Method for improving oil absorption value by treating white carbon black through alcohols

A technology of white carbon black and oil absorption value, applied in the field of white carbon black preparation, can solve problems such as increasing production energy consumption, and achieve the effects of reducing energy and simplifying the production operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

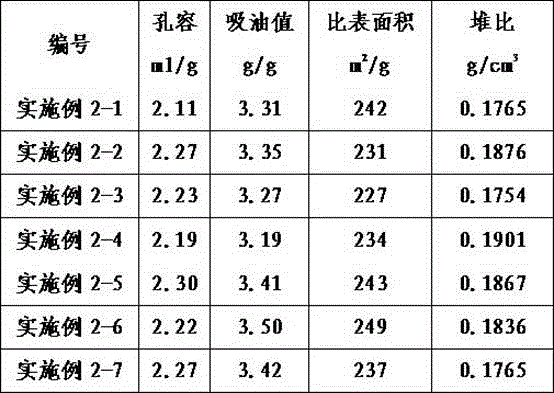

Examples

Embodiment 1

[0018] 1000 grams of pure water were injected into the reaction vessel. Get silicon dioxide concentration and be 700 grams of water glass solutions of 15 wt%, concentration is 300 grams of sulfuric acid of 20 wt%, add reaction vessel simultaneously; to 90°C. After co-current was completed, the reaction mixture was aged at 80° C. for 2 hours, the pH value of the system was adjusted to 2, and aged for another 3 hours. The obtained slurry is washed, and press-filtered into a wet filter cake with a solid content of 40%. According to the weight ratio of isobutanol: water is 1:1, add isobutanol and mix with the wet filter cake. The mixture is dispersed with an emulsifier for 30 minutes, and the speed of the emulsifier is 4000 rpm. After the dispersion is completed, the resulting slurry is spray-dried, and then pulverized by airflow to obtain a product with a particle size of 3-5 microns.

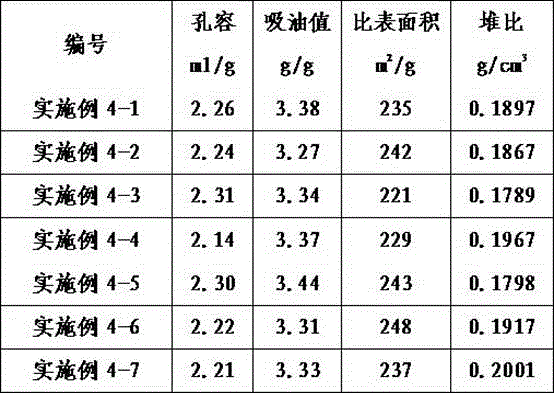

[0019] The physical and chemical properties of seven parallel samples are shown in Table 1:...

Embodiment 2

[0023] 1000 grams of pure water were injected into the reaction vessel. Get silicon dioxide concentration and be 525 grams of water glass solution of 20 wt%, concentration is 600 grams of sulfuric acid of 10 wt%, add reaction vessel simultaneously; to 90°C. After co-current was completed, the reaction mixture was aged at 80° C. for 5 hours, the pH value of the system was adjusted to 3, and aged for another 1 hour. Wash the obtained slurry, press filter to form a wet filter cake with a solid content of 30%. According to the weight ratio n-butanol: water 0.5:1, add n-butanol and mix with the wet filter cake. The mixture is dispersed with an emulsifier for 30 minutes, and the speed of the emulsifier is 9000 rpm. After the dispersion is completed, the resulting slurry is spray-dried, and then pulverized by airflow to obtain a product with a particle size of 3-5 microns.

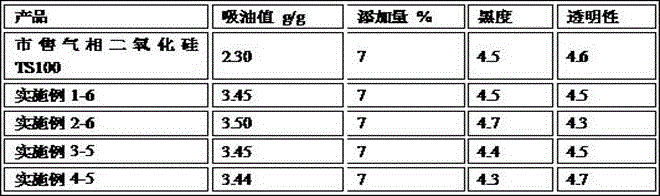

[0024] The physical and chemical properties of seven parallel samples are shown in Table 2:

[0025] Table...

Embodiment 3

[0028] 1000 grams of pure water were injected into the reaction vessel. Get silicon dioxide concentration and be that 10 wt% water glass solution 1050 grams, concentration is 200 grams of sulfuric acid of 30 wt%, add reaction vessel simultaneously; The co-current pH value is 10, and the co-current reaction time is 1 hour, and the co-current reaction temperature to 70°C. After co-current was completed, the reaction mixture was aged at 60° C. for 4 hours, the pH value of the system was adjusted to 4, and aged for another 1 hour. The obtained slurry is washed, and press-filtered into a wet filter cake with a solid content of 40%. According to the weight ratio of isopropanol: water is 2:1, add isopropanol and mix with the wet filter cake. The mixture is dispersed with an emulsifier for 30 minutes, and the speed of the emulsifier is 8000 rpm. After the dispersion is completed, the resulting slurry is spray-dried, and then pulverized by airflow to obtain a product with a particle ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap