A wheel jacking mechanism applied to high-speed rail wheel production line

A jacking mechanism and production line technology, applied in the direction of lifting devices, etc., can solve the problems of wheel conveying equipment and grabbing machinery mechanical impact, difficulty in safe and stable operation, and reduced service life, so as to improve service life, reduce mechanical impact damage, Optimizing the performance of crawling operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

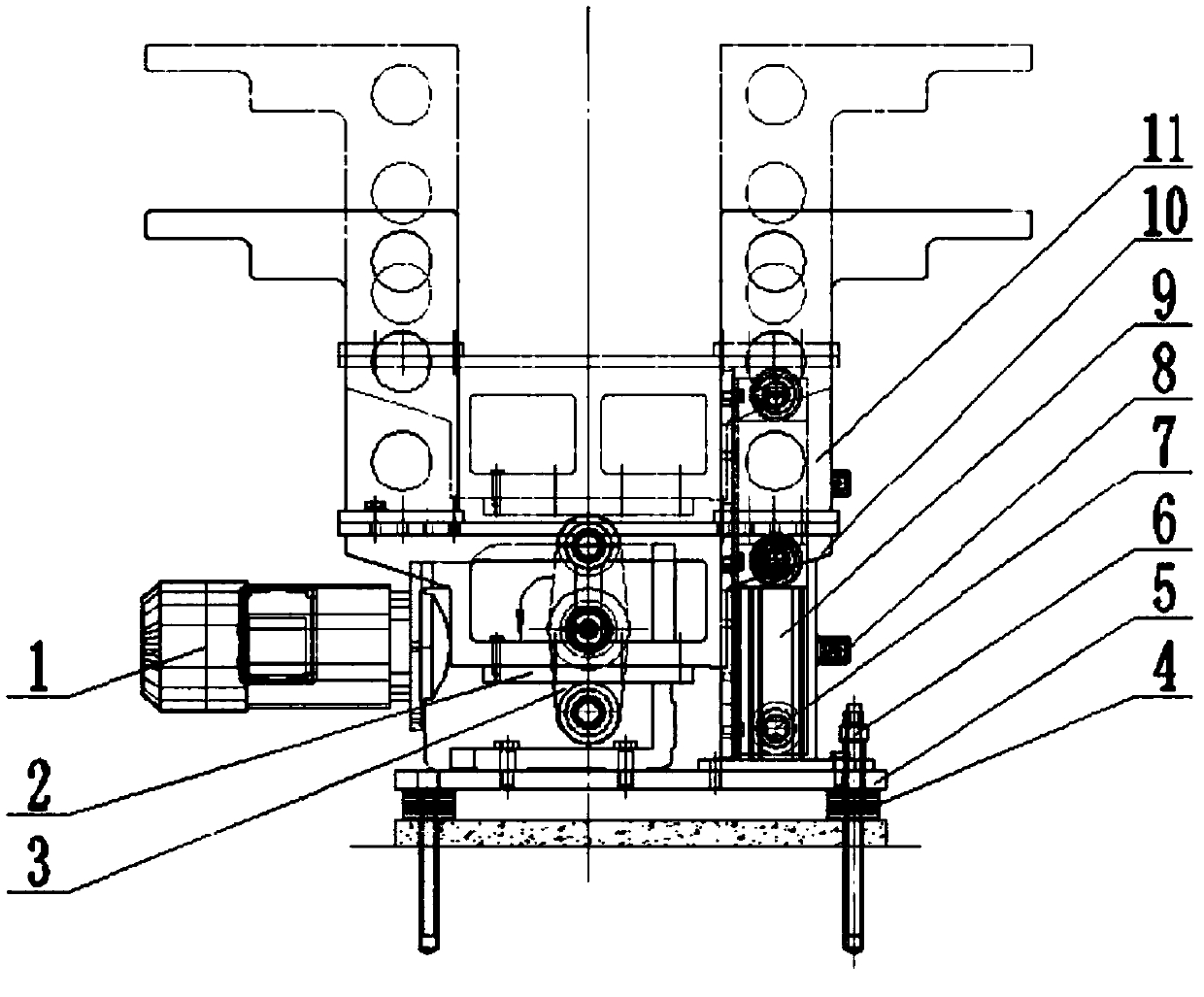

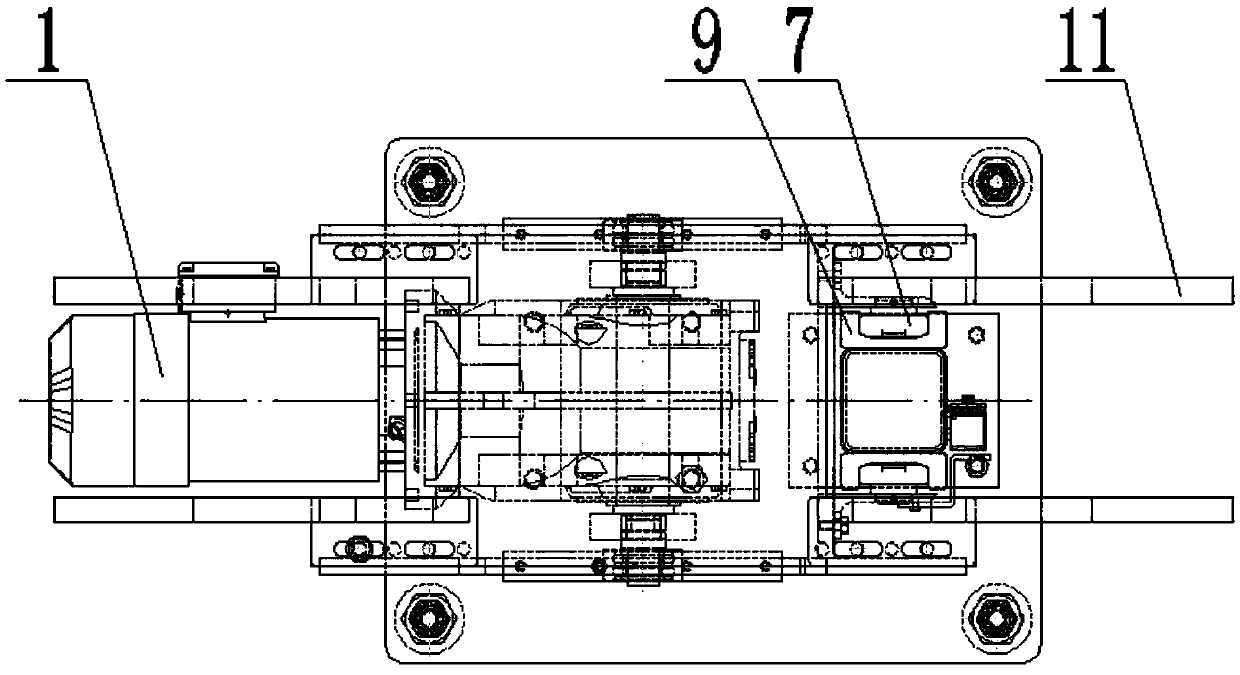

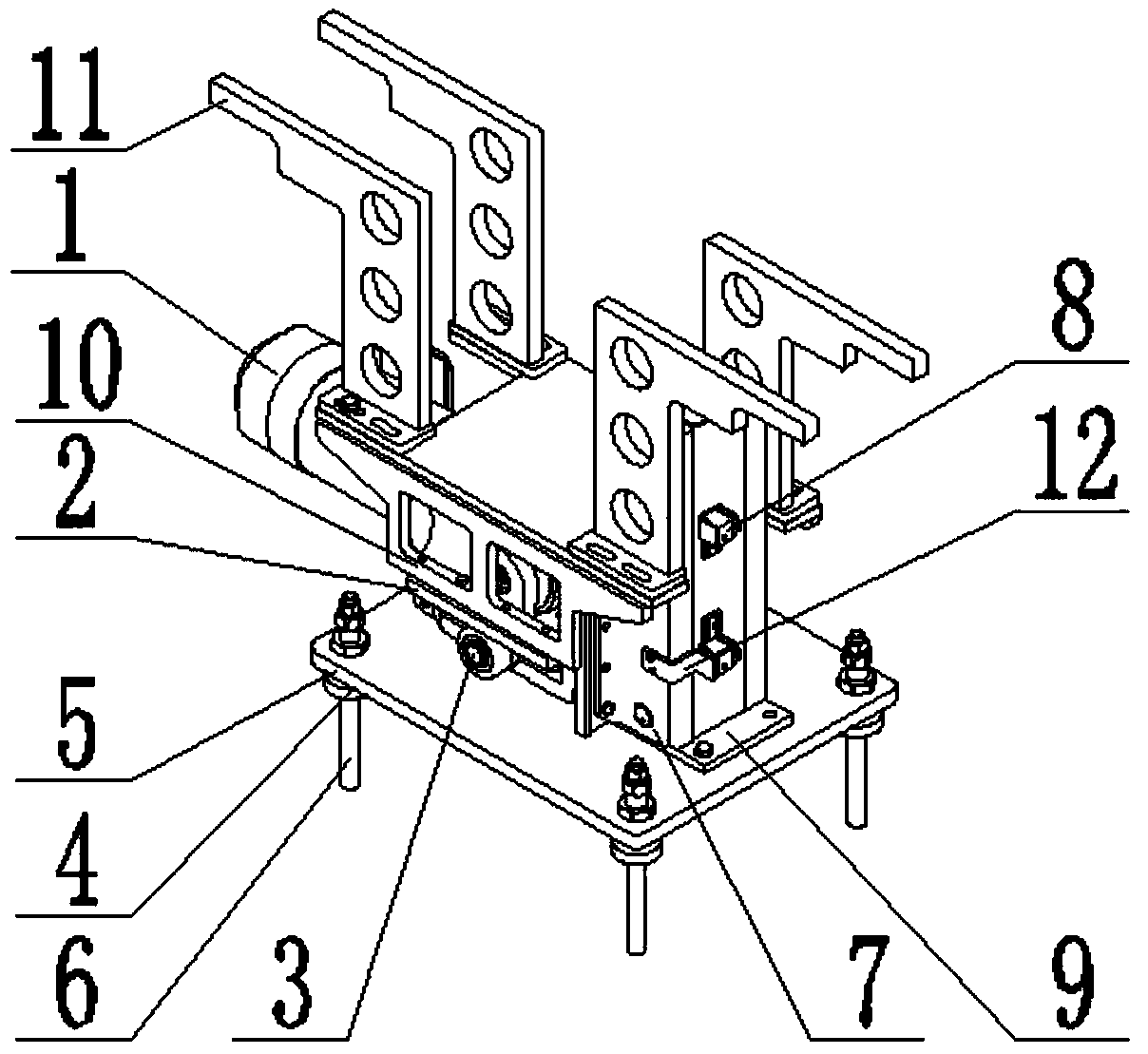

[0025] Such as Figure 1-3 As shown, a wheel jacking mechanism applied to a high-speed rail wheel production line in this embodiment includes a metal shock absorber 4, a mounting base plate 5 and a movable frame 10, and the mounting base plate 5 and the movable frame 10 are all processed by steel plates. The above-mentioned metal shock absorber 4 is fixed on the lower side of the installation base plate 5 by bolts 6, and a guide groove device 9 is provided on the installation base plate 5, and a sensor 8 is provided on the side of the above-mentioned guide groove device 9, and the guide groove device 9 is installed There is a movable frame 10, four support forks 11 are fixed on the upper part of the movable frame 10, and the support forks 11 are made of steel plates with process holes on them; the lower parts of the two sides of the movable frame 10 are respectively fixed with track plates 2. The material of the track plate 2 is flat steel. The pulley eccentric shaft 3 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com