Roller brush control mechanism and method

A control mechanism and control method technology, which is applied in the field of snow sweeping machinery and sanitation cleaning machinery, can solve problems such as poor road adaptability, unsatisfactory obstacle avoidance effect, complicated lifting control of dragging roller brushes, etc., and achieve good road surface adaptation Unique, compact, powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

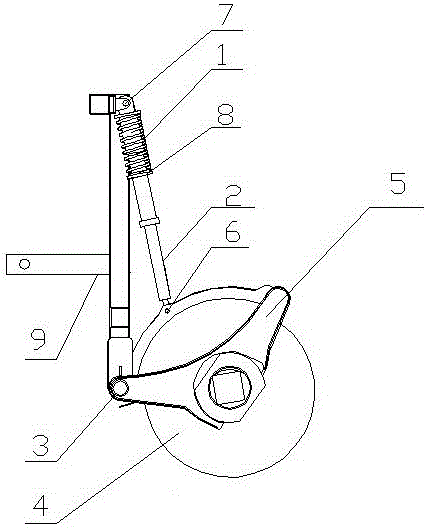

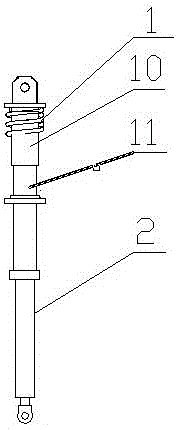

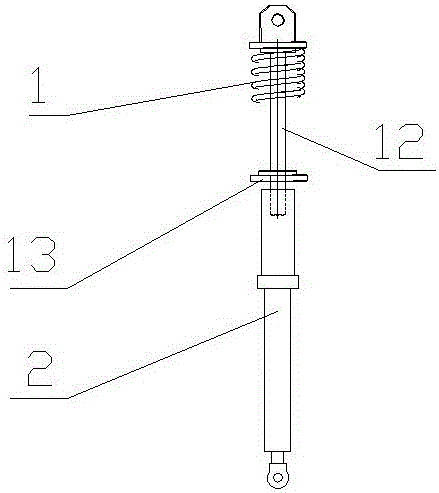

[0021] The elastic telescopic mechanism is formed by the spring 1 and the telescopic mechanism 8, and the oil cylinder 2 is connected with the telescopic mechanism 8 to form a rolling brush control mechanism, and the rolling brush drag frame 9 is installed at the rear of the automobile.

[0022] When the car is running and does not clear the snow, the oil cylinder 2 shrinks. Since the upper end of the telescopic mechanism 8 is fixed on the roller brush drag frame 9 through the A pin 7, the oil cylinder 2 connected with the telescopic mechanism 8 is fixed through the B pin 6. Pulling the brush holder 5 makes the brush holder 5 move upward around the brush holder shaft 3, thereby lifting the roller brush away from the road surface.

[0023] When the car is running and performing snow removal operations, the oil cylinder 2 is extended, so that the brush holder 5 moves downward around the brush holder shaft 3, thereby putting the roller brush on the road.

[0024] When the automob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com