A kind of preparation method of polymer adhesive film with adjustable refractive index

An adhesive film and polymer technology, applied in the field of adhesives, can solve the problems of refractive index research of adhesive film, light source interference, damage to optical parts, etc., and achieve the effect of wide storage temperature range, saving bonding time and improving image quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

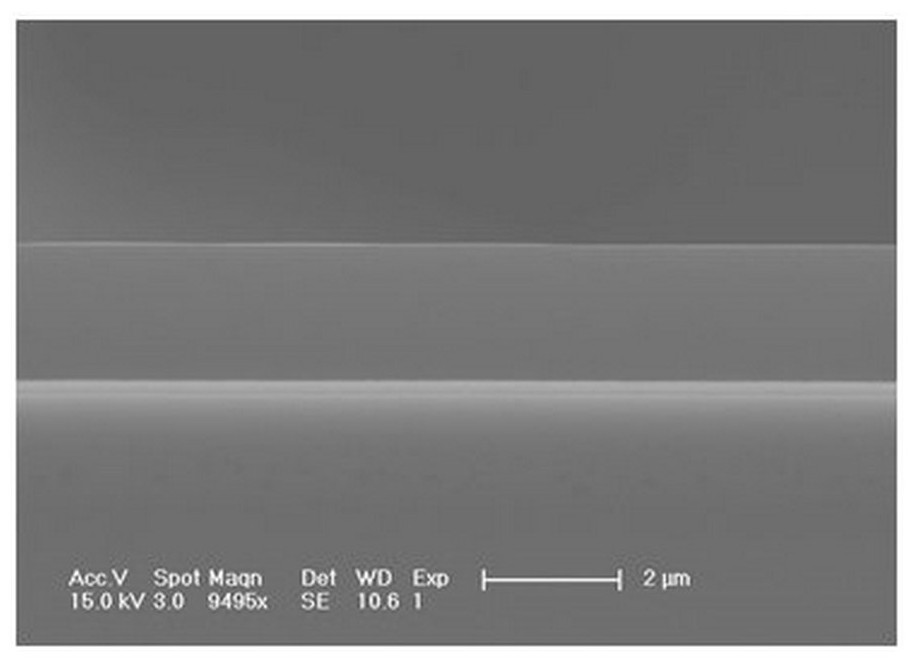

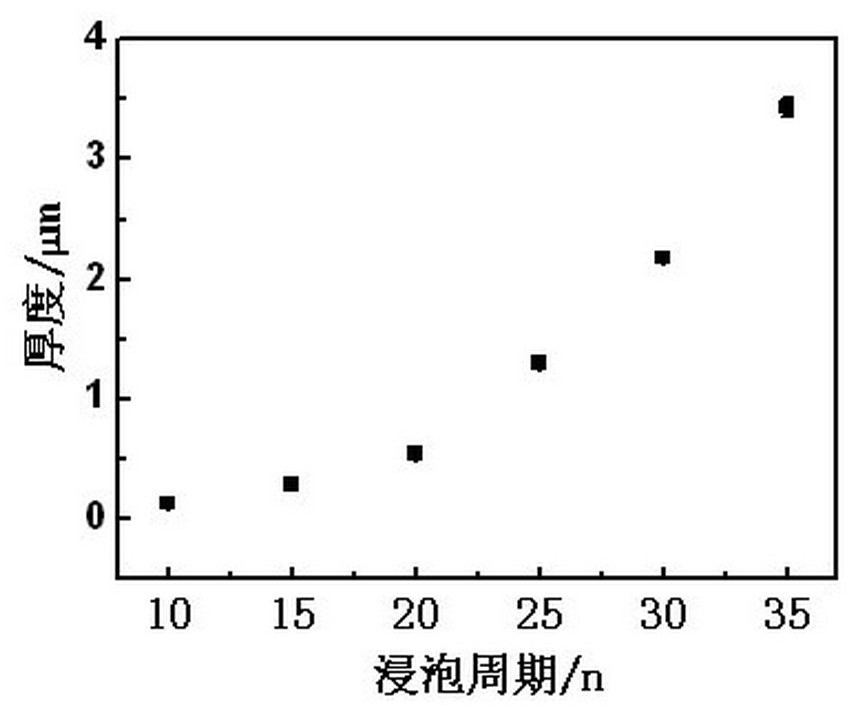

Image

Examples

Embodiment 1

[0044] Embodiment 1 A method for preparing a polymer adhesive film with adjustable refractive index, the polymer adhesive film is PEI / (PAA-PSS), the cationic element A is PEI, and the anionic element B-B 2 B and B 2 It is PAA and PSS; the molar ratio of PSS to PAA-PSS is 0.1:100, and the preparation steps and conditions are as follows:

[0045] (1) Preparation of cationic base PEI solution:

[0046] At room temperature, the molecular weight of 0.1g is 7.5×10 5 The cationic base PEI and 100mL deionized water were placed in the reactor, and stirred evenly to obtain a cationic base PEI solution with a mass volume concentration of 1.0mg / mL; the pH of the solution was adjusted to 9.0 with hydrochloric acid, and it was set aside;

[0047] (2) Preparation of anionic radical PAA-PSS solution

[0048] will be 2.55×10 -4 g molecular weight is 7.5×10 4 The anionic motif PSS and 9.98×10 -2 g molecular weight is 1.0×10 5 The anion element PAA and 100mL deionized water were placed in...

Embodiment 2

[0057] Embodiment 2 A method for preparing a polymer adhesive film with adjustable refractive index, the polymer adhesive film is PDDA / (PAA-PSS), the cationic element A is PDDA, and the anionic element B-B 2 B and B 2 For PAA and PSS, the molar ratio of PSS to PAA-PSS is 50:100, the steps and conditions of preparation are as follows:

[0058] (1) Preparation of cationic radical PDDA solution:

[0059] At room temperature, the molecular weight of 1.5g is 2.5×10 5 The cationic base PDDA and 100mL deionized water were placed in a reactor, and stirred evenly to obtain a cationic base PDDA solution with a mass volume concentration of 15.0mg / mL; the pH of the solution was adjusted to 7.0 with sodium hydroxide, and it was set aside;

[0060] (2) Preparation of anionic radical PAA-PSS solution

[0061] will be 3.6×10 -2 g molecular weight is 1.0×10 6 The anionic motif PSS and 1.4×10 -2 g molecular weight is 2.0×10 3 The anion element PAA and 100mL deionized water were placed in...

Embodiment 3

[0069] Embodiment 3 A method for preparing a polymer adhesive film with adjustable refractive index, the polymer adhesive film is PAH / (PAA-PSS), the cationic element A is PAH, and the anionic element B-B 2 B and B 2 For PAA and PSS, the molar ratio of PSS to PAA-PSS is 25:100, and the preparation steps and conditions are as follows:

[0070] (1) Preparation of cationic radical PAH solution:

[0071] At room temperature, the molecular weight of 1g is 1.7×10 4 Put cationic PAH and 100mL deionized water in a reactor, stir evenly to obtain a cationic PAH solution with a mass volume concentration of 10.0 mg / mL; adjust the pH of the solution to 9.0 with hydrochloric acid, and set aside;

[0072] (2) Preparation of anionic radical PAA-PSS solution

[0073] Convert 4.6×10 -1 g molecular weight is 7.0×10 4 The anionic motif PSS and 5.4×10 -1g molecular weight is 2.0×10 3 The anion element PAA and 100mL deionized water were placed in a reactor, and stirred evenly to obtain a mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com