A microbubble circulation reaction system

A technology of loop reaction and loop reactor, applied in the direction of mechanical oscillation water/sewage treatment, etc., can solve the problems of reduced gas-liquid interface area, discounted treatment effect, small liquid drag, etc., achieve low energy consumption and improve treatment effect , the effect of low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will now be further described in conjunction with the drawings and embodiments.

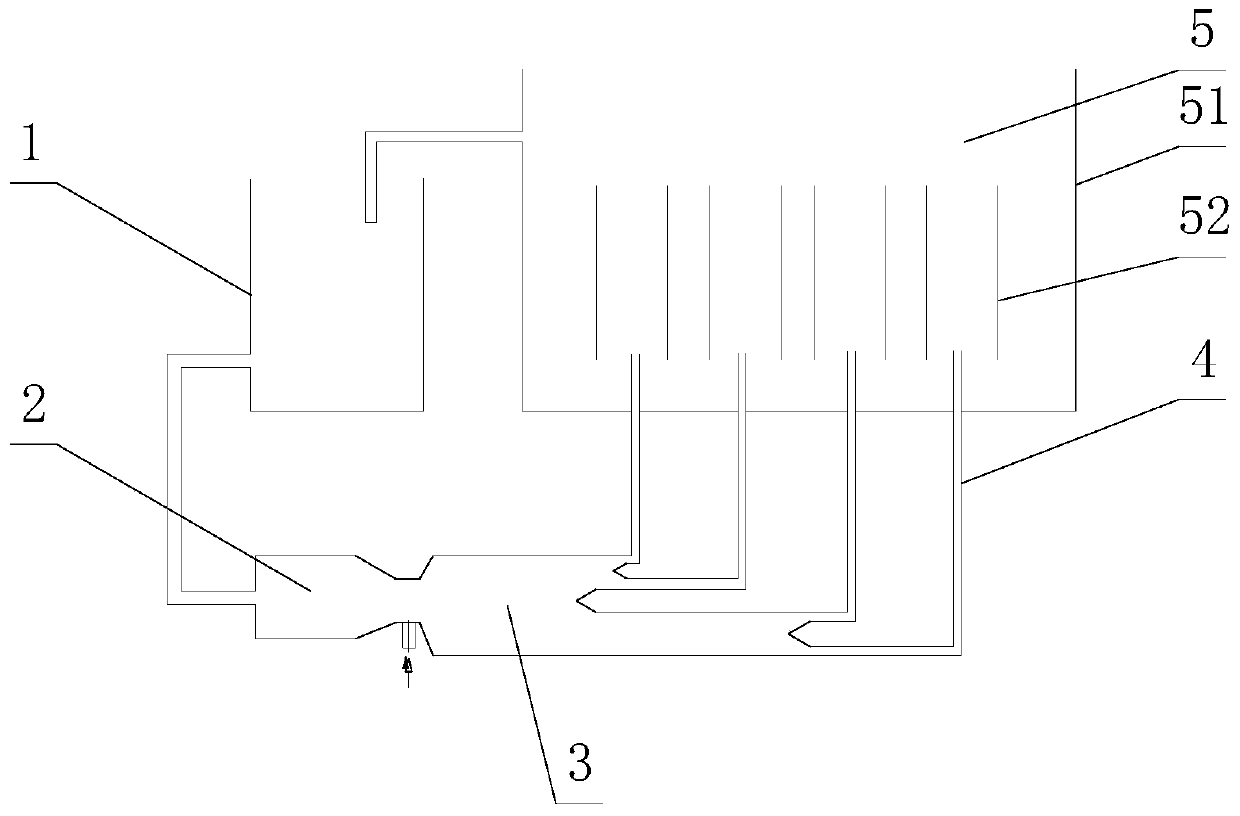

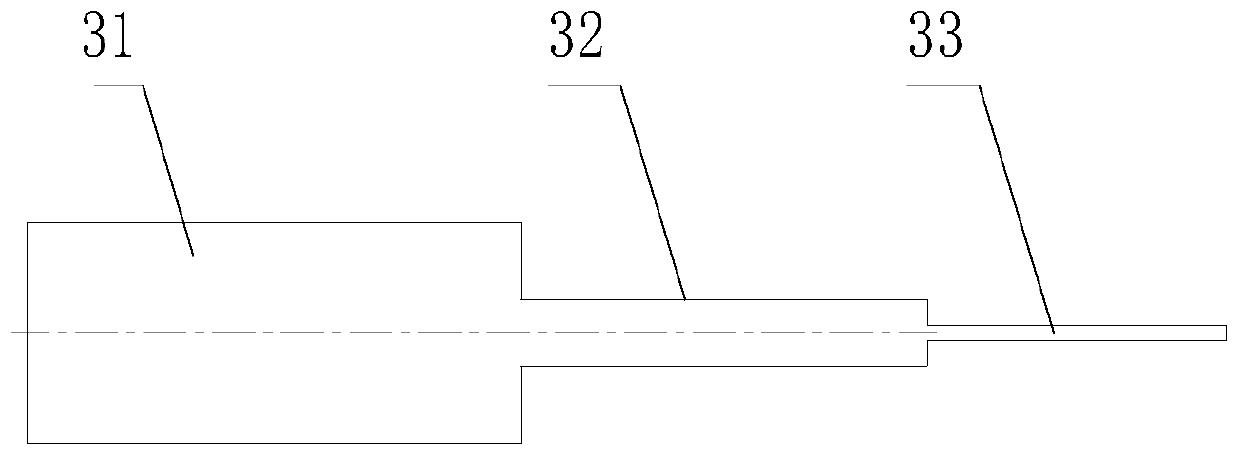

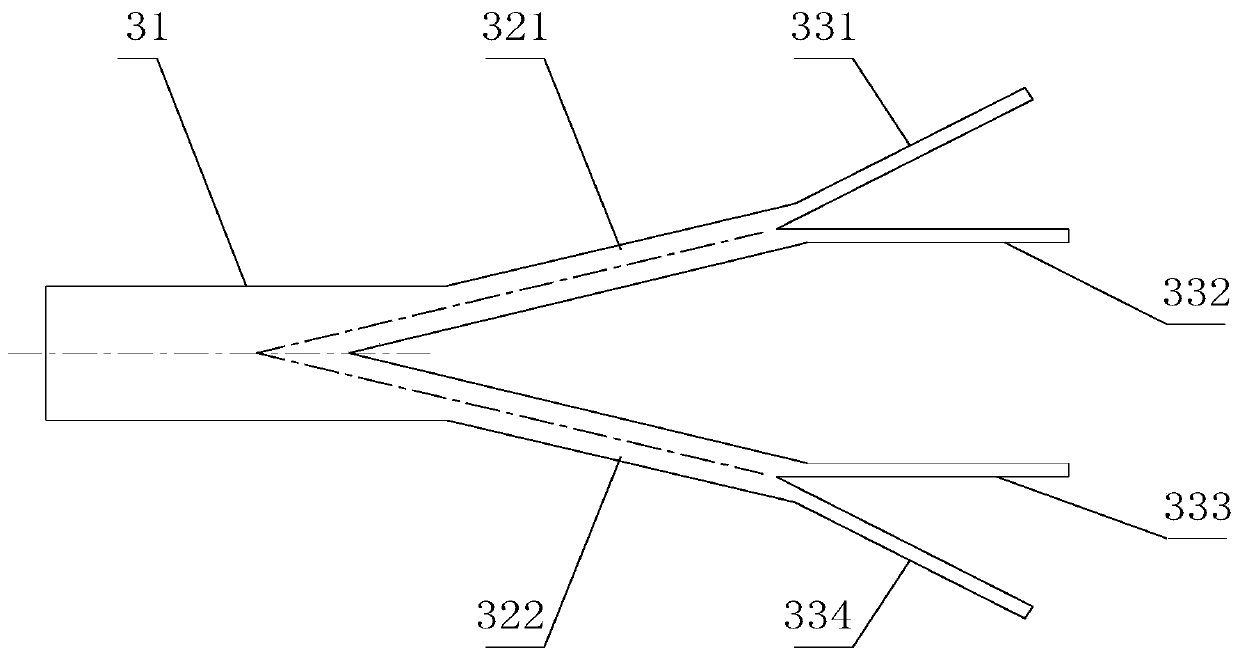

[0030] Depend on figure 1 It can be seen that the microbubble circulation reaction system of this embodiment comprises a water tank 1 , a liquid inlet pump 2 , a circulation reactor 5 , a Y-shaped gas-liquid mixer 3 and a draft tube 4 in combination. Wherein, the top of the water tank 1 is open, and a water outlet is provided at the bottom of the water tank 1, and the water outlet of the water tank 1 communicates with the liquid inlet of the Y-type gas-liquid mixer 3 through the liquid inlet pump 2 installed on the pipeline, that is, Y The inlet of the Y-type gas-liquid mixer 3 is communicated with the outlet of the liquid inlet pump 2 and the inlet pump installed on the pipeline through a three-way pipe, and the outlet of the Y-type gas-liquid mixer 3 is connected through the guide tube 4 and the loop reactor 5. The bottom end of the flow t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com