Method and application of reducing polylactic acid melt viscosity

A technology of melt viscosity and polylactic acid, which is applied in the field of reducing melt viscosity in the melting process of polylactic acid, can solve the problems of thermal stability restriction, increase processing temperature, influence on mechanical properties, etc., and achieve short melt processing time, Reduce melt viscosity and require simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

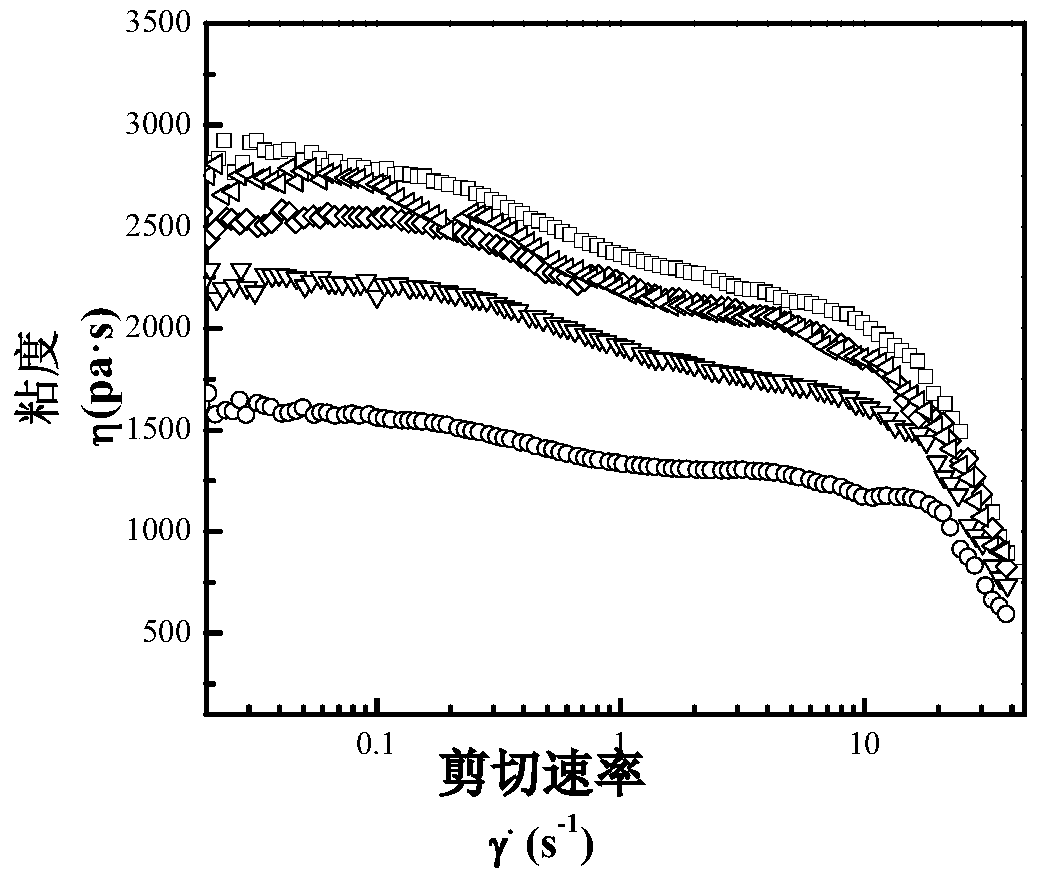

Embodiment 1

[0027] Take 62g of PLA, by volume, the added volume of silica is 0.1% of the volume of polylactic acid, weigh silica filler R974, dry at 60°C for 24 hours, put it into XSS-30 with temperature set at 170°C In the mixing chamber of the torque rheometer, set the rotational speed at 32 rpm, melt and process for 15 minutes, take out the sample and cool it to room temperature 20-25 degrees Celsius to obtain PLA / R0.1%.

Embodiment 2

[0029] Take 62g of PLA, by volume, the added volume of silica is 0.3% of the volume of polylactic acid, weigh silica filler R974, dry at 60°C for 24 hours, put it into XSS-30 with temperature set at 170°C In the mixing chamber of the torque rheometer, set the rotational speed at 32 rpm, melt and process for 15 minutes, take out the sample and cool it to room temperature 20-25 degrees Celsius to obtain PLA / R0.3%.

Embodiment 3

[0031] Take 62g of PLA, by volume, the added volume of silica is 0.5% of the volume of polylactic acid, weigh silica filler R974, dry at 60°C for 24 hours, put it into XSS-30 with temperature set at 170°C In the mixing chamber of the torque rheometer, set the rotational speed at 32 rpm, melt and process for 15 minutes, take out the sample and cool it to room temperature 20-25 degrees Celsius to obtain PLA / R0.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com