Assembly car of conveyor line

A technology for assembling vehicles and conveyor lines, applied in conveyors, mechanical conveyors, transportation and packaging, etc., which can solve problems such as low work efficiency, inconvenient operation, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

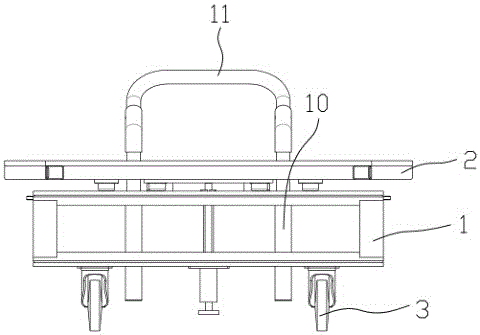

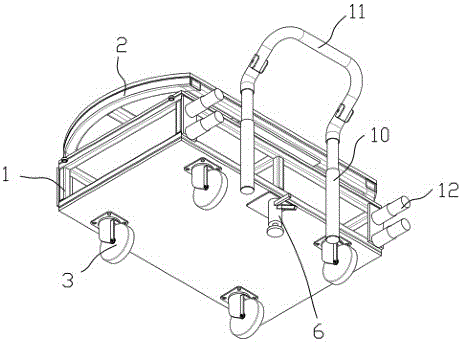

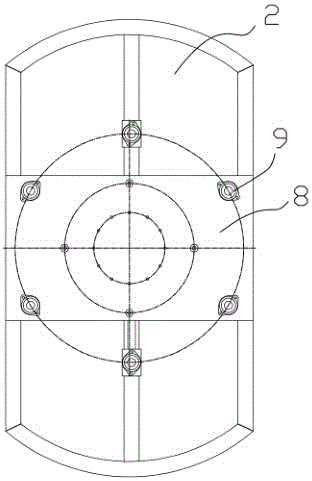

[0011] An assembly vehicle for a conveyor line, such as Figure 1 to Figure 5 As shown, it includes a lower support platform 1 and an upper support platform 2 that can rotate relative to the lower support platform 1. The bottom of the lower support platform 1 is provided with a roller 3 that matches the conveying track, and the bottom surface of the upper support platform 2 is provided with A plurality of positioning grooves, the upper surface of the lower support platform 1 is provided with a plurality of stoppers 13 that match the positioning grooves on the bottom surface of the upper support platform 2, and the stoppers 13 include The spring on the surface, the spring top is connected with the spherical head 4 that matches with the positioning groove, under the natural state of the spring, the spherical head 4 on it is inserted in the positioning groove of the corresponding upper support platform 2 bottom surface, and the lower support platform 1 and the upper support platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com