Preparation method of nanoscale 3-aminophenol formaldehyde resin particles based on microfluidic technology

A microfluidic technology and formaldehyde resin technology, which is applied in the field of preparation of nano-scale 3-aminophenol formaldehyde resin particles, can solve the problems of low efficiency heat and mass transfer, rough process parameter control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

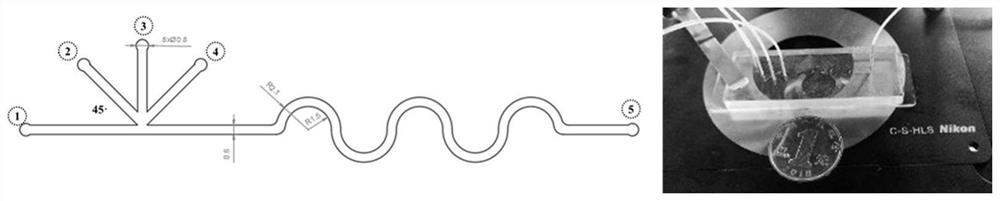

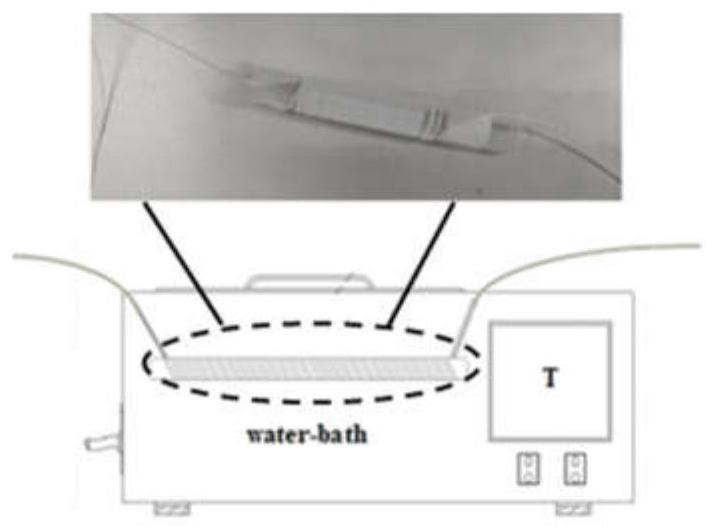

[0027] 1) Preparation of microreactor: The PDMS chip is prepared by soft lithography technology. The cross-section of the chip channel is uniformly square, with a side length of 600 μm; the included angle of the raw material adding channel is 45°; the meandering channel has an outer diameter of 2.1 mm and an inner diameter of 1.5 semi-circular channels, the total length is 35mm; the heating pipe is made of PTFE tube, the inner diameter of the tube is 0.6mm, the length of the tube is 15.9m, and the length of the part of the tube wound on the glass rod with an outer diameter of 10mm is 15.1m; one end of the spiral structure PTFE tube and the chip Outlet connection, one end inserted into the Erlenmeyer flask;

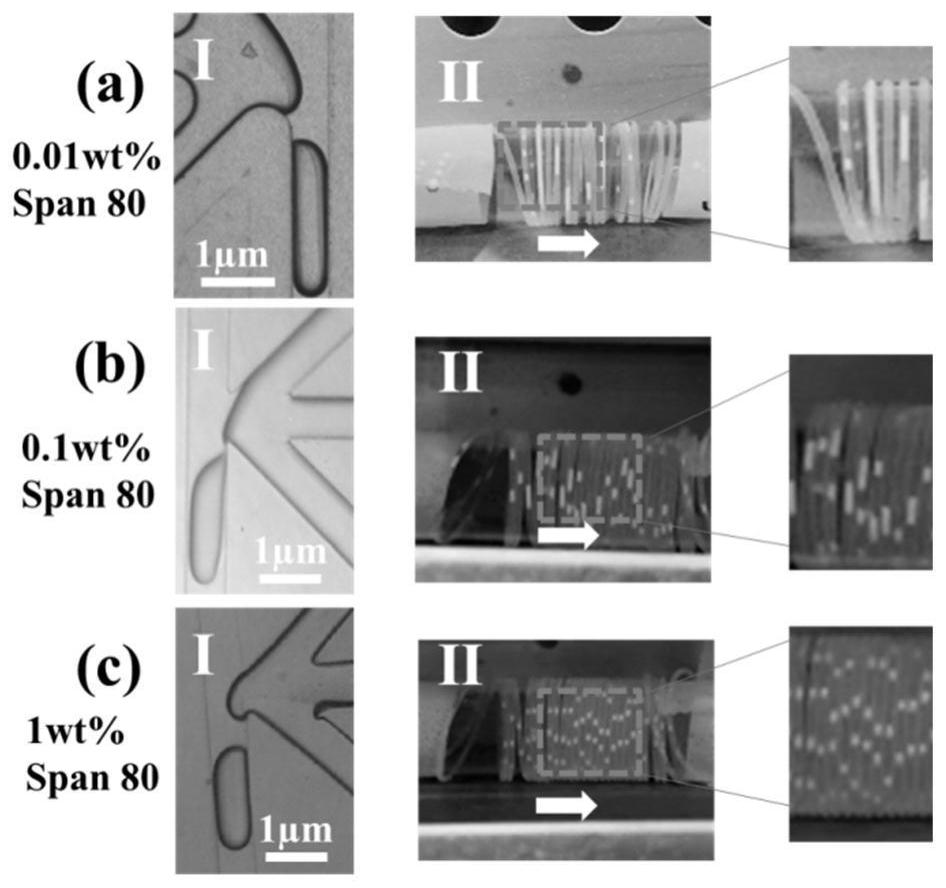

[0028] 2) Take 0.35g of 3-aminophenol, 0.75g of formaldehyde, and 0.52g of ammonia water and dissolve them in 10mL of water respectively. After fully dissolving, inhale into a 10mL syringe, and fix the syringe on the digital control micro pump; s Simethicone, inhale into a...

Embodiment 2

[0033] 1) Preparation of microreactor: The PDMS chip is prepared by soft lithography technology. The cross-section of the chip channel is uniformly square, with a side length of 600 μm; the included angle of the raw material adding channel is 45°; the meandering channel has an outer diameter of 2.1 mm and an inner diameter of 1.5 semi-circular channels, the total length is 35mm; the heating pipe is made of PTFE tube, the inner diameter of the tube is 0.6mm, the length of the tube is 15.9m, and the length of the part of the tube wound on the glass rod with an outer diameter of 10mm is 15.1m; one end of the spiral structure PTFE tube and the chip Outlet connection, one end inserted into the Erlenmeyer flask;

[0034] 2) Take 0.35g of 3-aminophenol, 0.75g of formaldehyde, and 0.52g of ammonia water and dissolve them in 10mL of water respectively. After fully dissolving, inhale into a 10mL syringe, and fix the syringe on the digital control micro pump; sSimethicone oil, add 0.01wt...

Embodiment 3

[0039] 1) Preparation of microreactor: The PDMS chip is prepared by soft lithography technology. The cross-section of the chip channel is uniformly square, with a side length of 600 μm; the included angle of the raw material adding channel is 45°; the meandering channel has an outer diameter of 2.1 mm and an inner diameter of 1.5 semi-circular channels, the total length is 35mm; the heating pipe is made of PTFE tube, the inner diameter of the tube is 0.6mm, the length of the tube is 15.9m, and the length of the part of the tube wound on the glass rod with an outer diameter of 10mm is 15.1m; one end of the spiral structure PTFE tube and the chip Outlet connection, one end inserted into the Erlenmeyer flask;

[0040] 2) Take 0.35g of 3-aminophenol, 0.75g of formaldehyde, and 0.52g of ammonia water and dissolve them in 10mL of water respectively. After fully dissolving, inhale into a 10mL syringe, and fix the syringe on the digital control micro pump; sSimethicone oil, add 0.05wt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com