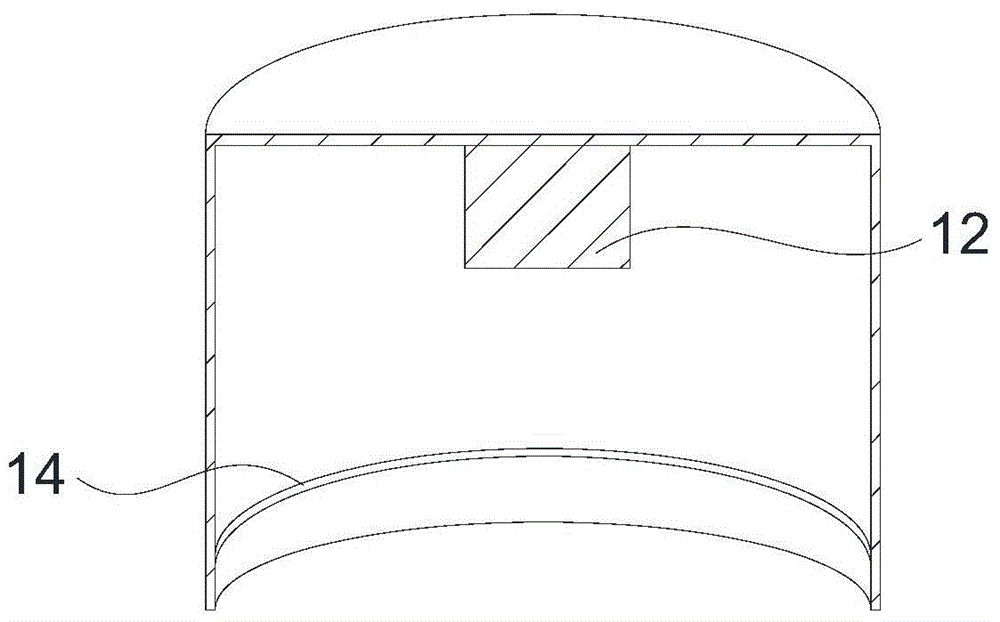

[0020] The bottom of the gland 1 is provided with a solid pillar 12 corresponding to the pressing end of the spray head 23 , and the inner wall is provided with a slot, which is a groove 14 surrounding the inner wall of the gland 1 .

[0021] The outer wall of the valve cover 21 of the tank body 2 is pro...

Embodiment 2

[0024] Such as Figure 5 , 6 As shown, the difference between this embodiment and the buckle-type automatic spraying aerosol can of Embodiment 1 is that the inner wall of the gland 1 of the buckle-type automatic spraying aerosol can of this embodiment is provided with a card slot 15 and a groove 16 ; Valve cover 21 is provided with a convex ring 26 .

[0025] When the protruding ring 26 and the locking groove 15 are buckled and fixed, the top of the pillar 12 is connected to the pressing end of the spray head 23, and the spray head 23 is in a closed state. When the protruding ring 25 is engaged with the groove 16, the strut 12 compresses the spray head 23 to be in a state of maximum compression.

Embodiment 3

[0027] Such as Figure 7 As shown, the difference between this embodiment and the buckle-type automatic spraying aerosol can of Embodiment 2 is that a limiting groove 17 for fitting the protruding ring 25 is also provided between the slot 15 and the groove 16 of the gland 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com